Syt Aluminum Sheet/Coil - Fin Stock Aluminum Foil with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Fin Stock Aluminum Foil Description:

1000 series are essentially pure aluminium with a minimum 99% aluminium content by weight and can be work hardened. Widely applied in chemical industry, scientific experiments, ect.. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Fin Stock Aluminum Foil:

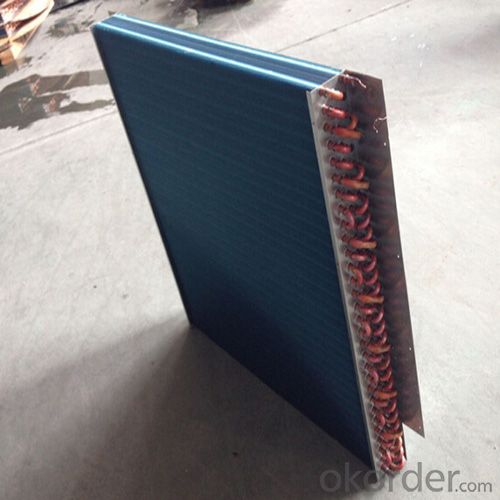

>Aluminum foil for fin stock;Heat exchange&condensator for A/C

>Alloy:1100/3003/8011-H22

>Thickness: 0.09~0.2mm

>Width:100mm~1000mm

3. Fin Stock Aluminum Foil Images:

4. Fin Stock Aluminum Foil Specification:

| Product | Alloy | Temper | Thickness mm | Width mm | Core I.D mm | Pipe OD mm |

| Aluminium Foil | 1235 | H18 26 H24 O | 0.007~0.2 | 90~1520 | 75 150 500 | 200~1700 |

| 8011 | H18 H26 H24 O | 0.007~0.2 | 90~1520 | 75 150 500 | 200~1700 | |

| 8006 | H18 H26 H24 O | 0.007~0.2 | 90~1520 | 75 150 500 | 200~1700 | |

| 1060 | H18 H26 H24 O | 0.007~0.2 | 90~1520 | 75 150 500 | 200~700 |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum coils suitable for architectural façade systems?

- Indeed, architectural façade systems can indeed make use of aluminum coils. Aluminum is a remarkably adaptable and enduring material; it can be easily molded and manipulated to suit the specific design requirements of a building's façade. It possesses a lightweight structure, is resistant to corrosion, and can endure extreme weather conditions, rendering it an optimal choice for long-lasting exterior applications. Moreover, aluminum coils can be coated with a variety of finishes, such as paint or anodizing, to heighten their aesthetic appeal and provide additional protection against fading or chipping. The pliability and versatility of aluminum coils make them an exceptional choice for architectural façade systems, enabling the creation of imaginative and distinctive designs while maintaining durability and performance.

- Q: How to sell the super hard 5083aluminum alloy and 5083 aluminum coil?

- Among the alloy which cannot endure heat treatment, 5083 aluminum alloy, a kind of high magnesium alloy, has the properties of intensity, machinability, anti-corrosion, electric-arc weldability and aesthetic after anodizing. The main element of 5083 alloy being magnesium, it is endowed with corrosion resistance, weldablility and moderate intensity, thus applicable to maritime areas such as ships, and cars, airplane weldments, metro light rail, and pressure vessel (such as liquid tank truck, refrigerated truck, refrigerated container), refrigerating equipment, television tower, drilling equipment, transport facility, missile parts, armor and so on.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: It's time for a new bike and I don't know enough about the pros and cons of aluminum vs. carbon fiber. I can get a low-end carbon bike or a high-end aluminum for about the same price, so the budget is not really a major issue. Any opinions would be appreciated.

- carbon is normally lighter but i would prefer the high end aluminum

- Q: Explain the distinction between standard and non-standard aluminum coils, focusing on their specifications and applications.

- <p>A standard aluminum coil is manufactured according to specific industry standards, such as thickness, width, and alloy composition, making it suitable for common applications like construction, automotive, and packaging. Non-standard aluminum coils, on the other hand, are tailored to meet unique customer requirements, featuring customized dimensions, alloys, or finishes that deviate from the norm. These are often used in specialized industries or for specific projects where standard coils do not meet the necessary specifications.</p>

- Q: How are aluminum coils used in the production of consumer electronics?

- Consumer electronics rely heavily on the utilization of aluminum coils for a multitude of purposes. A prevalent example is their application in the creation of heat sinks. These heat sinks are instrumental in dissipating the heat produced by electronic components like microprocessors, thus averting overheating and ensuring optimal performance. To achieve this, aluminum coils are often molded into fins or plates and subsequently affixed to these components, exploiting the exceptional thermal conductivity of aluminum. Another way aluminum coils find use in the realm of consumer electronics is through their incorporation into electromagnetic shields. The primary objective of these shields is to obstruct or redirect electromagnetic interference (EMI) generated by electronic devices. Given aluminum's exceptional electrical conductivity, it is an ideal material for the construction of these shields. Manufacturers shape the coils into diverse forms and sizes in accordance with the specific requirements of the electronic device, seamlessly integrating them into the overall design to minimize EMI. In addition, aluminum coils serve a vital purpose in the production of electrical connectors and wiring within consumer electronics. Aluminum's lightweight nature, durability, and commendable electrical conductivity make it an excellent choice for these applications. Manufacturers frequently process and shape the coils into thin, flexible strips or wires that can be effortlessly integrated into the electronic circuitry. To summarize, the indispensability of aluminum coils in the manufacturing process of consumer electronics is undeniable. Their ability to function as heat sinks for thermal management, electromagnetic shields for EMI protection, and electrical connectors and wiring for efficient electrical conductivity underscores their versatility. Coupled with their outstanding thermal and electrical properties, aluminum coils are an integral component in the production of a diverse range of consumer electronic devices.

- Q: What are the typical mechanical properties of aluminum coils?

- The mechanical properties of aluminum coils can vary depending on the specific alloy and temper of the material. However, some typical mechanical properties of aluminum coils include: 1. Tensile strength: Aluminum coils generally have a high tensile strength, which refers to the maximum amount of tensile stress a material can withstand before it breaks. This property is important for applications that require the material to withstand heavy loads or stress. 2. Yield strength: Yield strength is the amount of stress a material can withstand without permanently deforming. Aluminum coils typically have a relatively high yield strength, allowing them to maintain their shape and structural integrity under normal operating conditions. 3. Elongation: Elongation refers to the amount a material can stretch or deform before it fractures. Aluminum coils typically have a relatively high elongation, making them suitable for applications that require the material to be formed or bent without breaking. 4. Hardness: The hardness of aluminum coils can vary depending on the alloy and temper. Aluminum alloys can be heat-treated to increase their hardness, making them more suitable for applications that require wear resistance or need to withstand harsh environments. 5. Fatigue strength: Fatigue strength is the ability of a material to resist the formation and growth of cracks under cyclic loading conditions. Aluminum coils generally exhibit good fatigue strength, making them suitable for applications subjected to repeated or fluctuating loads. It is important to note that these properties can vary depending on the specific alloy, temper, and processing conditions of the aluminum coils. Therefore, it is recommended to consult the material specifications or contact the manufacturer for more accurate and detailed information on the mechanical properties of specific aluminum coils.

- Q: How are aluminum coils used in the production of aircraft components?

- Aluminum coils are used in the production of aircraft components as they can be easily formed, shaped, and joined together to create various parts such as fuselage panels, wings, and structural elements. The coils are typically processed through a series of steps including cutting, bending, and welding to fabricate these components. The lightweight and high strength properties of aluminum make it an ideal choice for aircraft applications, as it helps to reduce the overall weight of the aircraft while maintaining structural integrity.

- Q: Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

- Q: Aluminum is soft, so I have a roll coating, the material is very soft, 0.7*970, into 2100, it can be processed

- The profile: steel wire steel wire rod steel I-beam steel H steel rail profile quality profile of other profilesThe stainless steel plate, stainless steel coil, stainless steel stainless steel tube stainless steel stainless steel wire stainless steel billet stainless steel metal products and other stainless steel materials

Send your message to us

Syt Aluminum Sheet/Coil - Fin Stock Aluminum Foil with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords