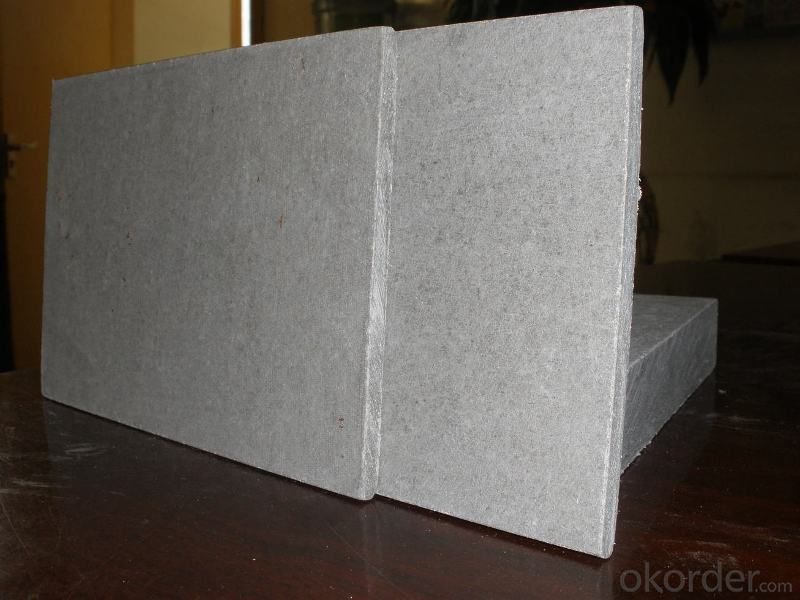

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

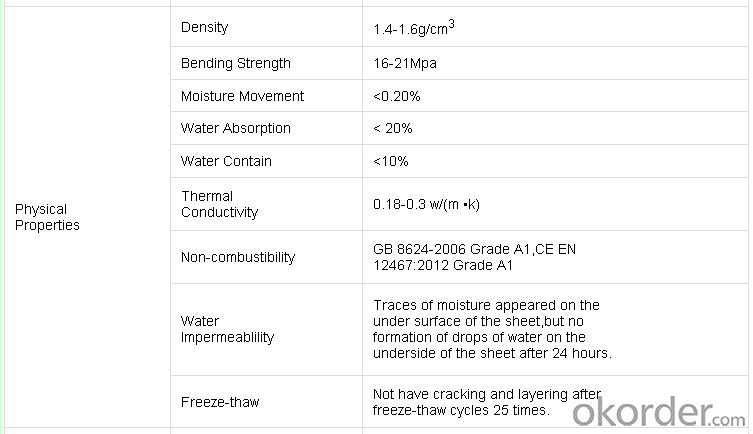

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

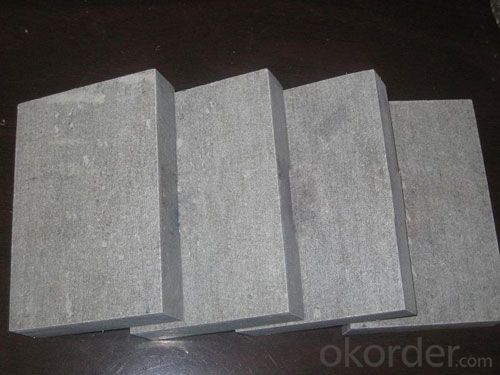

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Yesterday I started a job at a warehouse store. This store, being a warehouse has cement floors. I have a pair of walking shoes I wear with added inserts for more comfort, but after my shift yesterday, I could barely walk because of the pain in my hips, knees, foot/leg joint, and my ankles. I know that arthritis runs in my family, and that other family members have had problems when dealing with cement floors. I'm only 23, but I know arthritis can start that young (I also know my knees are total crap because of sports). So my question is, could this pain be from walking on the cement floors all day, or is this just random? I never had this happen this bad before, and have never had to be on cement floors that long either.

- Hi there: I know this the floors will just kill my feet when working on cement. You have a fine day..

- Q: i am trying to build a slideboard (he kind that speed skateres and hockey players use) by gluing a piece of particle board to a sheet of tileboard.yesterday i applied a generous amount of contact cement and put the two together immediately to dry. today they are not even sort of stuck together. what is the most likely cause?could it be because i did this in my dingy and freezing cold basement?or are you not supposed to use contact cement on particle board and or tileboard?the instructions did call for plywood and linoleum.

- Contact adhesive should be applied to both surfaces and then allowed to set for about 20 - 30 minutes (until almost touch-dry) BEFORE bringing the surfaces together. BEWARE! Once the surfaces touch they will bond instantly, with no scope for repositioning. Leave the existing cement until thoroughly dry, then re-apply as per my instructions.

- Q: Does backerboard need to be installed for new kitchen tile with cement floor?

- Backerboard is used to stiffen the wood subfloor when you lay tile. This is important so the subfloor doesn't deflect when additional weight is put onto it (thus, breaking the tiles). Since you have a cement floor, putting down a backerboard wouldn't make any sense, but the floor does need to be level. You can pick up self-leveling compound at the hardware store. It's going to be in the same aisle as grouts, tools, etc.

- Q: Hi, I have an outside breezeway that connects from my house to my garage with a roof and cement slab. I'm in the process of closing it in and making it part of my house(fully heated). I'm going to tile the floor but I'm not going to have a sub floor to insulate under it, I worry about moisture, cold floor and cracking of tiles (I live in Michigan).So my question is I'm not sure on how to go about this, I was thinking a 1/4 to 3/8 insulation rolled on the slab, then cement board and then thermostat controlled heating mat then tile, What do you think, thanks.

- I agree with William, use a rigid insulation rather than a roll insulation. It would be pretty much impervious to moisture. A roll insulation would eventually hold any moisture and get moldy and lose any r-value.

- Q: Unfortinatly i already have the tile but i was hoping i could use self leveling cement then atattch the tile to it. is this even a posabilityor should i use hardyback board and if i do how can i atattch it to the cement

- I used the self leveling concrete mixture and sure enough, it worked great. Just make sure you do your prep work to ensure excellent results.

- Q: What does the glass wire add to the cement?

- In order to increase the flexibility of cement components. After the cement is condensed, although the hardness is high, but toughness is insufficient, fragile and crackible, especially thin and thin strip type components, without glass, even the operation is a problem. The addition of glass to the microstructure of the cement can be pulled together, greatly increasing the impact resistance and bending resistance of components.

- Q: We are going to remove the vinyl flooring. It has a 1/4in sub floor over hardwood.

- Are you saying hardwood and not the ply wood sub floor? You can t go over hard wood with tile, even with a backer board.There is to much movement and expansion and contraction . Must remove this too. Now if you mean sub floor then yes it s very important that you do cement board ( 1/2) you need this total thickness in substrate to meet tile codes 1 1/4 minimum.This must be layed properly in a bed a thin set and nail well. Any other questions you can e mail me thru my avatar and check my qualifications there GL

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- In accordance with national standards: cast-in-place cement board bearing capacity is 250 kg / square meter, prefabricated board is 200 kg / square meter.

- Q: The reason I ask is b/c my boyfriend was supposed to tile the kitchen..he put down the cement board for it and assured me we bought enough clearance tile. I was unsure and measured, we don't. He has procrastinated and I don't know how to tile anyways, so I want to lay a different floor. BUT I don't want to just throw away this cement board(might learn to tile one day). Is there a type of flooring that could easily just be installed over top of the cement board?

- Make sure the disk isn't upside down, It happened to me one time and I just totally facepalmed

- Q: cost of installation per sq foot

- I used to charge 2.50$ a s/f for installing cement board. This would include the board, thin set to set it ( floors) and nails/ screws. Any questions you can e mail me through my avatar ..GL

Send your message to us

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords