Wood Pattern Printing Color PPGI Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

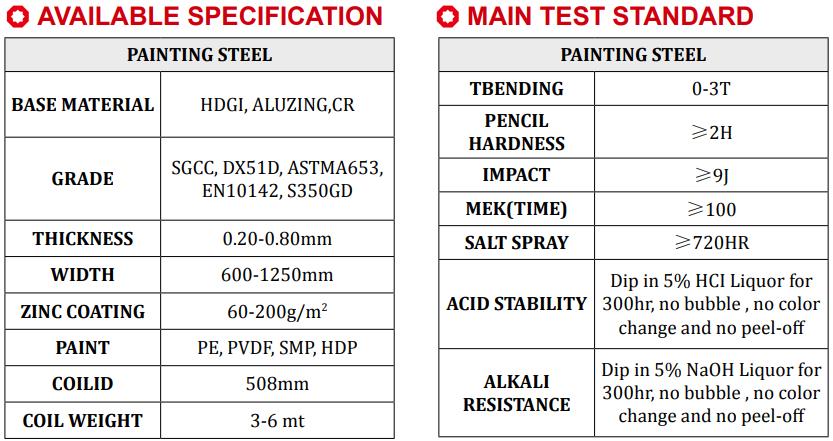

Specification

CNBM Printing steel coil is the product based on the metal steel, of which surface is finally installed of the plastic film (PVC PE) in addition to being firstly covered with the coating and printed ink in.

The coated layer of printing steel plate consists of chemical and filming layer, primer coated layer, pattern printed layer and surface coated layer.

The top and back coating shall generally be the application of the weatherproof paint, as well can be the application of the paint with special capabilities such as stain-resistance, anti-static capability, sterilizing capability, finger-print prevention and etc.

Festures of PPGI:

1. Environment friendly

2. Lower cost and maintenance

3. Long using time up to 10 years

4. Fast construction, time saving and labor saving

5. Easy cleaning

6. Antistatic

Specification

Items | Thickness | TYPE | Features |

Protection film | 50μm | polyethylene | Protecting from scratchs and contamination (Option) |

10-25μm | Polyester,SMP,HDP,PVDF | Various printing patterns,3 color overprint | |

Top coat | 10-25μm | Polyester Fluorine | Chemical resistance, formability and patterns multiformity |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

Back coat | 5-7μm | Epoxy | Corrosion resistance and adhesion to the substrate |

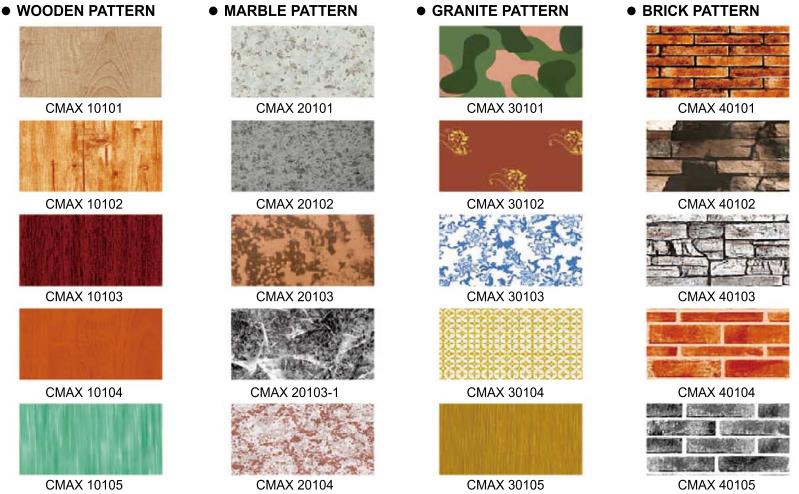

PRINT PPGI COLOR CART

APPLICATION

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: How are steel coils used in the manufacturing of agricultural sprayers?

- Steel coils are used in the manufacturing of agricultural sprayers as they are shaped and formed into the structure of the sprayer, providing strength, durability, and stability. The coils are often used as the main frame or structural components of the sprayers, ensuring that they can withstand the harsh conditions and heavy loads involved in agricultural applications.

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- It will rust but there is a product called POR that comes in clear, it will stop rust almost forever. If you don't want to go to that expense then rinse it down with acid. Ask at an automotive paint store for it.

- Q: What are the common quality issues with steel coils?

- Steel coils commonly have quality issues including surface defects, dimensional variations, mechanical property variations, coating issues, internal defects, edge issues, and coil set or camber. These issues can impact the appearance, performance, processing, and suitability of the final product. To maintain quality, manufacturers employ rigorous inspection, testing, and adherence to industry standards and specifications.

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as the core component of electromagnetic relays. When an electric current passes through the coil, it generates a magnetic field which attracts or repels a metal armature, thus opening or closing the electrical circuit. This mechanism allows electrical switches to control the flow of electricity in various applications.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they provide the necessary strength and durability required for this critical component. These coils are typically shaped and formed into various parts such as pipes, mufflers, and catalytic converters, which are then welded together to create the exhaust system. The steel coils also undergo additional processes like coating or galvanizing to enhance corrosion resistance, ensuring the longevity of the exhaust system.

- Q: I just got a set of all-clad Stainless steel frying pans, they are very nice yet they didn't come w/ instructions to care for them. I have never cooked w/ stainless steel cookware so I really don't know much about them. I was told they should have a lifetime warranty on them, but I don't want to reck them. I would appreciate any information I can get on stainless steel cookware. Thanks.

- I have stainless steel as well. i clean them like I would with any pan. however once and a while when the bottems get kind of blackened due to spillage or flames I take one of those magic eraser things to clean them up. once every 2-3 months I polish the outsides with a nice stainless steel cleaner.

- Q: How are steel coils used in the production of storage tanks and silos?

- Due to their strength and durability, steel coils are essential in the production of storage tanks and silos. Typically made from high-quality steel, these coils undergo various manufacturing techniques to achieve the desired thickness and shape. In the production process, the steel coils are initially uncoiled and then cut into specific sizes and lengths to meet the requirements of the storage tank or silo design. Bending and rolling machines are then used to shape the coils into cylindrical sections, forming the main body of the tank or silo. After achieving the desired shape, the coils are welded together to create a continuous and secure seam. This welding process ensures leak-proof tanks and silos that can withstand the pressure exerted by the stored materials. Furthermore, steel coils play a crucial role in reinforcing the structure of storage tanks and silos. They are frequently utilized to construct the roofs, bottoms, and other structural components of these storage units. The strength and resilience of steel make it ideal for supporting the weight of the stored materials and resisting external forces. Additionally, steel coils can be coated or treated with protective materials to enhance their resistance to corrosion and extend their lifespan. This is particularly important for storage tanks and silos that store corrosive substances or are exposed to harsh environmental conditions. In conclusion, steel coils are a fundamental element in the production of storage tanks and silos, providing the necessary strength, durability, and structural integrity required for these storage units.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- I find it hard to imagine the weight savings would ever be noticeable enough to justify using a less durable metal. You also need to figure the time spent replacing sprockets and it's possible a worn rear would cause early wear to the chain and then to the countershaft sprocket. You can also change your gear ratio easier by going down one tooth on the front instead. You just have to work the numbers. I've found it to be a simpler way to change the performance to meet that days needs. Keep it sunny side up!

Send your message to us

Wood Pattern Printing Color PPGI Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords