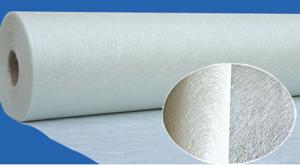

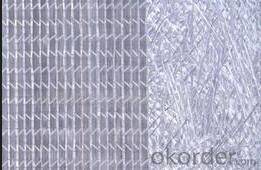

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1700gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Main Features of the woven roving combo mat

Fiber level unfolded without cross, high density, high utilizing rate.

Multi-layer finished one time, decrease layer and enhance efficiency.

Woven Roving Combo Mat Specification

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue at high temperatures can vary depending on several factors such as the specific composition of the tissue, the manufacturing process, and the conditions under which it is tested. Generally, fiberglass mat tissue exhibits good impact resistance at high temperatures due to the inherent strength and durability of fiberglass materials. Fiberglass is known for its excellent mechanical properties, including high tensile strength and stiffness, which contribute to its overall impact resistance. At high temperatures, fiberglass mat tissue is typically able to maintain its structural integrity and resist cracking or breaking under impact. This is because the fiberglass fibers are designed to withstand high temperatures and do not soften or deform easily. However, it is important to note that the impact resistance of fiberglass mat tissue can be influenced by other factors such as the presence of any additives or binders used in the manufacturing process. Some additives or binders may reduce the impact resistance or make the tissue more susceptible to damage at high temperatures. To determine the specific impact resistance of a particular fiberglass mat tissue at high temperatures, it is important to consult the manufacturer's specifications or conduct specific tests under controlled conditions. These tests can provide more accurate information on how the material will perform under impact at elevated temperatures.

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant. Fiberglass mat tissue is made from fine glass fibers that are randomly oriented and bound together with a resin binder. This composition allows the material to exhibit excellent resistance to a wide range of chemicals including acids, alkalis, solvents, and oils. It is commonly used in industries such as chemical processing, petrochemicals, and wastewater treatment where exposure to various chemicals is common. The chemical resistance of fiberglass mat tissue makes it a suitable choice for applications requiring corrosion resistance and long-term durability.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q: How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue is used in the production of agricultural equipment as a reinforcing material. It is typically applied to the surface of the equipment, such as tractor bodies or storage tanks, to provide strength, durability, and resistance to environmental elements. The fiberglass mat tissue helps in enhancing the structural integrity of the equipment, making it more reliable and long-lasting for agricultural applications.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- Yes, fiberglass mat tissue is suitable for insulation in high-rise buildings. It is commonly used as an insulating material due to its excellent thermal and sound insulation properties. Fiberglass mat tissue is lightweight, fire-resistant, and has a high melting point, making it a safe and effective choice for insulating high-rise buildings. Additionally, it is easy to install and offers good resistance against moisture and mold, ensuring long-term performance and energy efficiency.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- I know that GLPOLY has a heat conductive gel gasket that looks like an PCB circuit board for an uneven interface

- Q: Does fiberglass mat tissue require any special handling or storage requirements?

- Fiberglass mat tissue necessitates specific care and storage measures. To begin with, it is imperative to handle fiberglass mat tissue delicately in order to prevent any harm or breakage. The tissue should be treated with gentleness and not pulled or dropped, as this may result in the separation or damage of the fibers. It is also advisable to wear gloves and protective clothing while handling fiberglass mat tissue to avoid any skin irritation or injuries. Regarding storage, it is crucial to keep fiberglass mat tissue in a clean and dry environment. Shielding it from moisture is of utmost importance, as water exposure can weaken the fibers and diminish its efficacy. Therefore, it is preferable to store fiberglass mat tissue in sealed, moisture-proof packaging or in a dry room with controlled humidity levels. Furthermore, fiberglass mat tissue should be kept away from direct sunlight and extreme temperatures. High temperatures can cause the resin in the tissue to cure prematurely, while excessive cold can make it brittle and more susceptible to damage. Hence, it is recommended to store fiberglass mat tissue in a cool and shaded area to maintain its quality and ensure its longevity. By adhering to these specialized handling and storage requirements, fiberglass mat tissue can be safeguarded and preserved in its optimal condition, ready for utilization in various industries such as construction, insulation, or automotive.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages of using fiberglass mat tissue in construction. Firstly, it provides excellent strength and durability, making it highly resistant to impacts and weather conditions. Additionally, it has a high tensile strength, allowing it to withstand heavy loads without deformation. Fiberglass mat tissue is also lightweight, making it easier to handle and transport. Moreover, it is non-combustible and provides good thermal insulation properties, enhancing the overall safety and energy efficiency of the construction. Lastly, fiberglass mat tissue is cost-effective, as it requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements.

- Q: What are the key properties of fiberglass mat tissue?

- The key properties of fiberglass mat tissue include high strength and durability, excellent fire resistance, good thermal insulation properties, and resistance to chemicals and moisture. Additionally, it is lightweight, easy to handle and install, and offers good dimensional stability.

Send your message to us

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1700gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords