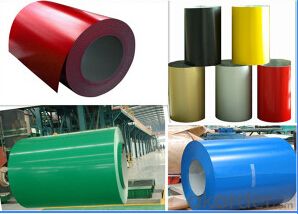

PPGI Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:Thickness: 0.125--1.3mm*600-1250mm

Type:Steel Coil

Technique:Hot Rolled

Standard:ASTM, GB, JIS

Surface Treatment:Coated

Special Use:High-strength Steel Plate

Pre-Painted Steel Coi:Width: 610/724/820/914/1000/1200/1219/1220/1250mm

Export Markets:North America, South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Trademark:SGCH

Packing:Standard Packing to Export.

Standard:0.2mm*914mm 0.3mm*1000mm

Origin: China

HS Code:721070100

Production Capacity:8000mt/Month

Product Description

Pre-painted Galvanized Steel Coil

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate,

through the surface pretreatment (degreasing, cleaning, chemical conversion

processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling.

SPECIFICATION

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: DX51D+Z, DC51D, SPCC, SGCC, SGHC, CGCC,

3.Surface Treatment Coated: Galvanized, Paint sealant, Coating passivation solution

Substrate Cold rolled, Galvanized sheet

4.Color: RAL Color card

5.Coil ID: 508/610 mm

6.Coil weight: 4-10MT

7.Paint film Front side: 10~25um

Back side: 5~10um

8.Zinc layer: 40~180g per square meter

9.Thickness: 0.125~1.3mm

10.Width: 600~1250mm

11.Length: As requirement

12.Type: Steel plate, Steel Coil, Roofing metal

13.Place of origin: Shandong CHINA(mainland)

14.Deliver time: 20-30 days after receipt of advanced t/t or L/C

Advantages

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3.Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and

autonomous regions, and have been exported to Europe, North American, the Middle East,

the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

| commodity | prepained Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.125-1.3mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z40-180g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-10 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

- Q: I'm looking for a good source as to the 'structural formula' of steel. I'm not quite sure if that's what it's actually called, but here's a link to what I'm looking for.

- That's a very good question. What you need to do is run down to your local university and sign up for a undergraduate degree in Civil Engineering and after you finish that (4 to 5 years) then you need to sign up for a masters degree in Structural Engineering (2 to 3 years). Then, get yourself a structural engineering job and in 4 years you will be able to test to become a Professional Engineer. Whew, after that you will get paid very well as a tower designer.

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery as they serve as the raw material for manufacturing various components of the machinery, such as frames, supports, and structural elements. The steel coils are processed through cutting, bending, and welding to create the necessary parts, ensuring durability and stability in the packaging machinery's construction.

- Q: How do steel coils contribute to the HVAC ductwork industry?

- Steel coils are an essential component in the HVAC ductwork industry as they are used to fabricate and shape the ducts. The coils are formed into various sizes and shapes, allowing for efficient air circulation and distribution within heating, ventilation, and air conditioning systems. These durable coils provide structural integrity to the ductwork, ensuring a reliable and long-lasting solution for HVAC installations.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- There are several factors that can affect the corrosion resistance of steel coils, including the composition of the steel, the presence of impurities, the environmental conditions, the coating or protective layer applied to the steel, and the presence of any physical damage or defects on the surface of the coils.

- Q: Cast steel welding

- I Use these for cast iron, www.yms .uk/welding-rod-small-pack/2.5mm-cast-iron-welding-rod-small-pack/1951/11612/detail.asp they are expensive when compared to welding rods for steel but i find that normal steel ones dont work on cast iron

- Q: days. Use your knowledge of the corrosion of steel and aluminum to predict how they would look different after a week exposed to rainy weather. Explain your prediction.

- I'd expect appearance of reddish dots or stains of rust on steel, while aluminium should stay virtually unchanged. Explanation: Both materials oxidize in natural environment because of atmospheric moist, but in very different ways. As for steel, oxidation begins as reddish dots of rust which grow and become stains. Oxidation then progresses in depth causing decay of material, compromising its strength and structural integrity.

- Q: How are steel coils used in the production of doors and windows?

- Steel coils are used in the production of doors and windows as they provide the raw material for manufacturing the frames and components. The coils are processed and shaped into the desired profiles, which are then used to construct the frames, sashes, and other structural elements of doors and windows. This ensures strength, durability, and stability in the final products.

- Q: (I'm not sure if steel is in fact a mineral)But I want to know if .. Last say topaz is stronger/harder then steel

- Well!! Steel is NOT a Mineral. It is an alloy!! A Mineral is a naturally occurring substance. An alloy is a mixture or metallic solid solution composed of two or more elements which is made artificially!! Also we cannot compare minerals and non minerals using strength. The only way to compare is by Hardness.. ON hardness Scale, Quartz, Topaz, Diamond, etc are HARDER than Steel

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- I believe you are asking about two vastly different processes. This is science so, if you want a specific answer, you have to ask specific questions. VERY Basically... 1) Pig iron production works by melting iron and pouring it into molds that produce ingots called pigs. 2) fraction distillation separates different substances (typically starting in liquid form) by controlled heating so, since different substances boil at different temperatures, the vapors can be captured selectively.

- Q: how do i quinch steel? i heard instead of water oil will actually make it harder... wat ways are best for wat steels? and how do i tell wat kind of steel i have?... i will be doin this with my poket knife..

- boy what a though question ! let me explain. when you rapidly cool a steel from high temperatures(depending on steel type) with water or oil or other means , it is called quenching. it depends on the steel type to say if it is better to quench it with oil or water but basically in water you will have a harder steel rather than oil. for some steels if you do this you will ruin it's properties ! you can't totally tell what kind of steel do you have until you get it analyzed with Quantometer analyzer with a pocket knife it is more like an estimation and it can't be trust able generally if you can scratch the steel with your knife it means it is not a hard steel and it might not be expensive. I hope that helps but for more information i need to know more !

Send your message to us

PPGI Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords