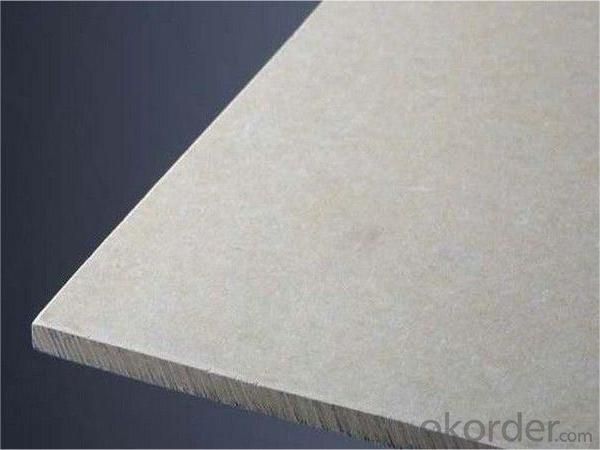

Waterproof Calcium Silicate Board Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

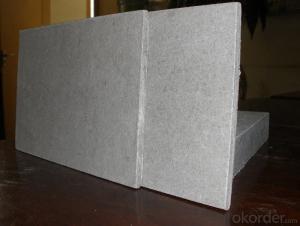

Raw materials: pure quartz powder, quicklime, calcium silicate, plant fiber, and various fine mineral fillers including dispersants and additives, are formed into a wet sheet and then processed through high temperature and high pressure autoclaving for more than 10 hours using advanced technology. This process creates a special calcium silicate board. There are no asbestos, brucite, or meerschaum in the raw materials or formulations at all.

Product Applications:

1.Industrial and residential ceilings.

2.Industrial and residential partitions.

3.Ceilings and partitions for bathrooms and wet areas.

4.Base boards for operating rooms, clean rooms, and labs.

5.Fireproof boards for air passages.

6.Furniture and accessories.

Product Advantages:

1.Excellent fire-proof

2.Excellent damp-proof

3.Durability and long service life

4.High strength

5.Stable dimensions

6.Good heat and sound insulation

7.Non-asbestos

Main Product Features:

1) 100% non-asbestos

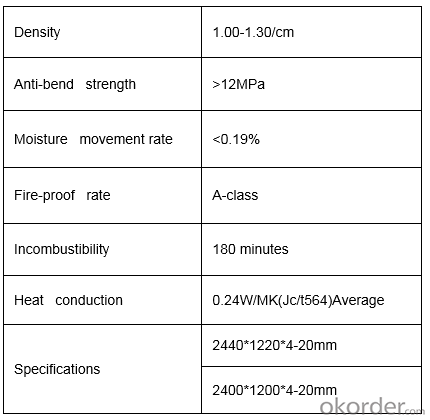

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Asbestos plate to see if the broken surface is a bunch of uneven dark gray flocculent fiber, this is the point of noncombustible. In addition, if it is a small plate ceiling, keel requirements are not large, if it is a large plate ceiling, pay attention to the steel keel will have a cat amount of money, may give you shoddy, this kind of thing to see a lot, the other can be considered with wood keel Ceiling, to do the anti-corrosion treatment of wood is good, mainly to prevent the filling putty cracking, because the steel keel on the vibration of the buffer is almost, or use elastic putty or AB glue filling, but also worry about bad, you can use Seam processing. Above are doing the words, basically with the housing with the birthday.

- Q: What is the calcium silicate board, what is the use

- Construction of ceiling ceilings and partitions, home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall.

- Q: External wall of calcium silicate board seams posted why the grid is also cracked

- First, whether the gap between the calcium silicate board (plate) is caulked with the caulking agent, because the outdoor long-term sun and rain, the reasons for thermal expansion and contraction

- Q: Silicon calcium board ceiling workers how much money a square meter

- Do silicon calcium plate ceiling minimum how much money a square to see what keel. General gypsum board the cheapest, you can use wood dragon. With just keel on your point, the general keel + board offer 55-85 per square meter.

- Q: What is calcium silicate board?

- As a new type of building plate can be used for industrial and civil construction of the partition board and ceiling panels, the surface after the water treatment can also be used as building exterior wall and composite insulation system, especially high-rise building large format wall The Because this plate has a good fire resistance, especially for the building steel structure, bearing the cover of the fire (Table 1). Although the calcium silicate board in a variety of different applications have a corresponding alternative products, but in the application of the effect and cost there is a big difference, cost-effective. As compared with the paper gypsum board, the silicon count is slightly better than the paper gypsum board in the construction, the strength, moisture, fire, life and so on are significantly better than the paper gypsum board.

- Q: Silicon calcium board is not the fire board silicon calcium board is not the fire board

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. .[1] Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- If you are a large area of the ceiling, or use strong, no need for a small area

- Q: Calcium silicate board with what saw blade saw faster

- The best way to cut stainless steel saw blades is to use high speed hacksaw blades, high speed hacksaw blades are special cut stainless steel, copper, iron and other metal. Generally used to cut pipe, so also known as cut pipe saw blade. Cutting stainless steel is recommended with M35 grades of high speed hacksaw.

- Q: Calcium silicate board can be ground?

- Yes, you can ceiling, floor, etc. are possible, calcium silicate board light, waterproof, sound absorption is very easy to use

- Q: Calcium silicate board surface putty Why crack?

- Usually in the board and board transfer place, very prone to cracking. And then the construction of such a transfer of the time, we must do anti-cracking treatment. If cracking has occurred, it will need to be shoveled along the cracks, and then fill with a dry coating, while the bandage to play a role in anti-cracking.

Send your message to us

Waterproof Calcium Silicate Board Tiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords