Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat, Density 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||

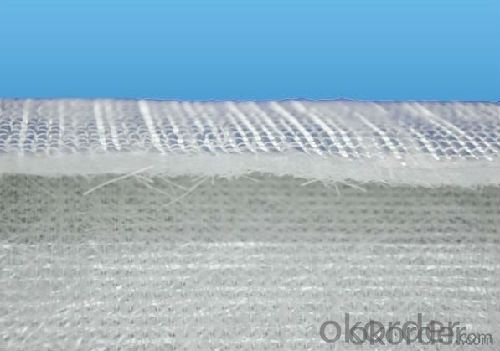

Fiberglass Stitch Combo Mat is a mat made by stitching together with woven roving and a layer of evenly distributed chopped strands.

It consists of two or more layers of fiber glass rovings which are stitch-bonded. one layer of rovings and differene layers of rovings can be oriented differently and have different linear density. the roving specification, number of roving layers, mat width and roll diameter can be customized as per requirement.

This product is widely used in hand lay-up and RTM processes. It is mostly widely used in boat industry, typical end-use application include FRP boat hulls, automotive shell and door, laminates, cooling apparatus and structural shapes. | |||||||||||||||||||||||||||||||||||||||

Product Traits: | |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ

1. How can you guarantee the quality? We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

2. Which delivery term will you usually offer? We usually offer FOB Chongqing, FOB Shenzhen, FOB Shanghai or CIF port (defined by the customer).

| |||||||||||||||||||||||||||||||||||||||

- Q: How does the thickness of fiberglass mat tissue affect its flexibility?

- The thickness of fiberglass mat tissue directly affects its flexibility. Generally, thinner fiberglass mat tissue is more flexible compared to thicker ones. This is because the thickness of the mat tissue determines the amount of resin that can be absorbed and the overall weight of the material. Thinner mat tissue allows for more resin saturation, which increases its flexibility. Additionally, thinner mat tissue is lighter in weight, making it easier to bend and shape. On the other hand, thicker mat tissue is less flexible due to its lower resin absorption capacity and heavier weight. It may require more force or effort to bend or shape thicker mat tissue compared to thinner ones. Therefore, the thickness of fiberglass mat tissue plays a crucial role in determining its flexibility.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Yes, fiberglass mat tissue can be used for insulation in pharmaceutical storage areas. Fiberglass mat tissue is a versatile material that offers excellent thermal insulation properties. It is often used in various industries, including pharmaceuticals, due to its ability to regulate temperature and provide insulation against heat transfer. In pharmaceutical storage areas, maintaining the appropriate temperature is crucial to ensure the integrity and stability of stored medications and vaccines. Fiberglass mat tissue can help create a temperature-controlled environment by reducing heat transfer between different areas and protecting the stored products from external temperature fluctuations. Additionally, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it suitable for pharmaceutical storage areas where cleanliness and hygiene are essential. It can be easily placed between walls, ceilings, and floors to provide a barrier against heat flow, thus maintaining the desired temperature inside the storage area. Moreover, fiberglass mat tissue is a non-combustible material, which adds an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, ensuring the protection of valuable pharmaceutical products and reducing the risk of fire-related accidents. Overall, fiberglass mat tissue is an effective choice for insulation in pharmaceutical storage areas, providing thermal regulation, moisture resistance, cleanliness, and fire safety. It helps maintain the required temperature and ensures the integrity and stability of stored medications and vaccines.

- Q: Can fiberglass mat tissue be used for electrical insulation?

- Fiberglass mat tissue can indeed serve as electrical insulation due to its impressive properties. Composed of fine glass fibers, this non-woven fabric possesses exceptional electrical insulation capabilities. Its ability to endure high temperatures and exhibit a high dielectric strength renders it ideal for a range of electrical applications. For instance, it finds regular use as an insulation material in electrical transformers, motors, generators, and other electrical equipment. By creating a barrier that hinders the passage of electrical current, the fiberglass mat tissue safeguards the components against potential electrical shocks or short circuits. Moreover, it boasts resistance against moisture, chemicals, and UV radiation, thereby further enhancing its suitability for electrical insulation purposes.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The different thickness tolerances for fiberglass mat tissue can vary depending on the specific manufacturer and product specifications. However, in general, fiberglass mat tissue is available in various thickness tolerances ranging from 0.5 millimeters (mm) to 3 mm. The tolerance refers to the acceptable range of thickness variation within a certain product. For example, a fiberglass mat tissue with a thickness tolerance of +/- 0.5 mm means that the actual thickness of the tissue can vary by up to 0.5 mm in either direction from the specified thickness. The specific tolerance required for a particular application depends on the intended use and the level of precision needed. Thicker fiberglass mat tissues with smaller tolerances are often used in applications that require higher strength and durability, such as in the construction industry for reinforcing concrete or in the manufacturing of composite materials. On the other hand, thinner fiberglass mat tissues with larger tolerances may be used in applications where flexibility and conformability are more important, such as in the automotive industry for insulation or soundproofing purposes. It is important to consult the manufacturer's specifications or contact a supplier for accurate information on the available thickness tolerances for fiberglass mat tissue, as they can vary significantly depending on the specific product and supplier.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Special tools may be needed for installing fiberglass mat tissue. These tools may include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment like gloves and goggles to protect the installer from potential dangers. Furthermore, certain installations may necessitate the use of a heat gun or torch to activate or cure the resin. To ensure proper installation and ascertain if any special tools are necessary, it is crucial to carefully read and adhere to the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- Yes, fiberglass mat tissue does have fire-resistant properties. Fiberglass is inherently fire-resistant due to its composition. It is made from a combination of glass fibers and a thermosetting resin, which gives it its fire-resistant properties. When exposed to high temperatures or flames, fiberglass mat tissue does not easily ignite or burn. Instead, it resists the spread of flames and can help to contain a fire. This makes fiberglass mat tissue a suitable material for applications where fire protection is required, such as insulation, fire barriers, and fireproof panels. However, it is important to note that while fiberglass is fire-resistant, it is not completely fireproof and can still melt or burn under extreme conditions.

- Q: Is fiberglass mat tissue resistant to UV radiation?

- Yes, fiberglass mat tissue is resistant to UV radiation. Fiberglass is known for its excellent resistance to UV rays, making it highly suitable for outdoor applications. UV radiation from the sun can cause materials to degrade, discolor, or become brittle over time. However, fiberglass mat tissue is made with a special resin that provides UV stability, allowing it to maintain its strength and integrity even when exposed to sunlight for extended periods. This makes fiberglass mat tissue a popular choice for various outdoor applications such as roofing, boat construction, and exterior cladding, where it is essential to have a material that can withstand the damaging effects of UV radiation.

- Q: What are the key properties of fiberglass mat tissue?

- Fiberglass mat tissue possesses several important properties, making it a versatile material. Firstly, it is composed of fine glass fibers that are randomly oriented and bonded together using a binder. This random orientation gives it greater strength and flexibility compared to other materials. One notable property of fiberglass mat tissue is its high tensile strength. It can endure significant amounts of pulling or stretching forces without breaking, making it perfect for applications that require durability and resistance to mechanical stress. Additionally, fiberglass mat tissue has excellent thermal insulation capabilities. It has a low thermal conductivity, which means it effectively prevents heat transfer. This property makes it ideal for insulation applications, helping to conserve energy and maintain a stable temperature. Another advantage of fiberglass mat tissue is its good chemical resistance. It is not easily affected by exposure to chemicals, acids, or alkaline substances. This makes it a suitable choice for applications like chemical storage tanks or pipes, where resistance to corrosion is crucial. Furthermore, fiberglass mat tissue exhibits outstanding moisture resistance. It does not readily absorb water, making it resistant to rot and decay. This property makes it suitable for outdoor applications or environments with high humidity. Lastly, fiberglass mat tissue is lightweight and easy to handle. It can be easily cut, shaped, and installed, making it a convenient material for various applications. In summary, fiberglass mat tissue possesses key properties such as high tensile strength, thermal insulation capabilities, chemical resistance, moisture resistance, and lightweight. These properties make it a versatile material for use in industries such as construction, automotive, aerospace, and marine.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Woven Roving Compressed Mat, Density 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords