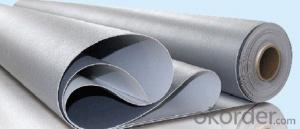

Thermoplastic Polyolefin Waterproof Membrane (TPO Waterproof Membrane)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPO Waterproof Membrane

TPO is a waterproofing sheet, consisting of thermoplastic polyolefin, and compound resin materials as the base stock, reinforced with polyester mesh fabric.

Product Applications:

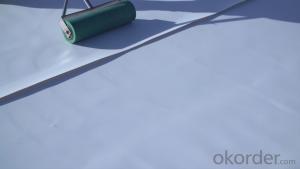

● Various roofing waterproof projects, such as industrial and civil buildings,

● Mechanically attached waterproofing system.

Product Advantages:

1. Weather resistance and durability; Excellent weld ability;

2. No any crisp agents to prevent materials brittleness;

3. Intermediate enhanced polyester mesh fabric to have high tensile strength, fatigue resistance and penetrating resistance suitable for mechanically attached roofing systems;

4. Excellent the same high and low temperature resistance as rubber materials which can keep flexible at -50° C and keep mechanical strength in high temperature;

Main Product Features:

1.. Excellent chemical resistance to acids, bases, and restaurant exhaust emissions; Dimension stability;

2.. White-based light-color and smooth surface with high reflection, energy saving and anti-dust functions;

3. Use heat welding for the seam areas to form a reliable seamless waterproof layer.

Product Specifications:

1.Thickness: 1.2mm and 1.5mm

2.Width: 1m, 2m,2.4m etc

3.Length: 20m,25m or clients’requirement.

FAQ:

Q: Can I visit your company?

A: Yes, welcome to visit our enterprise.

Q: Can I do the third party testing before loading?

A: Yes, we could accept the third party testing.

Q: Which kind of payment in your company?

A: We could accept TT, LC at sight, etc.

- Q: Can a waterproofing membrane be used for a hospital basement?

- Yes, a waterproofing membrane can be used for a hospital basement. Waterproofing membranes are commonly used in various construction projects, including hospitals, to prevent water infiltration and protect the structure from moisture-related issues such as leaks, dampness, and mold growth. The basement of a hospital is particularly susceptible to water damage due to its below-grade location, making the use of a waterproofing membrane crucial. The membrane acts as a barrier against water seepage, effectively keeping the basement dry and preventing potential damage to the building and its contents. Additionally, a waterproofing membrane can help maintain a clean and safe environment in the hospital basement by preventing the growth of mold and other harmful microorganisms that thrive in moist conditions. Overall, the use of a waterproofing membrane in a hospital basement is highly recommended to ensure the structural integrity and safety of the building.

- Q: Are waterproofing membranes resistant to oil and fuel spills?

- Yes, waterproofing membranes are designed to be resistant to oil and fuel spills. They are specially formulated to provide a barrier against these substances, preventing them from penetrating the membrane and causing damage.

- Q: Can a waterproofing membrane be used for underground stormwater detention systems?

- Yes, a waterproofing membrane can be used for underground stormwater detention systems. Waterproofing membranes are commonly used to prevent water penetration and can be effective in containing stormwater within the underground detention system.

- Q: Are waterproofing membranes resistant to diesel fuel?

- Waterproofing membranes are typically not resistant to diesel fuel. Diesel fuel is a petroleum-based product that can cause damage to many types of waterproofing materials. It can degrade the integrity of the membrane, making it less effective at preventing water penetration. Therefore, it is important to avoid exposing waterproofing membranes to diesel fuel, as it can compromise their performance and longevity. If there is a possibility of diesel fuel contact, it is recommended to use additional protective measures, such as chemical-resistant barriers or a secondary containment system, to prevent any potential damage to the waterproofing membrane.

- Q: Can a waterproofing membrane be exposed to extreme temperatures?

- In general, waterproofing membranes can handle extreme temperatures without any issue. These membranes are designed to endure a wide range of temperatures, including both high and low extremes. However, it's crucial to understand that the temperature limits and performance features may differ based on the membrane's type and brand. To ensure the membrane is suitable for the specific temperature conditions it will face, it is always recommended to consult the manufacturer's specifications and guidelines. Moreover, factors like UV exposure and thermal expansion/contraction should also be taken into account as they can impact the overall performance and lifespan of the waterproofing membrane in extreme temperature conditions.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the use of a waterproofing membrane. These membranes are created with the purpose of safeguarding surfaces against water infiltration and harm. Rubber, asphalt, or thermoplastic materials are commonly utilized to construct these membranes, which form a barrier to prevent moisture from penetrating. Whether applied to interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane is highly effective in averting issues such as leaks, mold, or structural damage caused by water seepage. It is crucial to carefully consider the unique requirements of each surface and select an appropriate waterproofing membrane for the intended use.

- Q: Can a waterproofing membrane be used for solar panel installations?

- Indeed, the utilization of a waterproofing membrane in solar panel installations is not only possible but highly recommended. It is common practice to incorporate a waterproofing membrane into the installation process in order to safeguard the roof or other surfaces beneath the solar panels from water-related harm. The primary function of a waterproofing membrane is to serve as a barrier, preventing water infiltration into the underlying structure. This, in turn, ensures the integrity and security of the solar panel installation, which is of utmost significance considering their typical placement on rooftops, where they are exposed to various weather conditions. By incorporating a waterproofing membrane, the longevity of the solar panels is prolonged, and any potential issues arising from water are effectively mitigated, thus preserving their optimal performance.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. These requirements vary depending on the local building codes and regulations in each jurisdiction. However, in general, building codes typically outline the necessary standards for materials, installation methods, and performance criteria of waterproofing membranes to ensure effective protection against water infiltration in structures. It is important to consult and adhere to these codes to ensure compliance and maintain the durability and integrity of the building.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Indeed, the resistance of a waterproofing membrane to the growth of mold and mildew stems from its specific design, which aims to establish a barrier against moisture infiltration. This impedes water seepage and the subsequent development of mold and mildew. Through the effective sealing of the area, these membranes eradicate the favorable conditions for the proliferation of mold and mildew, such as dampness and moisture. However, it is important to acknowledge that although the membrane itself exhibits resistance to mold and mildew growth, it does not guarantee absolute protection against these issues. Proper installation, regular maintenance, and ensuring adequate ventilation play pivotal roles in preventing the long-term growth of mold and mildew.

- Q: How does a waterproofing membrane handle settlement cracks?

- A waterproofing membrane is designed to handle settlement cracks by providing a flexible and seamless barrier over the surface. This membrane can stretch and move with the structure, preventing water from entering through the cracks and causing damage.

Send your message to us

Thermoplastic Polyolefin Waterproof Membrane (TPO Waterproof Membrane)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords