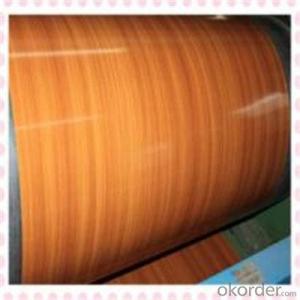

Wood Pattern Printing Galvanized PPGI Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of PPGI:

1. Environment friendly

2. Lower cost and maintenance

3. Long using time up to 10 years

4. Fast construction, time saving and labor saving

5. Easy cleaning

6. Antistatic

Festures of PPGI:

items | thickness | TYPE | Features |

Protection film | 50μm | polyethylene | Protecting from scratchs and contamination (Option) |

Finished coat | 10μm | PVDF | Protecting printed layer and enhances the appearance of the surfaces |

1μm | Ink, Polyester | Various printing patterns,3 color overprint | |

Top coat | 20μm | Polyester Fluorine | Chemical resistance, formability and patterns multiformity |

Primer coat | 5μm | Polyester | workability, corrosion resistance and adhesion to the primer coating |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

substrate | 0.2-1.2mm | GI.GL.AL | GI.GL,AL |

Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

Back coat | 5μm | Epoxy | corrosion resistance and adhesion to the substrate |

Specifications of PPGI:

1, Save your working time because of its quickly assembly

2, Saving energy ,as it uses insulated panel with heat preservation and insulation funcation.

3, Healthy and eco-friendly;

4, Sound proof

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Make your choice based on the type of music you intend to play. Nylon strings are used primarily for classical, flamenco and folk music. Steel strings are used for pop, rock, blues, country, folk, bluegrass.... Both types of guitar are tuned the same, so you *can* play any style of music on either guitar. The big difference is in the tone. Nylon strings are rich and full...if perhaps a little mellow. Steel strings are twangy and have a bite to the sound. There are differences in the construction and feel of the guitars, but that's not critical to your decision. Match the guitar to the music you intend to play. At 14 yrs old, you are certainly big enough for a full sized guitar....and I'll bet you're still growing, right? Even full sized guitars still vary in the size of the body. Try a few out to see how well they fit your reach.

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q: What minerals are mixed to make steel?

- Carbon from coal, Iron from iron ore, Calcium from limestone, Oxygen from compressed O2.

- Q: What are the different types of steel alloys used in coils?

- There are several different types of steel alloys commonly used in coils, each with its own unique properties and characteristics. Some of the most common types include: 1. Carbon Steel: This is the most basic and widely used type of steel alloy in coils. It contains a low amount of carbon and is known for its strength and durability. Carbon steel coils are often used in applications where high strength is required, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Stainless steel coils are made from an alloy of iron, chromium, and other elements. They are highly corrosion-resistant and have excellent strength and heat resistance properties. Stainless steel coils are commonly used in applications where resistance to corrosion and staining is important, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are made by coating regular carbon steel with a layer of zinc. This coating provides excellent corrosion resistance and protects the underlying steel from rusting. Galvanized steel coils are commonly used in outdoor applications, such as roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are made by adding various alloying elements, such as manganese, nickel, chromium, or molybdenum, to carbon steel. This enhances the strength, hardness, and wear resistance of the steel. Alloy steel coils are often used in applications where high strength and toughness are required, such as in the manufacturing of machinery, tools, and construction equipment. 5. Electrical Steel: Electrical steel coils are specifically designed for use in electrical equipment, such as transformers and electric motors. They have low electrical resistance and high magnetic permeability, allowing them to efficiently conduct electricity and create magnetic fields. Electrical steel coils are typically made from a silicon alloy, which improves their electrical and magnetic properties. Overall, the choice of steel alloy for coils depends on the specific requirements of the application, such as strength, corrosion resistance, electrical conductivity, or heat resistance.

- Q: Correct me if I am wrong, but steel is an alloy between iron and carbon. Does the carbon in the steel stops the iron from rusting or corroding? Also what is the difference between mild steel and stainless steel?

- Mild steel is an alloy. It is the most common form of steel. Mild steel (a so-called carbon steel) is a general term for a range of low carbon (a maximum of about 0.3%) steels that have good strength and can be bent, worked or can be welded into an endless variety of shapes for uses from vehicles (like cars and ships) to building materials. The carbon does not stop the material rusting or corroding. In addition to iron, carbon, and chromium, modern stainless steel may also contain other elements, such as nickel, niobium, molybdenum, and titanium. Nickel, molybdenum, niobium, and chromium enhance the corrosion resistance of stainless steel. It is the addition of a minimum of 12% chromium to the steel that makes it resist rust, or stain 'less' than other types of steel. The chromium in the steel combines with oxygen in the atmosphere to form a thin, invisible layer of chrome-containing oxide, called the passive film. The sizes of chromium atoms and their oxides are similar, so they pack neatly together on the surface of the metal, forming a stable layer only a few atoms thick. If the metal is cut or scratched and the passive film is disrupted, more oxide will quickly form and recover the exposed surface, protecting it from oxidative corrosion.

- Q: How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of chemical and mechanical processes. The coils are first treated with a degreasing agent to remove any oil or grease present on the surface. Then, high-pressure water jets or brushes are used to scrub away any remaining dirt or contaminants. The coils may also undergo a rinsing process to ensure all cleaning agents are removed. Additionally, some manufacturers may use acid cleaning or pickling techniques to remove scale or rust from the surface of the coils.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- harder steel has a higher carbon and chromium content

- Q: engineering sloutions related to steel fabrication

- not okorder /

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- Despite what Billy Goat says there are Crossbows that fire both Ball bearing and bolts. As for any chance of hitting your target living or paper with and degree of accuracy I doubt your chances. Especially small game. Stick to using quarrels/bolts!

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- There are different grades of Carbon Steel. A good grade is much harder than Stainless Steel and will stay sharp longer. It is also many times harder to get an edge on than Stainless Steel. I have had both and prefer the Stainless Steel because eventually the Carbon Blade does get dull, and you will wear out a Whet Stone trying to put the edge back on it. The Stainless Steel holds an edge an acceptable amount of time and is easier to sharpen when the time comes. Putting either knife through a can opener sharpener will ruin the edge and make it almost impossible to put another edge on the knife. Look closely and determine the angel of the bevel, then lay the knife bevel flat on a good whet stone and try to take a thin slice off of the stone. Turn the knife over and do the other side so you keep the edge centered on the blade. Keep turning the knife over and taking thin slices until it is sharp. Dress with a good quality sharpening steel.

Send your message to us

Wood Pattern Printing Galvanized PPGI Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords