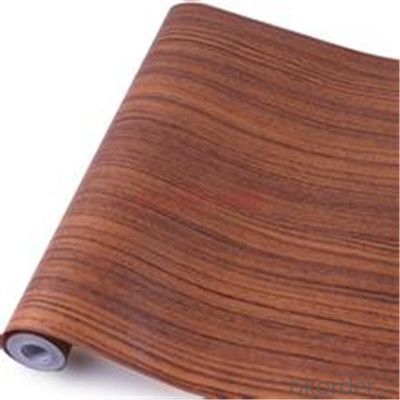

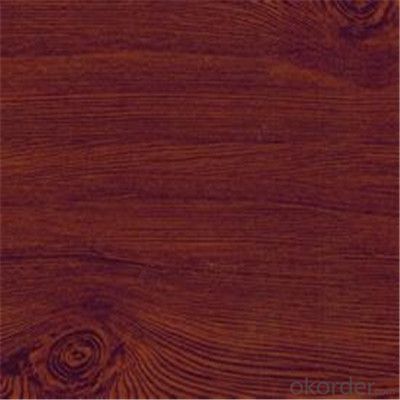

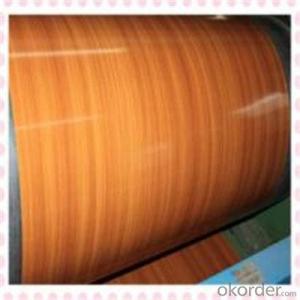

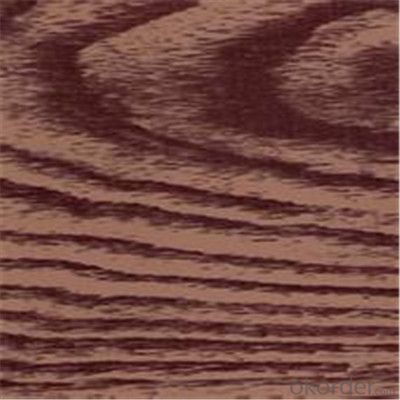

Wood Grain Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of PPGI:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors |

Specifications of PPGI:

1) Steel buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, doors,window frames etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks etc.

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils contribute to the renewable energy equipment industry by playing a crucial role in the manufacturing of various renewable energy components. They are used to create structural frames, support structures, and brackets for wind turbines, solar panels, and other renewable energy systems. Additionally, steel coils are essential in the production of electrical transformers and transmission lines, which are integral to the distribution of renewable energy. Overall, steel coils provide the strength, stability, and durability required for the efficient and long-lasting operation of renewable energy equipment.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: How are steel coils used in the production of heating systems?

- Steel coils are used in the production of heating systems in various ways. One of the main uses of steel coils in heating systems is in the construction of heat exchangers. Heat exchangers play a crucial role in transferring heat from one medium to another within the heating system. The steel coils are typically formed into a series of tubes or fins, which provide a large surface area for efficient heat transfer. In a typical heating system, hot gases or liquids pass through these steel coils, while another medium, such as air or water, flows over or through the coils. This allows for the transfer of heat energy from the hot medium to the cooler medium, thereby effectively heating the air or water for distribution throughout the heating system. Another use of steel coils in heating systems is for the production of radiant heating panels or floor heating systems. In these applications, the steel coils are typically embedded within a panel or underneath the flooring. When electricity or hot water is passed through the coils, they heat up, radiating heat to the surrounding environment. This type of heating system is particularly efficient and provides a comfortable and even distribution of heat. Furthermore, steel coils are also used in the manufacturing of heating system components such as boilers, furnaces, and heat pumps. These components often require the use of steel coils for their heat transfer capabilities and durability. The coils are integrated into the design of these heating system units to ensure efficient and reliable heat generation and distribution. Overall, steel coils play a crucial role in the production of heating systems by enabling efficient heat transfer, providing durability, and facilitating the generation and distribution of heat.

- Q: Why is steel used for building purpose and not any other metal?

- Steel is used for building purpose because of its steadfast quality. The steel has an intense resistance which renders it completely immune to dangers of corrosion, climatic variations, weather fluctuations and other environmental hazards, thereby making it the most suitable metal for exterior surface of the building. Internal structure of steel also helps the building to have strength at the core which enables it to stand erect for a longer time.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: Is there any noticable or perceived difference between smoking out of a pipe with a brass screen and a stainless steel screen?

- Stainless Steel Pipe Screens

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils utilized in the energy sector may differ depending on the specific application and requirements. However, typical dimensions for steel coils in the energy sector encompass a thickness range of 0.5mm to 5.0mm, with widths that usually span from 600mm to 2000mm. The diameter of the coil can also vary, with commonly employed sizes ranging from 1000mm to 2200mm. These dimensions are carefully selected to ensure that the coils can be easily transported, processed, and employed in various energy sector applications, such as power plants, oil and gas pipelines, and renewable energy projects. It is important to emphasize that these dimensions are not fixed and can be tailored according to specific project requirements.

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Typically, okorder /

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Yes ,i think so. The two most useful properties of the metal form are corrosion resistance, and the highest strength-to-weight ratio of any metal.[4] In its unalloyed condition, titanium is as strong as some steels, but 45% lighter.[5] There are two allotropic forms[6] and five naturally occurring isotopes of this element; 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).[7] Titanium's properties are chemically and physically similar to zirconium.

Send your message to us

Wood Grain Printing Galvanized PPGI Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords