Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

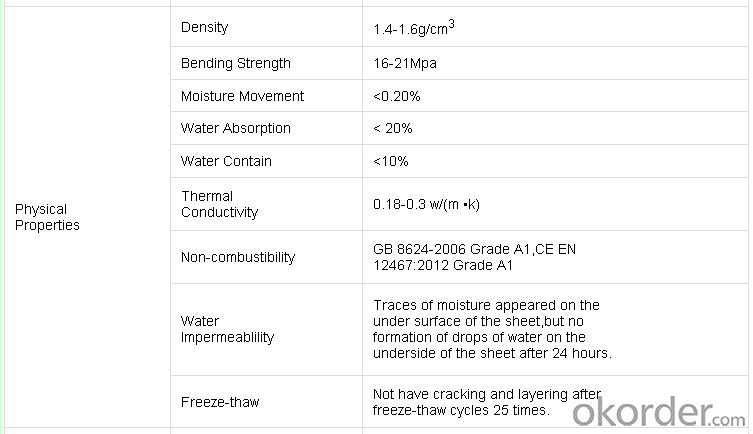

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: The tile guy that I am using has never worked with stone, so I am worried. Can you please give me some insight on some things I should know about using stone (slate) for wall tile in a shower/bath.

- You would use cement grout. If its in your house, i would consider then laquering it to make it nice and shiny and stop water sitting in cracks and creating mould.

- Q: do you have to tape cement board before tiling?

- Yes you need to tape the cement board just like drywall to avoid cracking problems later on. If you're gonna do a job, do it right.

- Q: over the bath tub is durock cement board enough by itself,or it has to be something else under durock...?

- If the tub wall is on an outside wall it should be insulated & then sealed with plastic, then durock, then the tile. For sound purposes you can insulate the other walls also.

- Q: We have an older house (1957) that has 1 thick beams as a substrate floor. Currently, there is 1/2 plywood on top of the substrate floor. We are going to rip this up so that we can apply mortar to the substrate for leveling purposes. We would put the porcelain tile directly on top of the cement board.The guy at Home Depot (a former contractor) said we can just use 1/2 cement board directly on top of the substrate floor without a layer of plywood underneath. The substrate is old, but sturdy real-wood diagonal beams that lay on top of the joists. He said they are plenty strong and we don't really need to add a plywood subfloor if we use 1/2 thick cement board.What do you think? Do you think we could get away will laying down cement board on top of the substrate floor without plywood for added strength?Thanks!

- If you have any reservations about the strength of using just the compressed cement board, why not lay that compressed cement board on top of the ply that's there now and save the hassle of ripping it up and quell those doubts. As for using a mortar for leveling purposes, why wouldn't you just use a tiling compound to rectify the levels as your tiling. After all how bad could it be, as a carpenter I'd say the guy who built the sub-floor frame couldn't have been more than a few mils out, here of there. BTW the compressed cement board will easily take the load without the ply.

- Q: i built a pair of cubed 2x4 tables,can i use cement board on top?then tile?

- With mastic cement you can stick tiles right to a wood surface providing it's flat. I used 6 floor tiles with mastic on cabinet grade plywood for our kitchen. It's lasted 17 years now. Mastic comes in plastic containers already mixed......you just trowel it on and stick your tile.

- Q: Is there anything you can add to cement which will increase insulating power?I guess asbestos is illegal and I am not even sure how much it would work, but I was wondering if there isnt something out there that will add R value to cement if you add it to the mix without substantially reducing the strength of the cement itself.

- thickness...the thicker the concrete, the better it will insulate

- Q: Wood keel cement pressure plate partition wall tiles

- The tiles are not soaked in place, the water slurry is thickened, the moisture is absorbed by the tiles too fast, the adhesion between the two is reduced, plus the shrinkage of the cement, thus causing the tiles to fall off. If you are using ceramic tile adhesive tiles, can not be completely with the adhesive, and at least 1: 1 ratio of cement and stirring use. Do not use cement sticks completely completely.

- Q: What is the difference between cement calcium silicate board and cement fiberboard

- Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, through the pulp, copy, pressure, curing from a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board. Fiber cement board length and width of the standard specifications are 1200 * 2400mm and 1220 * 2440mm, manufacturers can basically customize the length of 2000-2500mm, width of 1000-1250mm within any specifications, other specifications can be cut on this basis. Fiber cement cement board thickness of 2.5,3,3.5,4,5,6,8,9,10,12,15,18,20,24,25,30,40,60,90 mm, the strength of the manufacturers Can be customized within any thickness of 2.5-100mm. Thickness of 4mm or less known as ultra-thin plate, 4-12mm become a conventional plate, 15-30mm and above known as thick plate, 30mm or more known as the thick plate. No small press manufacturers can only produce 6-12mm ordinary cement board; general manufacturers can only produce 4-12mm conventional board, thick plate to do well, thick plate can not do; thickness 2.5-100mm can do the manufacturers The country is small. Cement fiber board is widely used, the sheet can be used for ceiling materials, perforation can be used as sound-absorbing ceiling. Conventional board can be used for wall and / or decorative materials, thick plate can be used as LOFT steel floor board, attic board, external wall insulation board, wall panels and so on.

- Q: I need to raise a bathroom floor about 3/4 inch. I have already poured a thin layer of self leveling concrete over what appeared to be some sort of concrete floor that had some uneven areas (60 year old house). I have read about how you are not supposed to put backer board on concrete because you can't secure it. My question is this: could you lay the backer board on top of the SLC, leave some small gaps between the boards, and then pour another layer of SLC on top of the backer board, thereby cementing it into place??

- I d rather see you pore a SLC to the depth you need it.. Some compounds you can pore to the depth of 1 in 1 pore and some you need to do in 2 pores. Now if you need to do a full 3/4 depth you can do a tile mud bed , but this is a little challenging for a 1 st time. If you have some good DIY skills then you can probably do it. Just going over slab requires a few different steps when doing a mud bed over slab. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I have a cement back porch/patio approx 5'x22' that I've decided to tile.I know...tile outside...touchy subject, except I got 20 inch tiles at a steal. Problem is, while doing a mock layout, I noticed that many areas on the surface are unlevel (the tile rocks). It difficult to identify every single unlevel spot so I can't patch. Any recommendations on leveling the whole thing? Someone mentioned use wonder board (thin cement board) as an overlay, but I believe you'll still have weak spots beneath.Anyone have a suggestion?

- how uneven is the slab. You can put a pretty thick layer of thinset adhesive and cover up some of the unevenness. If you put down a 1/2 inch of thinset around the bad spots will it stop the tile from rocking? the whole slab doesn't need to be even, but each tile needs to be even with the ones surrounding it

Send your message to us

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords