Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

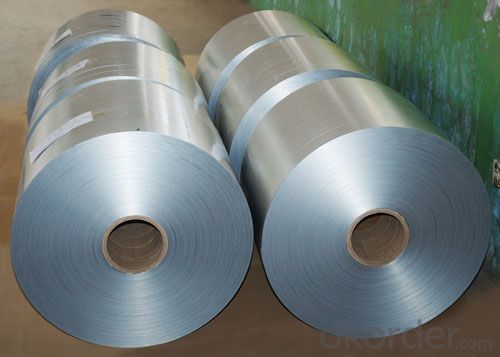

Alloy Embossed Aluminium Plate/Sheet 1050 1060

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: How are aluminum coils protected against bending and warping during storage?

- Various measures and precautions are taken to protect aluminum coils from bending and warping during storage. Firstly, the coils are typically stored horizontally to evenly distribute the weight and reduce stress on the coil, thus preventing any bending or warping that could occur if stored vertically. Additionally, protective materials such as plastic or paper are often used to wrap the coils, creating a barrier against external forces that could cause damage. These wrappings act as a cushion, preventing direct contact with hard surfaces that could result in bending or warping. Furthermore, it is standard practice to carefully and securely stack the coils, ensuring they are not overloaded or subjected to excessive pressure. This helps maintain the coils' structural integrity and prevents deformation during storage. Temperature control is also crucial in protecting aluminum coils. Extreme temperature fluctuations can cause the metal to expand or contract, potentially leading to warping. Therefore, it is important to maintain a stable storage environment to minimize any thermal stress on the coils. In conclusion, proper handling, protective wrappings, secure stacking, and temperature control all play vital roles in preventing bending and warping of aluminum coils during storage. These measures ensure the coils remain in optimal condition and are readily available for use when needed.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coils typically requires specialized tools to ensure safety and efficiency. These include cutting tools like metal snips or shears designed for aluminum, which are crucial for cutting the coils without damaging them. Additionally, a coil carrier or uncoiler is necessary for handling and unrolling the coils without causing injury or deformation. Protective gear such as gloves and safety glasses is also essential to prevent injuries from sharp edges or debris. For more precise work, a metal straightener or leveling machine may be needed to correct any warping in the aluminum coils.</p>

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum has excellent electrical conductivity and thermal properties, making it suitable for various applications in electronics, such as in transformers, inductors, and heat sinks. Its lightweight nature and corrosion resistance also make it a popular choice for electronic components.

- Q: Is it possible to utilize aluminum coils for crafting artistic installations or distinctive creations?

- <p>Yes, aluminum coils can be used to create art installations and other unique creations. Their malleability, durability, and lightweight nature make them ideal for sculptural works. Artists can bend, shape, and weld aluminum coils into various forms, offering a wide range of design possibilities. The material's reflective surface can also add visual interest, especially when used in installations that interact with light and shadow. Additionally, aluminum's resistance to corrosion makes it suitable for outdoor art pieces, ensuring longevity and low maintenance.</p>

- Q: Can aluminum coils be used for window frames?

- Certainly, window frames can indeed be made using aluminum coils. Aluminum is widely favored for window frames owing to its enduring nature, lightweight composition, and ability to resist corrosion. It is extensively employed in both residential and commercial settings. Aluminum coils can be effortlessly molded and adjusted to accommodate diverse window dimensions and designs. Additionally, aluminum frames provide exceptional thermal insulation qualities, thereby enhancing energy efficiency in structures. All in all, aluminum coils represent a dependable and pragmatic choice for constructing window frames.

- Q: This question asks for the various uses of aluminum coil within the construction industry.

- <p>Aluminum coil has several applications in construction due to its lightweight, durability, and resistance to corrosion. It is commonly used in roofing and siding materials for both residential and commercial buildings. Aluminum coil is also utilized in the manufacturing of window frames and doors due to its strength and ability to withstand harsh weather conditions. Furthermore, it is used in the production of heat exchangers and HVAC systems because of its thermal conductivity. Additionally, aluminum coil is employed in the construction of scaffolding and temporary structures due to its ease of handling and high strength-to-weight ratio. It also finds use in the fabrication of electrical conduits and cable trays because of its electrical conductivity and resistance to moisture.</p>

- Q: What are the different color options for coated aluminum coils?

- The different color options for coated aluminum coils are vast and varied. They can include classic colors such as white, black, and gray, as well as an array of vibrant and bold shades like red, blue, green, and yellow. Additionally, there are also metallic finishes available that can add a touch of elegance and sophistication to the coils. Ultimately, the color options for coated aluminum coils are limited only by the imagination and preferences of the customer.

- Q: How are aluminum coils processed for surface preparation?

- Aluminum coils undergo various surface preparation processes to ensure proper adhesion of coatings, improve corrosion resistance, and enhance overall appearance. The surface preparation steps typically include cleaning, degreasing, and etching. Firstly, the coils are cleaned to remove any dirt, dust, or other contaminants by using either mechanical or chemical methods. Mechanical cleaning involves using brushes, scrubbers, or high-pressure water spray to physically remove the surface impurities. Chemical cleaning, on the other hand, involves the use of mild alkaline or acidic cleaning agents that dissolve and remove contaminants. After cleaning, the coils are degreased to eliminate any residual oils or greases. Degreasing can be done using solvents or by employing an alkaline degreasing process. Solvent-based degreasers are applied to the coil surface, allowing them to dissolve and remove any oil or grease residues. Alkaline degreasing, on the other hand, involves immersing the coils in an alkaline solution that reacts with the grease, forming a soap that is then easily rinsed off. Once cleaned and degreased, the aluminum coils may undergo an etching process to enhance surface roughness and promote better adhesion of subsequent coatings. Etching is typically done using either chemical or electrolytic methods. Chemical etching involves immersing the coils in an acidic solution that removes a thin layer of aluminum oxide from the surface, creating a roughened surface. Electrolytic etching, on the other hand, uses an electrical current to remove the oxide layer. After surface preparation, the aluminum coils are usually rinsed with water to remove any residual cleaning or etching chemicals. The coils are then dried to ensure a clean and dry surface, ready for the application of coatings or further processing. Overall, the surface preparation of aluminum coils involves a combination of cleaning, degreasing, and etching processes to ensure a clean, smooth, and properly prepared surface for subsequent treatments.

- Q: Can aluminum coils be used in the production of automotive parts?

- Indeed, automotive parts can be produced using aluminum coils. As a lightweight and highly malleable metal, aluminum is an excellent choice for manufacturing various components in the automotive industry. Body panels, hoods, fenders, doors, and even engine parts can all be fabricated using aluminum coils. The utilization of aluminum in this sector presents several benefits, such as enhanced fuel efficiency, superior performance, and reduced vehicle weight. Furthermore, aluminum coils are easily manipulable and can be shaped into intricate forms, allowing for greater design adaptability in the manufacturing of automotive parts. In conclusion, the use of aluminum coils has become increasingly popular in recent years and is now a common practice in the production of automotive components.

Send your message to us

Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords