Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

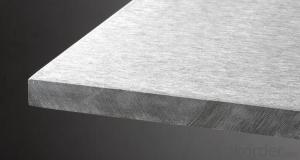

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

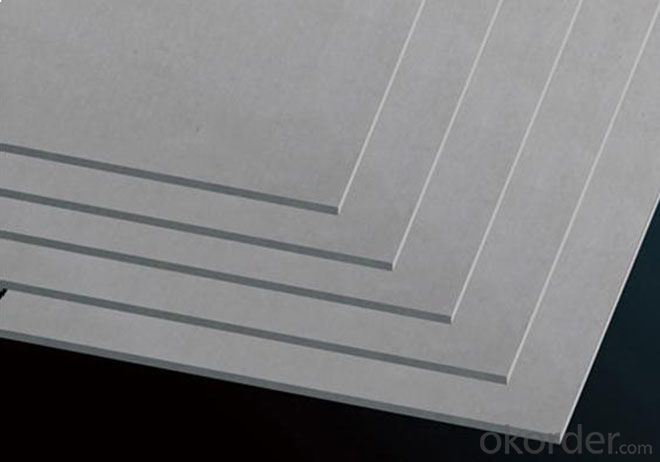

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: can plywood be used instead of cement backer- board for tile?

- Im not for certain but i don't think it can be used instead of cement backer board. Plywood is very preamble and the grout may soak through? I would call a Lowe's or Home Depot and ask for the flooring dept. or lumber and ask them.

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- External walls are generally used to deal with putty, specifically including the following steps (the above content are from the general source of paint official website related information):

- Q: What is the prc in the building?

- Prestressed reinforced concrete

- Q: I've put up my cement board walls now not sure what 2 use on it as a thin coat? I am not going 2 put tile on just want a textured cement look. Also is there a metalic type paint I can use on cement? I'm looking for options in my new shower area. There is a wax or plastic also that looks like it was a type of tile adhesive that I don't know how to get off before I stain or paint the concrete. Any suggestions on how to get it off? Can I use spray paint on the concrete in a shower area? Thank you

- If water is going to be drenching it constantly it will peel.

- Q: What are the fiberboard specifications? Fiber cement board thick

- According to industry standards JC / T412.2--2006, fiber cement board is the industry's formal name, the domestic commonly used is 1200 * 2400mm * 4 - 30mm

- Q: how do those karate guys break cement and wood pieces by jsut like one hit, why doesnt it hurtthem or break there hands and feet?dont gimme a BS answer,im lookin for an actual reasonable explanation

- The big answer is technique. And of course conditioning. If you don't have the proper technique you might end up to hurt yourself even though you are conditioned. For instance, when you condition your fist to be able to punch you work on your two big knuckles (it's where you punch) but if you don't have the right technique you might end up to punch in a circular manner that will result by punching with your little finger knuckle. At that point if you hit hard you might get a boxer fracture. Also why people don't get hurt? First: Conditioning. That way you first kill the small nerves that creates pain and then your bone gets thicker in answer of the trauma you are causing it, it's a defense mechanism. Second: simple law of physic ACTION REACTION If you go through your board or your brick the energy that you created by breaking the board is mostly lost in the air outside the board. So there is not much energy coming back to your fist. However, if you hit really hard and you don't go through, well... You get it all back... It's how I hurt my fist. But again I didn't have the proper technique... I was a bit too close so my energy wasn't at its full potential. Just a small trick in order to have maximum potential energy you should focus your power about a inch (if it's hand technique) behind the last board and about 2 inches if it's a foot technique

- Q: The roof of the cement board everywhere cracked, how to do

- At present, the better choice is the polymer waterproofing membrane: waterproof concrete and waterproof mortar two, this waterproof method is simple, easy construction, ordinary masons according to the general plaster construction method can achieve good quality requirements, and low cost , The same waterproof method under the premise of technical level, the overall cost is much lower than the flexible waterproof material for other waterproof materials 1 / 2-1 / 3, the most important thing is safe non-toxic environmental protection, but if the construction process is not good, Cement mortar is likely to crack, repair will be more trouble.

- Q: I've already got the cement board down, taking it back up would mean messing with the toilet flange, which means plumbing, and that sucks. Plywood was in pretty good condition. Thanks in advance!

- Just use a bunch of screws to hold the cement board in place. If you do this it will be just fine.

- Q: How does that work what do they have that makes them moisture resistance?

- Hydrophobic property make it moisture free.

- Q: Can anyone suggest a good way to cut small pieces (i.e. 2-4) of Hardiebacker and make it break cleanly? I can't seem to get it to break off easily unless it's bigger piece... and I was told not to use a power tool (i.e. circular saw) as it would create a ton of dust, which could be bad to breath in.

- score and snap. you may have to score it several times before you snap it. if all else fails an angle grinder with a diamond blade will cut it. wear a mask for dust protection

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords