Aluminum Master Casting Coil Hot Rolled/Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

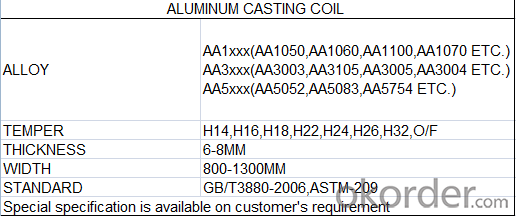

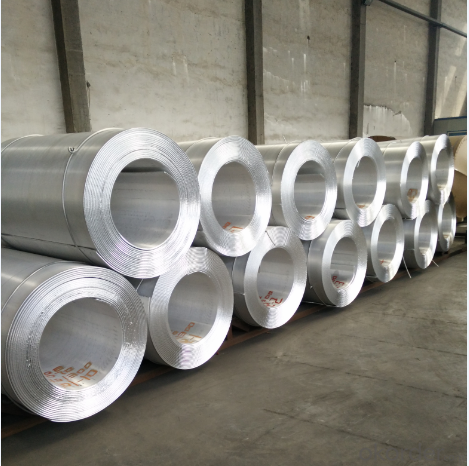

1.Structure of Aluminum Master Casting Coil Hot Rolled/Cold Rolled:

Aluminum Master Casting Coil Hot Rolled/Cold Rolled is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Casting Coil Hot Rolled/Cold Rolled:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Casting Coil Hot Rolled/Cold Rolled

4. Production Process of Aluminum Master Casting Coil Hot Rolled/Cold Rolled

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Casting Coil Hot Rolled/Cold Rolled

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: Are there any specific maintenance requirements for aluminum coils?

- Yes, there are specific maintenance requirements for aluminum coils. Aluminum coils are commonly used in HVAC systems and require regular cleaning and maintenance to ensure optimal performance and longevity. Some of the maintenance requirements for aluminum coils include: 1. Cleaning: Regular cleaning of aluminum coils is necessary to prevent the buildup of dirt, dust, and other contaminants. This can be done using a soft brush or a vacuum cleaner with a brush attachment. It is important to clean both the fins and the surface of the coils to ensure proper airflow. 2. Inspection: Regular inspection of aluminum coils is essential to identify any signs of damage or corrosion. Look for any bent fins, leaks, or signs of wear and tear. If any issues are detected, they should be addressed immediately to prevent further damage. 3. Coil Protection: Applying a protective coating to aluminum coils can help prevent corrosion and extend their lifespan. There are various coatings available in the market specifically designed for aluminum coils, which can provide an additional layer of protection against environmental factors. 4. Air Filter Maintenance: The air filters in HVAC systems play a crucial role in maintaining the cleanliness of the coils. It is important to regularly clean or replace the air filters to prevent the accumulation of dust and debris on the coils. Clogged filters can restrict airflow and reduce the efficiency of the system. 5. Regular Maintenance Schedule: Creating a regular maintenance schedule is essential to ensure that all necessary maintenance tasks are performed on time. This can include cleaning, inspection, and any other specific requirements recommended by the manufacturer. It is important to consult the manufacturer's guidelines and recommendations for specific maintenance requirements for aluminum coils, as they may vary depending on the type of system and application. Following these maintenance requirements can help ensure that aluminum coils function efficiently and have a longer lifespan.

- Q: What advantages does 0.1*100cm aluminum coil have? Is it suitable for the roof tiling? How is the anti-oxidation and anti-corrosion performance?

- 0.1 aluminum sheet has no intensity, so 0.5-1mm colored steel is often used to make roofing.

- Q: If so why does an aluminum bend or get nicked or break quickly?

- MPCheu is on the right track. Bending and getting nicked so it will break quickly are different things than strength and there are many different types of strength. Previous answers are correct regarding specific strength, say yield strength per unit mass because Al is much less dense than iron (the primary component of steel). It is also worth noting that there are many different types of steels and any one of these steels can have a very large range of mechanical properties. Same is true of aluminum alloys. The reason most airplanes are made using Al alloys is all about this specific strength and it is the same reason Al alloys are being replace by composite materials which have even higher specific strengths, densities about the same as Al but with much higher strengths. hope this helps

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- Aluminum is not biodegradable. Also making aluminum from ore requires a lot of energy. Recycling cans is easy and saves a whole lot of energy reducing green house gases. Recycling aluminum also reduces the mining required to dig up aluminum ore thereby saving the land and stopping pollution from mine run-off.

- Q: On Square-D service panels, are the main lugs rated for aluminum wire? Or do I need to use an anti-oxidant compound? What about on Milbank outdoor meter bases?

- Aluminum to Aluminum they say you do not need an inhibitor. I have still aways used it as has every electrical contractor I have worked for for 30 years. Utility companies use it on all meter bases as well. The oxidation can still be persistent so I suggest you use it and torque them to the manufactures labeling. So many people over tighten the conductors and this is a major problem because aluminum is very soft it does have a torque guideline for each conductor size as well as the lug it is attached to. Electrical Contractor ||

- Q: Are aluminum coils suitable for high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and can deform or degrade at elevated temperatures.

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: Can aluminum coils be used in the production of aluminum downspouts?

- Certainly, aluminum coils have the potential to be employed in the manufacturing process of aluminum downspouts. Normally, high-grade aluminum alloy is utilized to fabricate aluminum coils, which are subsequently transformed into thin sheets by means of rolling. These sheets can be conveniently cut and molded into diverse dimensions and forms, including downspouts. The lightweight, long-lasting, and corrosion-resistant characteristics of aluminum make it a favored option for downspouts. Moreover, aluminum coils can be effortlessly manipulated and shaped according to precise design prerequisites, rendering them appropriate for the production of aluminum downspouts.

- Q: Can aluminum coils be used for food processing equipment?

- Yes, aluminum coils can be used for food processing equipment. Aluminum is a common choice for food processing equipment due to its excellent thermal conductivity, corrosion resistance, and lightweight nature. It is widely used in the food industry for various applications such as heat exchangers, evaporators, and condensers. Aluminum coils are specifically designed to efficiently transfer heat and maintain a stable temperature, making them suitable for food processing equipment that requires precise temperature control. Additionally, aluminum is a non-toxic material, ensuring that it does not contaminate the food being processed. Therefore, aluminum coils are a reliable and safe choice for food processing equipment.

Send your message to us

Aluminum Master Casting Coil Hot Rolled/Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords