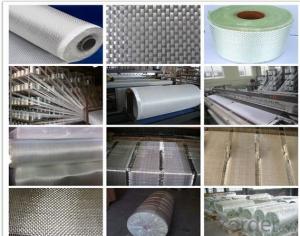

Roll Of Fiberglass Cloth

Roll Of Fiberglass Cloth Related Searches

Fiberglass Cloth Roll Rolls Of Fiberglass Mat Fiberglass Roll Insulation Fiberglass Yarn Fiberglass Fabric Fiberglass Cloth Philippines Fiberglass Woven Fabric Epoxy Resin And Fiberglass Cloth Fiberglass Roving Fibreglass Fabric 1708 Fiberglass Roll Fiberglass Woven 1708 Fiberglass Cloth Carbon Fiber Cloth Fiberglass Insulation Blanket Car Fiberglass Fiberglass Sheets For Roofing Woven Fibreglass Fiberglass Thermal Insulation Fiberglass Woven Roving Combo Mat Fiberglass Roof Philippines Fiberglass Roll Up Garage Doors Fiberglass Drywall Fiberglass Wall Insulation Fiberglass Patio Roof Fiberglass Filament Winding Machine Fiberglass Strands In Skin Large Rolls Of Plastic Sheeting Fiber Glass Mat Fibreglass Mesh TapeRoll Of Fiberglass Cloth Supplier & Manufacturer from China

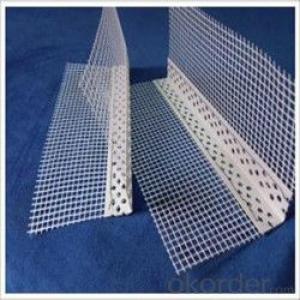

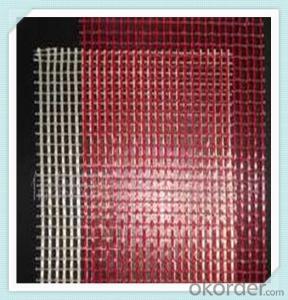

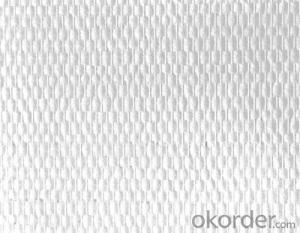

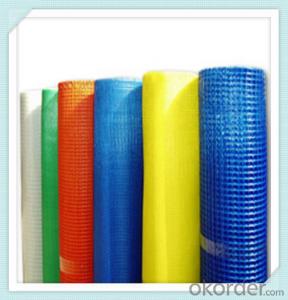

Roll of Fiberglass Cloth is a versatile material that consists of woven glass fibers, offering a range of applications in various industries. This product is known for its strength, durability, and resistance to heat, making it ideal for use in construction, automotive, and aerospace sectors. Fiberglass cloth can be used for insulation, reinforcement, and as a component in composite materials, providing a reliable solution for numerous projects.The roll of fiberglass cloth is widely utilized in various applications, such as pipe insulation, boat building, and creating molds for casting. Its ability to withstand high temperatures and resist corrosion makes it a popular choice for industrial use. Additionally, it can be easily cut and shaped to fit specific requirements, making it a convenient option for both professionals and DIY enthusiasts.

Okorder.com is a reputable wholesale supplier of roll of fiberglass cloth, boasting a large inventory to cater to the demands of different customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the roll of fiberglass cloth they provide meets the highest standards. This makes them a reliable source for businesses and individuals seeking to purchase this product in bulk for their projects and applications.

Hot Products