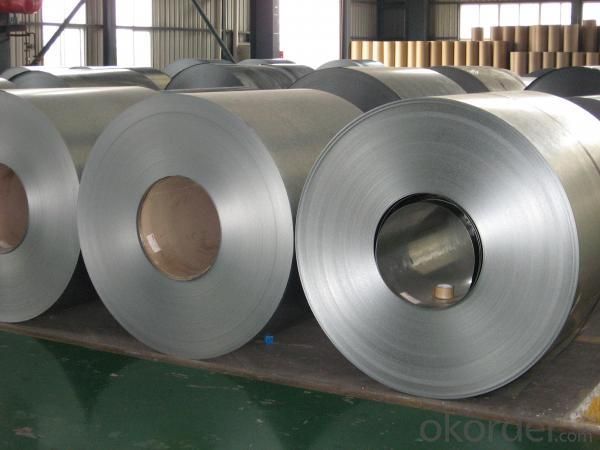

Best Quality For Galvalume Steel Coil AZ150 From China

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Of Galvalume Steel Coil AZ150

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Galvalume Steel Coil AZ150

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Galvalume Steel Coil AZ150

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Galvalume Steel Coil AZ150

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

Packaging & Delivery Of Galvalume Steel Coil AZ150

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q: What are the common quality control measures for steel coils?

- Some common quality control measures for steel coils include inspection for surface defects such as scratches, dents, or unevenness, checking for dimensional accuracy and thickness consistency, testing for mechanical properties such as tensile strength and hardness, conducting chemical composition analysis, and ensuring proper packaging and labeling of the coils.

- Q: What are the major global steel coil markets?

- The major global steel coil markets include countries such as China, the United States, India, Japan, Germany, South Korea, and Russia, among others. These countries have a significant demand for steel coil due to their large manufacturing and construction sectors.

- Q: How are steel coils used in the manufacturing of automotive wheels?

- Steel coils are used in the manufacturing of automotive wheels by being processed and shaped into the necessary components such as rims and spokes. These coils are cut, formed, and welded to create the desired wheel design, ensuring durability and strength for safe and reliable use on vehicles.

- Q: how is stainless steel made? what are the things used in making it?

- There are 3 basic stainless steels. The Martinsitic, the ferritic, and the Austinistic. The spelling may be wrong on all of them. (Got out of school in 1966 with my metallurgy in 1965. The Ferritic is magnetic and has some resistance to corrosion but the Martinsitic is much more resistant to corrosion. The Austinitic stainless is very resistant to corrosion. The differences are the amount of Chrome and Nickel in the batches. The Austinitic has an 18/8 ratio of Chromium and Nickel with the rest Iron and minor ingredients. The carbon content is very important and these steels are often made in small batches with close monitoring of composition and carbon content. Scrap metals are frequently used with the chrome and nickel being added as carefully selected scrap or even fresh crude stocks. Electric melting is frequent to avoid contamination.

- Q: How do steel coils contribute to the energy infrastructure sector?

- The energy infrastructure sector heavily relies on steel coils, which are essential for constructing and maintaining various energy-related structures and equipment. To begin, steel coils are extensively employed in manufacturing pipelines, the lifelines of the energy industry. These pipelines transport oil, natural gas, and other energy resources across long distances, guaranteeing a consistent supply to power plants and other energy facilities. The use of steel coils in producing seamless and welded pipes ensures high strength, durability, and resistance to corrosion, making them well-suited for handling the challenging conditions of energy transportation. Apart from pipelines, steel coils are also used in the production of storage tanks for oil, natural gas, and other fuels. These tanks play a crucial role in storing large quantities of energy resources, ensuring an uninterrupted supply even during periods of high demand. By utilizing steel coils to fabricate the tank shells, the necessary strength and structural integrity are achieved, enabling them to withstand the pressure and environmental factors associated with energy storage. Moreover, steel coils play a vital role in the construction of power plants and other energy infrastructure facilities. They are utilized in manufacturing structural components like beams, columns, and supports, which provide the foundation and stability required for the safe operation of these facilities. Additionally, steel coils contribute to the production of equipment such as turbines, generators, and transformers, which are essential for converting energy into usable forms and distributing it to end-users. Furthermore, steel coils are employed in the construction of transmission towers and electrical grids. These structures and networks are responsible for transmitting electricity from power plants to residential, commercial, and industrial consumers. By using steel coils to manufacture the towers and poles that support high-voltage transmission lines, their stability and reliability in transmitting electricity over long distances are ensured. In conclusion, steel coils are irreplaceable in the energy infrastructure sector, providing the necessary materials for constructing, maintaining, and operating pipelines, storage tanks, power plants, transmission towers, and electrical grids. Their strength, durability, and resistance to corrosion make them the ideal choice for withstanding the demanding conditions of the energy industry, thereby ensuring a reliable and efficient energy supply to meet the growing needs of society.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils can vary depending on a variety of factors including the type of coating, environmental conditions, and usage. However, with proper maintenance and protection, a well-applied coating can typically last anywhere from 10 to 30 years.

- Q: How are steel coils inspected for straightness using laser alignment?

- Steel coils are inspected for straightness using laser alignment through a precise and automated process. Laser alignment technology offers a non-contact method to measure the straightness of steel coils with high accuracy and efficiency. Firstly, the steel coil is placed on a conveyor system that moves it through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for the straightness measurement. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a laser beam that is perfectly straight and parallel to the desired alignment. The receiver unit, placed on the opposite side of the coil, captures the laser beam and analyzes its position. As the coil moves through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This deviation is calculated by analyzing the position of the laser beam at multiple points along the coil's width. The laser alignment system is connected to a computerized control system that processes the data received from the receiver unit. The control system performs complex calculations to determine the straightness of the coil based on the laser beam's position. Any variations or deviations from the desired straight line are recorded and analyzed by the control system. The inspection data can be presented in real-time, allowing operators to monitor the straightness of the steel coil during the inspection process. Using laser alignment for steel coil inspection offers several advantages. It provides highly accurate measurements, ensuring that even minor deviations from straightness are detected. The non-contact nature of laser alignment eliminates the need for physical contact with the coil, reducing the risk of damage or contamination. Additionally, the automated process saves time and increases efficiency compared to manual inspection methods. Overall, laser alignment technology is a reliable and efficient method for inspecting the straightness of steel coils. It ensures that only coils meeting the required straightness criteria are passed, contributing to the quality control of steel manufacturing processes.

- Q: What are the common surface finishes available for steel coils?

- There are several common surface finishes available for steel coils, depending on the desired application and aesthetic requirements. One of the most common surface finishes is hot-dip galvanized, which involves coating the steel coil with a layer of zinc. This finish provides excellent corrosion resistance and is commonly used in outdoor applications where the steel is exposed to moisture and harsh weather conditions. Another popular surface finish is electro-galvanized, which is achieved by applying a thin layer of zinc to the steel coil through an electroplating process. This finish also provides good corrosion resistance but is generally not as durable as hot-dip galvanized. Additionally, steel coils can be coated with a layer of paint or polymer to enhance their appearance and provide additional protection against corrosion. These coatings can be applied in various colors and finishes, such as matte or glossy, to suit specific aesthetic requirements. Furthermore, steel coils can undergo a process called mill finish, which involves leaving the steel in its raw and untreated state. This finish is often used when the steel coil will undergo further processing or coating at a later stage. Other surface finishes for steel coils include stainless steel finish, which is achieved through a passivation process to enhance the steel's resistance to corrosion, and brushed or polished finishes, which are typically used for decorative purposes. Overall, the choice of surface finish for steel coils depends on factors such as the intended use, environmental conditions, and desired appearance, with each finish offering its unique advantages and characteristics.

- Q: How are steel coils inspected?

- Steel coils are inspected through various methods such as visual inspection, dimensional measurement, and non-destructive testing techniques. Visual inspection involves the examination of the coils for any surface defects, such as scratches, dents, or rust. Dimensional measurement ensures that the coils meet the required specifications in terms of thickness, width, and diameter. Non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, and eddy current testing are used to detect any internal defects or discontinuities in the steel coils without causing any damage to the material. These comprehensive inspection methods ensure the quality and integrity of steel coils before they are used in various industries.

- Q: How are steel coils used in the production of metal doors and windows?

- Steel coils are an essential component in the production of metal doors and windows. These coils are typically made from high-quality steel and serve as the primary raw material for manufacturing these products. The first step in utilizing steel coils is the process of uncoiling. The coils are unwound and fed into a machine known as a roll former. This machine carefully shapes the steel into the desired profile for the door or window frame. The steel is typically cut to the required length before being fed into the roll former. Once the steel has been shaped, it is then sent through a series of additional manufacturing processes. These processes may include punching holes for hardware installation, bending the steel to create specific angles or curves, and welding different sections together to form a complete frame. The steel coils provide the necessary structural integrity and durability required for these processes. Furthermore, steel coils also play a crucial role in enhancing the aesthetic appeal of metal doors and windows. They can be coated with various finishes, such as galvanized or powder-coated, to provide protection against corrosion and improve the overall appearance of the final product. These coatings not only add a layer of durability but also allow for customization to match different architectural styles and design preferences. In summary, steel coils are the foundational material used in the production of metal doors and windows. They are shaped, cut, and processed to create the necessary components for these products. Additionally, steel coils can be coated to enhance their durability and aesthetic appeal. Ultimately, these coils contribute significantly to the strength, durability, and overall quality of metal doors and windows.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality For Galvalume Steel Coil AZ150 From China

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords