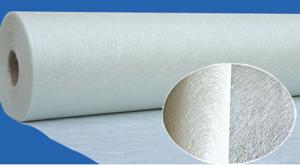

Fiberglass Mat Tissue Woven Roving Combo Mat 1100g(300/500/300)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc.. ◎ Fiberglass combo mat is used the fiberglass roving weaved to enhanced fabric, suitable for all kinds of resin system. Woven roving is a high performance reinforced material, widely used in hand lay-up and mechanical molding products, such as boats, vessels, planes and automotive parts, furniture, sports facilities and other wide range of applications.

| |||||||||||||||||||||||||||||||||||||||

Product Traits | |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. ◎ Low thermal shrinkage | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||

Service Advantages | |||||||||||||||||||||||||||||||||||||||

Quality guarantee for fiberglassneedle mat Reasonable price and best services. Flexible delivery for sample and big order. Many years of trading experience in this fiberglass needle mat

| |||||||||||||||||||||||||||||||||||||||

FAQ

1) which kind of glass fiber sample and materials can you provide?

We can provide the glass fiber and glass fiber down stream products samples of E glass, C glass, ECR glass, High alkali glass. The products include single end roving, assembled roving for different applications( Piping, SMC, panel, winding mill plate) , chop strand for BMC, engineering plastic (PA, PPA, PPT, POM, etc), chop strand mat (from 100gsm-900gsm) for automobile and water tank, etc, woven roving (270gsm-800gsm), surface tissue (25-50gsm), multi-axial fabric of different unit weight.

2) Can you provide glass fiber composite material?

We can provide GFRP profile such as grating, T beam, U beam and other assembles pieces such as GFRP triangle frame, dust bin, fireplace, etc

3) How much sample can you provide and who will bear the sample cost?

We can provide the glass fiber samples not more than 1kg free of change. However, the courier cost must be born by the customer. As to the glass fiber composite materials, we can provide the piece not more than 1kg free of change ( with the existing module). However, the courier cost must be born by the customer. If we need to make a new model, this excludes.

- Q: How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue, a type of thin fiberglass material, plays a crucial role in the production of agricultural equipment. It is primarily used as a reinforcement material in the manufacturing process of agricultural equipment, such as tractors, harvesters, and sprayers. One of the main applications of fiberglass mat tissue in agricultural equipment production is in the construction of structural components. The tissue is often used to reinforce the body panels and chassis, providing strength and durability to the equipment. This reinforcement helps to enhance the overall structural integrity and load-bearing capacity of the agricultural machinery, making it more reliable and capable of withstanding the demanding conditions of agricultural operations. Moreover, fiberglass mat tissue is also used in the production of agricultural equipment for its corrosion resistance properties. Agricultural machinery is often exposed to harsh environments, including chemicals, fertilizers, and the elements. By incorporating fiberglass mat tissue into the manufacturing process, the equipment becomes more resistant to corrosion, extending its lifespan and reducing maintenance costs. Additionally, fiberglass mat tissue is utilized in the production of agricultural equipment to improve its insulation and soundproofing capabilities. By incorporating layers of fiberglass mat tissue between the panels and components, the equipment becomes better insulated against temperature fluctuations, reducing energy loss and improving efficiency. Moreover, the tissue helps to dampen noise and vibration, creating a quieter and more comfortable working environment for operators. In summary, fiberglass mat tissue is a critical component in the production of agricultural equipment. Its reinforcement, corrosion resistance, insulation, and soundproofing properties contribute to the overall performance, durability, and efficiency of agricultural machinery, making it an indispensable material in this industry.

- Q: Can fiberglass mat tissue be used for HVAC ducting?

- HVAC ducting can indeed utilize fiberglass mat tissue. This lightweight substance is formed by bonding glass fibers with resin. Its exceptional thermal insulation qualities render it suitable for HVAC systems that prioritize temperature control. Moreover, fiberglass mat tissue boasts resistance against moisture and chemicals, assuring long-lasting durability in ducting applications. Its installation is hassle-free, and it can be tailored to fit varied duct sizes and shapes. All in all, fiberglass mat tissue emerges as a dependable and effective option for HVAC ducting.

- Q: How is fiberglass mat tissue made?

- Fiberglass mat tissue is made through a process called wet-laid process, which involves several steps. First, glass fibers are created by melting and extruding glass through small holes to form continuous filaments. These filaments are then coated with a sizing agent to improve their handling properties and strengthen the final product. Next, the glass fibers are chopped into short lengths to create a fiber mat. This is usually done using a knife or a rotary chopper. The chopped fibers are then collected and formed into a thin layer on a moving conveyor belt. In parallel to this, a binder solution is prepared by mixing a synthetic resin with water. This solution is then sprayed onto the fiber mat to wet and bind the fibers together. The amount of binder used determines the strength and flexibility of the final product. To ensure uniform distribution of the binder and proper consolidation of the mat, it passes through a series of rollers. These rollers apply pressure to remove excess water, squeeze the fibers together, and promote bonding between the fibers. Once the mat is consolidated and the desired thickness is achieved, it is dried in an oven or through hot air currents. This removes any remaining moisture and cures the binder, transforming it into a solid resin. After drying, the fiberglass mat tissue is wound into rolls for storage or further processing. It can be used as a reinforcing material in various industries, such as construction, automotive, and aerospace, due to its excellent strength, corrosion resistance, and thermal insulation properties.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Special treatment is required for UV resistance when using fiberglass mat tissue. This tissue is composed of fine strands of glass fibers which can be easily damaged by prolonged exposure to ultraviolet (UV) radiation. The degradation of the fibers due to UV rays can result in a reduction in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a unique coating or treatment to the material. This treatment serves to safeguard the fibers from UV radiation and prevent their deterioration. The specific treatment employed may vary based on the intended application and the desired level of UV resistance. Furthermore, it is important to acknowledge that despite the special treatment, fiberglass mat tissue may still experience some degree of UV damage over time. It is therefore advised to minimize direct sunlight exposure whenever possible to ensure the longevity and performance of the material.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue is commonly used in various applications, including but not limited to, the construction industry, automotive manufacturing, and the production of composite materials. It is used as a reinforcement material in the construction of walls, roofs, and floors, providing strength and durability. In the automotive industry, fiberglass mat tissue is used for sound insulation and as a reinforcement material in the production of car parts. Additionally, it is widely utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics, due to its high strength-to-weight ratio and excellent corrosion resistance.

- Q: What is the tear strength of fiberglass mat tissue?

- The ability of fiberglass mat tissue to resist tears or cracks when exposed to external forces is referred to as its tear strength. This characteristic plays a crucial role in determining the durability and performance of fiberglass mat tissue in different applications. Standardized testing methods, such as the ASTM D1922 tear resistance test, are typically used to measure the tear strength of fiberglass mat tissue. This test involves applying a controlled force, usually in the form of a tensile load, to a sample of the material and measuring the amount of force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific requirements of the application. Generally, fiberglass mat tissues are designed to have high tear strength in order to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue finds widespread use in industries like construction, automotive, aerospace, and marine, thanks to its high tear strength and other desirable properties. It is commonly employed as a reinforcement material in composites, providing increased strength and durability to the final product. In summary, the tear strength of fiberglass mat tissue is a vital property that determines its ability to resist tearing or cracking when subjected to applied forces. By ensuring a high tear strength, fiberglass mat tissue can meet the demands of various applications and deliver long-lasting performance.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- The purpose of glass fiber is to make the product more convenient for processing, containing a layer of glass fiber cloth, then the operation process is not easy to damage thermal conductive gasket

- Q: Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used as reinforcement in construction and engineering. It is often used in conjunction with other materials such as resin or concrete to enhance the structural integrity of various components. The high strength-to-weight ratio of fiberglass mat tissue makes it ideal for reinforcing structures such as walls, roofs, and floors. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it suitable for use in various environments. Its versatility and durability make it a popular choice in structural applications.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass veil, is made up of a combination of fiberglass fibers and a binder material. The fiberglass fibers used in the composition are typically made from silica, a naturally occurring mineral. These fibers are known for their high strength and durability. The binder material used in fiberglass mat tissue can vary, but commonly includes substances like urea-formaldehyde, acrylic, or polyester resins. The role of the binder is to hold the fiberglass fibers together and provide structural integrity to the mat. In addition to the fiberglass fibers and binder, other additives may be included in the composition of fiberglass mat tissue. These additives can include substances such as pigments, fire retardants, or coatings, depending on the specific application and desired properties of the mat. Overall, the composition of fiberglass mat tissue is a combination of fiberglass fibers and a binder material, with additional additives depending on the intended use. This composition allows fiberglass mat tissue to possess excellent strength, flexibility, and resistance to various environmental factors, making it a versatile material used in various industries such as construction, automotive, aerospace, and marine.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 1100g(300/500/300)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords