Waterproof Calcium Silicate Board Tiles Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

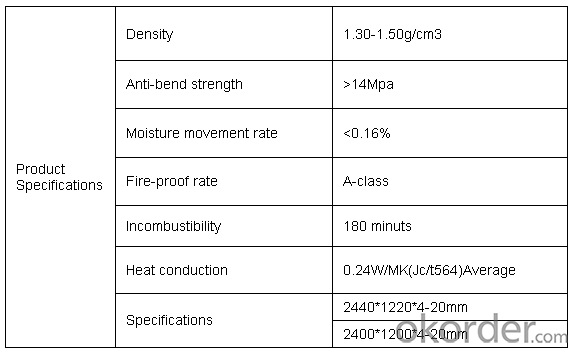

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Cement board to do the bathroom top off the skin, how to deal with

- A long time and out, paint can be directly sprayed up, putty powder

- Q: I currently have aluminum siding on my house, I want to replace it with stucco. I need to do a full tear off because behind the siding is compressed fiberboard. I will need to apply a backboard to stucco over, so the question is, should I apply cement backer board, hardiboard or plywood? Plywood would be the easiest to apply, and possibly the cheapest, but that doesn't mean it would be best. Any stucco pros with some insight?

- yea after the rip off you need to staple some felt paper (some people call it tar paper) then you neeed to use gavlanised roofing nails to nail up the wire mesh..then apply stucco...I would just nail up some 1/2 plywood..then felt paper then wire then stucco

- Q: I've removed the old cement boards and I've put new ones up on the shower walls. My tile will not go to the ceiling. I'm at the step where I need to apply thin-set and tape to all of the cement board seems. What do I do at the seem that transitions from cement board to sheet rock?

- Yes tape those seams too. Make sure you nail the dry wall there too w/ a galvanized roofing nail. You may have to do so floating w/ thin set to get it flush but it ll work fine. The thin set , when gluing to dry wall needs to be a fresh batch or just a BIT looser and wetter since dry wall will absorb the thin set fast. Not wet wet just a bit looser. Any questions you can e mail me thru my avatar and check my qualifications there GL

- Q: or add visquine on top of the plywood and then put on the backer board

- That is the proper way to do it. You need the thin set to act as a filler so there are no voids at all between the ply and the cement board. 1/4x1/4 notched trowel is the required trowel. This is according to tile installation ( both ATC and TCA tile guide line codes) and the cement board manufactures way to do it. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I am buying materials for the shower pan and all the other things I need but am not sure what thickness of cement board to use for the shower walls. I am covering it with tile, if that matters. Thanks

- Use Aquapanel Water Resistant Backing Board. It is suitable for showers and tiling. Obtainable from large DIY stores or builders' merchants eg Wickes, Jewsons Homebase etc. Size: 1200 x 900 x 12.5mm Price: around ?14 a panel

- Q: In NYS..what is the legal number of hours that a cement(concrete)driver can drive his truck & how many in between shifts?

- if he runs log books than he can drive 14 hours and he has to take 8 hr. break. my husband works with a company that has cement drivers. and once they get were they are going they could be stuck there for days. it all depends on the company also. the company can have him illegally run a few log books at once to. you can contact the labor board and they can tell you for sure.

- Q: What kind of cirrcular saw blade do I use to cut cement board?

- you can use a diamond blade to cut cement boards, gets pretty dusty though but can be pretty helpful when there are a lot of obstructions to cut around

- Q: when installing cement boards on my bathroom walls is it ok to screw them on directly?

- Directly? It is recommended to attach with screws into studs as specified for the material, so many inches apart. How would you atttach them otherwise? Do the seams with thinset mortar and fiberglass reinforcing tape.

- Q: How to do noise insulation how to deal with wall noise

- With the wooden side in the wall to make a grid, the average size of the average, and then cut the sound insulation board placed in them, each grid put away, the outside and then sealed with gypsum board.

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- Casting is in the field of mold, bar reinforcement, watering concrete and other construction procedures to do. Compared to the prefabricated system is the overall shape, good integrity, for a pipe through, or irregular shape of the floor is still very suitable, but its processes, wet operations, the site of watering, the construction period longer The The cast-in-place slab is good and the seismic capacity is strong. Generally there will be no cracks, but thinner, if not do noise treatment, will be more noisy

Send your message to us

Waterproof Calcium Silicate Board Tiles Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords