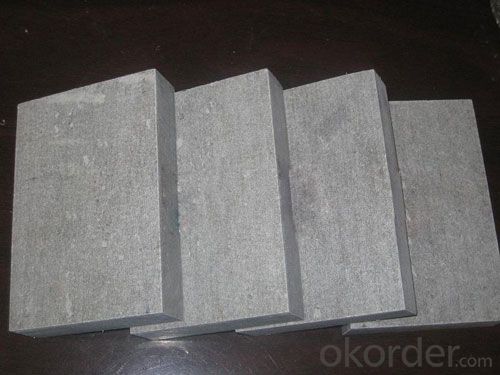

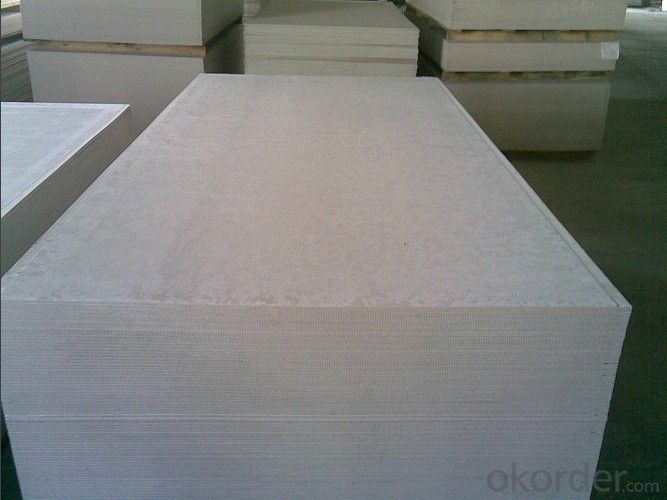

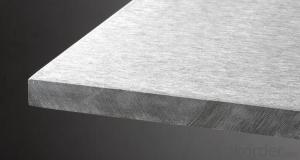

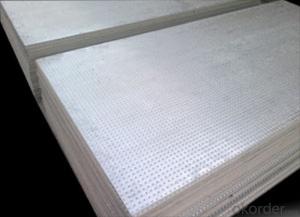

Non Asbestos Fireproof Calcium Silicate Board Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

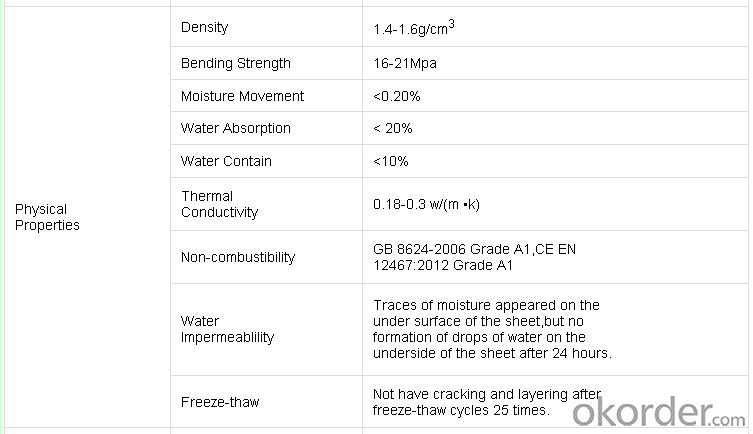

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

Images:

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- Secure the wall to the floor of the garage with something like Simpson Concrete bolts - they work like Tap-Cons, but are larger and have a greater shear strength. To avoid having the garage wall, roof, and the climbing wall collapse on top of you (that's not even good avalanche practice), anchor the top to the top plate of the garage wall. It should be anchored into a bond-beam at the top of the wall with 1/2 diameter bolts. You could also hang the wall out a little further, and secure the top to several ceiling joists or roof rafters with framing anchors. Just do not attach the climbing surface directly to the block wall; either you will pull the anchors out, or push the wall over. Look at the Simpson-Strong Tie website for bolts and framing anchors. [You must have a pretty tall garage.]

- Q: Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Home decoration to do the attic, channel structure, decoration master said just just to shop a layer of 1.8cm wooden multilayer board and then shop the floor, multi-layer board formaldehyde exceeded, want to replace the wood multilayer 5mm aluminum.

- Q: What is the kind of plate?

- Light weight: the use of the United States rock cement board for the wall, the weight of only the same thickness of the brick wall 1/15, block the wall of the 1/10, is conducive to structural seismic, and can effectively reduce the basic and structural cost.

- Q: can plywood be used instead of cement backer- board for tile?

- Im not for certain but i don't think it can be used instead of cement backer board. Plywood is very preamble and the grout may soak through? I would call a Lowe's or Home Depot and ask for the flooring dept. or lumber and ask them.

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- The primary treatment: If the concrete base, in its surface with mechanical spraying or with a broom tossing a layer of 1: 1 porridge-shaped cement mortar (20% of the water with 20 grams of water to make the surface of the solidification, hand breaking , Concrete and brick wall connection nail diamond screen (width 300mm, mesh 10mm × 10mm), nail steel wire mesh before the removal, floating ash and other impurities, steel mesh should be flat and taut.

- Q: I am buying materials for the shower pan and all the other things I need but am not sure what thickness of cement board to use for the shower walls. I am covering it with tile, if that matters. Thanks

- Use Hardibacker and seal the seams with tape and thinset. Use thinset to set the tile using 1/4 spacers. I have used and recommend that you use a tile sealer to seal the slate prior to grouting and to use epoxy grout. The grout is more difficult to install but requires no sealers which need to be redone at least once a year in a shower and is well worth the initial time and effort. Be sure to read and follow the directions on the grout bags to ensure a uniform color and good grout set. MT C

- Q: I'm looking to install siding on my home and just looking for answers to the obvious concerns....... maintenance, longevity, and energy efficiency>

- From an evergy efficency standpoint, neither has enough R value to even enter into the decision. With vinyl siding, you can add a rigid foam insulation behind the siding prior to installation that will increase the R value and some high end vinly comes with a foam insulation already laminated to the back. Hardi Board makes a pre-painted siding that has a 15 year warranty on the paint job. It doesn't ding, crack, or blow off in a strong wind. Plus, it looks like authentic wood siding (but much less expensive) However, you will pay substantially more than vinyl siding. For most people it comes down to price. When given all the facts, fiber cement is by far the superior product but if its not in your budget then vinyl siding is a respectable alternative.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q: How to do noise insulation how to deal with wall noise

- With the world light steel keel around the wall to do the skeleton, the middle of the main keel and horizontal keel, and then placed inside Sound insulation cotton also known as (glass wool), outside and then gypsum board seal.

Send your message to us

Non Asbestos Fireproof Calcium Silicate Board Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords