Fireproof Fiberglass Mat Tissue Glasswool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

h): Hydrophobicity

Hydrophobicity glass wool in panel wall bears 99% Hydrophobicity rate. It can easily get dry naturally, which ensure its long-term heat preservation perporty.

i): Light in weight

Glass wool bears good heat preservation and soundproofing property. It’s low density product can meet energy saving requirement. Thus it helps to decrease the weight of building and makes the construction more expedite.

k): construction and installation property

Glass wool, with slender fiber and no dregs, can avoid the scuffing or pruritus irritation.

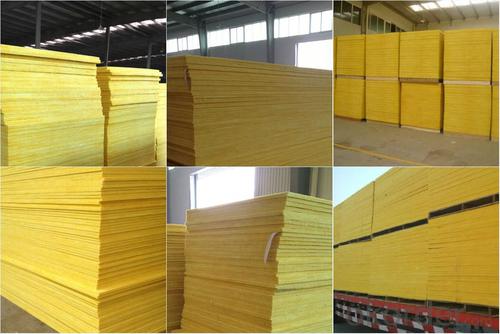

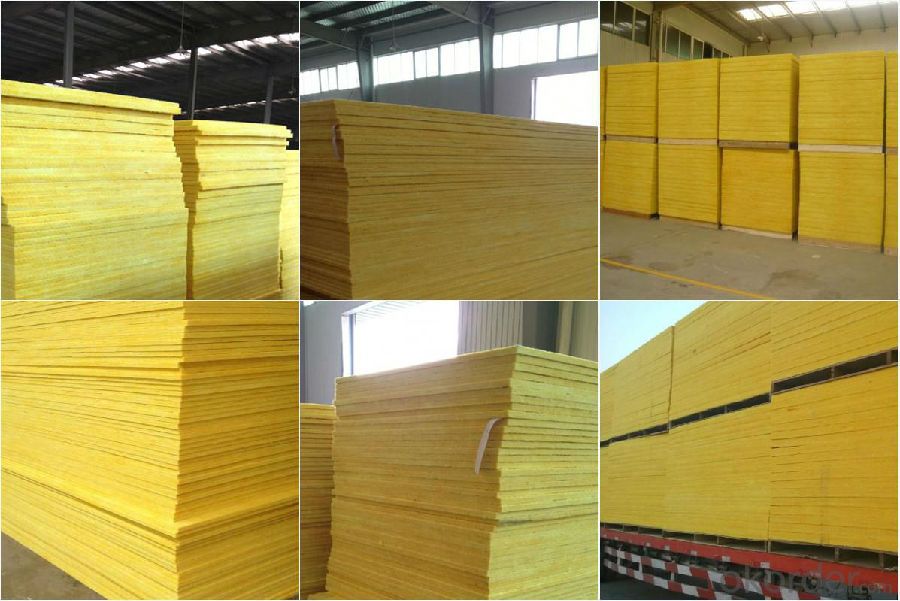

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue easy to install?

- Yes, fiberglass mat tissue is relatively easy to install. It is a lightweight and flexible material that can be easily cut and shaped to fit any surface. It can be applied using various methods such as spraying, rolling, or brushing on adhesive. The tissue is also self-adhesive, which makes it even easier to install as it can easily stick to the desired surface. Additionally, fiberglass mat tissues are typically designed to be water-resistant and provide excellent insulation properties, making them a popular choice for a wide range of applications. Overall, with proper preparation and following the manufacturer's instructions, installing fiberglass mat tissue can be a straightforward and hassle-free process.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- No, fiberglass mat tissue is not typically used for pipe insulation. Fiberglass mat tissue is a thin material that is commonly used for reinforcing purposes in various industries. It is not designed to provide thermal insulation or to prevent heat loss in pipes. For pipe insulation, materials such as foam, mineral wool, or fiberglass pipe insulation are more commonly used. These materials are specifically designed to provide thermal insulation and protect pipes from heat loss, condensation, and freezing.

- Q: Is fiberglass mat tissue suitable for wastewater treatment applications?

- Yes, fiberglass mat tissue is suitable for wastewater treatment applications. It is commonly used in the construction of wastewater treatment tanks and pipes due to its corrosion resistance, durability, and ability to withstand harsh chemical environments. Additionally, fiberglass mat tissue is non-reactive to biological and chemical elements present in wastewater, making it an ideal material for such applications.

- Q: How does the thickness of fiberglass mat tissue affect its flexibility?

- The flexibility of fiberglass mat tissue is directly influenced by its thickness. In general, thinner mat tissue exhibits greater flexibility in contrast to thicker ones. This is primarily because the thickness of the mat tissue regulates the level of resin absorption and the overall weight of the material. Thinner mat tissue allows for a higher saturation of resin, thereby enhancing its flexibility. Moreover, the reduced weight of thinner mat tissue facilitates easier bending and shaping. Conversely, thicker mat tissue is less flexible due to its lower capacity for resin absorption and heavier weight. Consequently, bending or shaping thicker mat tissue may necessitate more force or effort when compared to thinner counterparts. Hence, the thickness of fiberglass mat tissue plays a pivotal role in determining its flexibility.

- Q: What are the different weights available for fiberglass mat tissue?

- Various industries, including construction, automotive, and marine, utilize fiberglass mat tissue extensively. This versatile material is available in different weights or thicknesses to meet various applications and specifications. The weight of fiberglass mat tissue is typically measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the available weights for fiberglass mat tissue range from approximately 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or higher. The weight of the tissue directly affects its strength, rigidity, and durability. For applications that require a high degree of flexibility and conformability, lightweight fiberglass mat tissue weighing around 30-50 gsm (1-1.5 oz/yd²) is commonly used. These lighter weight tissues are often employed in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, typically falling within the range of 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), strikes a balance between flexibility and strength. It finds frequent use in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are of utmost importance. For applications that demand exceptional strength and rigidity, heavyweight fiberglass mat tissue weighing between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more is ideal. This type of tissue is commonly employed in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are critical. It is important to recognize that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In certain cases, custom weights can be manufactured to meet unique project needs. In summary, fiberglass mat tissue is available in a range of weights to accommodate diverse applications. Selecting the appropriate weight is essential to ensuring optimal performance and long-term durability in various industries.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Automotive panel repairs can be effectively carried out using fiberglass mat tissue. This material is known for its versatility and durability, making it a popular choice in the automotive industry. It proves particularly useful in reinforcing and restoring weakened or damaged areas on automotive panels. By providing a strong and stable foundation, fiberglass mat tissue is capable of repairing dents, cracks, and holes in panels. Its pliability allows for easy shaping and molding to fit the contour of the panel. Furthermore, fiberglass mat tissue's resistance to rust and corrosion makes it a reliable option for automotive repairs that must endure harsh weather conditions and road debris. Overall, fiberglass mat tissue is widely utilized due to its strength, durability, and versatility, making it an ideal choice for automotive panel repairs.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing damaged fiberglass structures. Fiberglass mat tissue is a versatile material that is often used in the construction and repair of fiberglass structures. It is a thin and flexible material that can be easily molded and shaped to fit the contours of the damaged area. Additionally, fiberglass mat tissue is known for its high strength and durability, making it an excellent choice for reinforcing and strengthening damaged fiberglass structures. It is commonly used in applications such as repairing cracks, holes, and other damages in boats, car bodies, and other fiberglass products. Furthermore, fiberglass mat tissue can be easily bonded to the damaged area using epoxy or polyester resin, providing a strong and long-lasting repair. Overall, fiberglass mat tissue is an effective and reliable solution for repairing damaged fiberglass structures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass bathtubs?

- Fiberglass bathtubs can be repaired using fiberglass mat tissue. This tissue is a flexible and thin material used to strengthen and reinforce fiberglass surfaces. It is commonly employed in the restoration and repair of various fiberglass products, bathtubs included. To create a durable and sturdy repair, the damaged area is covered with the mat tissue and a layer of resin. This procedure helps fortify weakened or damaged sections of the bathtub, restoring its integrity and preventing further harm. Nevertheless, the success of the repair hinges on the extent of the damage and the expertise of the individual conducting the repair. To achieve optimal results, it is advisable to seek professional advice or adhere to the manufacturer's instructions.

- Q: What is the chemical resistance of fiberglass mat tissue?

- The excellent chemical resistance of fiberglass mat tissue stems from the inherent properties of the fiberglass material. Typically, the mat tissue consists of woven or bound glass fibers, forming a protective barrier against a diverse array of chemicals. The glass fibers themselves possess a high resistance to corrosion, rendering fiberglass mat tissue suitable for use in environments where chemical exposure is a concern. The chemical resistance of fiberglass mat tissue can vary based on the specific resin or binder used in the manufacturing process. Various types of resins may offer superior resistance to certain chemicals, while others may be more susceptible to degradation. It is crucial to consider the specific chemicals that will come into contact with the fiberglass mat tissue and choose a compatible resin or binder accordingly. In general, fiberglass mat tissue is renowned for its ability to withstand acids, alkalis, solvents, and other commonly found industrial and commercial chemicals. It can endure exposure to a wide range of corrosive substances, making it a versatile and long-lasting material for various applications. Nevertheless, it is important to note that prolonged exposure to highly concentrated or aggressive chemicals may eventually result in some degradation or deterioration of the fiberglass mat tissue. Therefore, it is imperative to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

Send your message to us

Fireproof Fiberglass Mat Tissue Glasswool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords