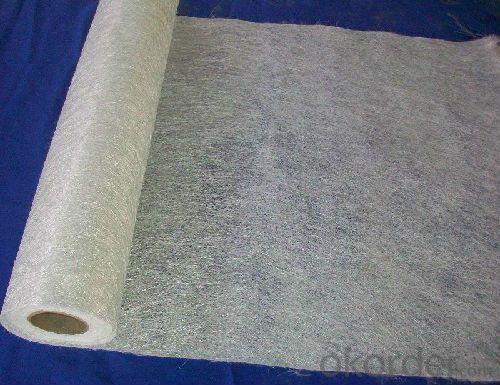

E or C Glass Fiberglass Mat Tissue Surface Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 72000m2 m²

- Supply Capability:

- 1440000m2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

2.Characteristics

Fast breakdown in styrene

Fiber dispersed evenly

Low binder content

Superior acid corrosion resistance

Area Weight 30+/-3 Binder Content % 6-9 Tensile Strength MD N/125px ≥35 Soaking time S ≤10 Moisture content % ≤0.5 Width length mm 1270 Roll Diameter m 300 Paper Core Internal Dia mm 76

3.SpecificationsItem

Unit

Specification

g/m2

Special specification can be produce according to customer requirements.

4.FAQ

a.Pacage

Each Surface Tissue is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 330mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Product storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

- Q: Can fiberglass mat tissue be used for architectural sculptures?

- Yes, fiberglass mat tissue can be used for architectural sculptures. It is a versatile material that can be shaped and molded to create intricate and detailed sculptures. It is also lightweight, durable, and resistant to weather and environmental conditions, making it suitable for outdoor installations. Additionally, fiberglass mat tissue can be easily painted or coated with various finishes to achieve the desired aesthetic.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Indeed, fiberglass mat tissue proves to be suitable for aerospace applications. This lightweight and robust material finds extensive use in the aerospace industry for various purposes. It is frequently employed as a reinforcing material in composite structures, including aircraft wings, fuselages, and other components. The exceptional strength-to-weight ratio of fiberglass mat tissue makes it a favorable choice for aerospace applications, aiding in the reduction of overall aircraft weight without compromising structural integrity. Furthermore, fiberglass mat tissue exhibits resistance to corrosion and can withstand extreme temperatures, both of which are crucial considerations in aerospace environments. In conclusion, fiberglass mat tissue is a versatile material that meets the rigorous requirements of aerospace applications and is widely embraced within the industry.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Yes, fiberglass mat tissue does provide good acoustical performance. It has excellent sound absorption properties due to its fibrous composition, which helps reduce echo and improve overall sound quality in a given space.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is commonly used in the production of shower enclosures due to its excellent properties and benefits. It is a thin and flexible material made up of fine glass fibers that are randomly distributed and bonded together with a resin binder. In the production process of shower enclosures, fiberglass mat tissue is primarily utilized as a reinforcement material. It is often applied to the surface of the enclosure structure to enhance its strength, durability, and resistance to cracking or breaking. Firstly, the fiberglass mat tissue is cut and sized to fit the specific dimensions of the shower enclosure. It is then carefully laid or applied onto the surface of the enclosure, usually through a process called hand lay-up or spray-up. The mat tissue is positioned strategically to cover all the critical areas that require reinforcement, such as corners, edges, and joints. Once the mat tissue is in place, a resin, typically polyester or epoxy, is applied over it. The resin infiltrates the fiberglass mat tissue and bonds with the fibers, creating a solid and robust composite structure. This resin-fiberglass combination provides additional strength and stability to the shower enclosure, making it more resistant to impact, stress, and environmental factors like water and humidity. Moreover, fiberglass mat tissue also contributes to the overall aesthetics of the shower enclosure. It can help create a smooth and uniform surface finish, eliminating imperfections and creating a visually appealing appearance. The mat tissue can be easily molded or shaped to match different designs and styles, enabling manufacturers to produce shower enclosures with various shapes, sizes, and patterns. In summary, fiberglass mat tissue plays a crucial role in the production of shower enclosures by providing reinforcement, strength, durability, and aesthetic benefits. It is a versatile material that enhances the overall performance and visual appeal of the enclosures, ensuring they can withstand daily use and maintain their quality over time.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. It should be handled with care to avoid any damage or breakage as it can easily tear or become compromised. It is advisable to use proper packaging and secure the material to prevent movement or shifting during transportation. Additionally, protective measures such as wearing gloves, masks, and safety glasses should be taken to avoid any potential irritation or respiratory discomfort caused by the fiberglass fibers.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The different thickness tolerances for fiberglass mat tissue can vary depending on the specific product and manufacturer. However, common thickness tolerances range from +/- 0.001 inches to +/- 0.005 inches.

- Q: Can fiberglass mat tissue be used for wind turbine blades?

- Yes, fiberglass mat tissue can be used for wind turbine blades. It is commonly used as a reinforcement material in wind turbine blade manufacturing due to its high strength, lightweight nature, and excellent corrosion resistance.

- Q: Is fiberglass mat tissue suitable for insulation in industrial applications?

- Yes, fiberglass mat tissue is suitable for insulation in industrial applications. Fiberglass mat tissue is a lightweight and flexible material that offers excellent thermal insulation properties. It can effectively trap and retain heat, making it ideal for insulating industrial equipment and machinery. Additionally, it has good fire resistance properties, which is crucial in industrial settings where the risk of fire is higher. Fiberglass mat tissue is also resistant to corrosion, moisture, and chemicals, ensuring its durability and longevity in industrial applications. Overall, its thermal insulation capabilities, fire resistance, and resistance to various environmental factors make fiberglass mat tissue a suitable choice for insulation in industrial applications.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages of using fiberglass mat tissue in construction. Firstly, it provides excellent strength and durability, making it highly resistant to impacts and weather conditions. Additionally, it has a high tensile strength, allowing it to withstand heavy loads without deformation. Fiberglass mat tissue is also lightweight, making it easier to handle and transport. Moreover, it is non-combustible and provides good thermal insulation properties, enhancing the overall safety and energy efficiency of the construction. Lastly, fiberglass mat tissue is cost-effective, as it requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements.

Send your message to us

E or C Glass Fiberglass Mat Tissue Surface Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 72000m2 m²

- Supply Capability:

- 1440000m2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords