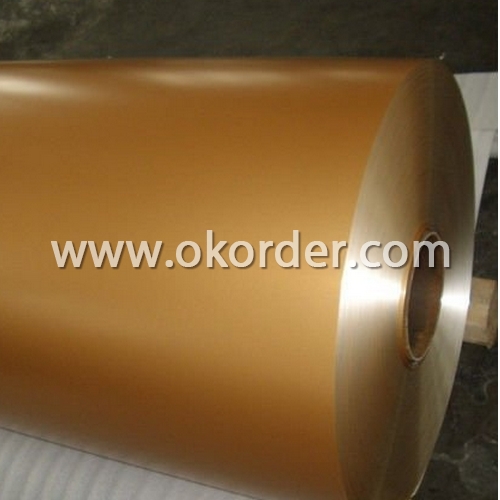

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information of anti-scratch coated aluminium coil/sheet:

Anti-scratch Coated aluminum coil is between 0.10 mm and 4.00mm in thickness with PVDF, PE. Color is according to RAL colors or customer's sample. The coated aluminum coil/sheet has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

2.Features of anti-scratch coated aluminium coil/sheet:

CNBM produces aluminum coils which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3.The main producing procedure of anti-scratch coated aluminium coil/sheet:

Rolling--Annealing--Slitting—Rinsing—Coating—Baking---Coiling

4. Specification of anti-scratch coated aluminium coil/sheet

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2200mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

coated aluminium, coated aluminiumcoil,pvdf coated aluminium panel,pe coated aluminium sheet,composite aluminium panel,roller coating aluminium sheet,

Alloy:1050/1060/1070/1100/1200/3003/3004/3104/5052/5754/5083/8011. Temper:O/H12/H14/H16/H18/H19/H22/H24/H26. Thickness:0.006-8mm. pvdf roller coating/coated aluminium coil/sheet can suit for large area house and wall decoration when finished by cut and punch further processing. Rolling coating coil for ceiling and roofing includes PVDF series/nanometer series/pearly luster series/self clean series/anti scratch series and wood grain series for different ceiling/roofing/house decorative and lamp decoration.

taking samples from the real wood and marble stone and with supreme coating technology,our wood/marble rolling will show you elegant,tridimensional and clear texture,be of easy clean,weather resistance,environment friendly high strength,which the real wood and marble can not reach. The wood/marble coils are especially suitable for project,house and indoor high pressure decoration.

- Q: Can aluminum coils be used in food processing industries?

- Yes, aluminum coils can be used in food processing industries. Aluminum is a widely used material in food processing due to its numerous advantageous properties. It is lightweight, flexible, and has excellent thermal conductivity. These qualities make aluminum coils ideal for applications such as refrigeration, heat exchangers, and ovens in the food processing industry. Additionally, aluminum is non-toxic, corrosion-resistant, and does not impart any odor or taste to the food products being processed. This makes it a safe and hygienic choice for food processing equipment. Furthermore, aluminum coils are easy to clean and maintain, which is crucial in maintaining the highest standards of cleanliness and food safety. Overall, aluminum coils are widely accepted and used in food processing industries due to their superior performance and suitability for food-related applications.

- Q: Can aluminum coils be used in the manufacturing of automotive wheels?

- Indeed, automotive wheels can incorporate aluminum coils. The lightweight and corrosion-resistant nature of aluminum makes it a favored material choice for wheel manufacturing. By shaping and molding aluminum coils, one can achieve the desired wheel design, ensuring both sturdiness and endurance, while simultaneously diminishing the vehicle's overall weight. Moreover, aluminum wheels facilitate superior heat dispersion, thereby enhancing braking capabilities. Consequently, opting for aluminum coils proves to be a fitting choice when producing automotive wheels.

- Q: I don't have a rounded baking tray at the moment and would like to replace it with aluminium foil, do you think it's suitable and that it can withheld the intensity?

- Should be fine

- Q: Are aluminum coils suitable for high-strength applications?

- In comparison to materials like steel, aluminum coils generally have a lower tensile strength, making them unsuitable for high-strength applications. Additionally, aluminum is more susceptible to deformation when exposed to heavy loads due to its lower strength-to-weight ratio. Nonetheless, there are certain aluminum alloys like the 7000 series that have been developed to increase their strength, making them suitable for industries like aerospace and automotive that prioritize lightweight properties and moderate strength. However, when it comes to applications that demand the highest level of strength, steel or other high-strength materials are typically preferred over aluminum coils.

- Q: Can aluminum coils be fabricated or formed into different shapes?

- Yes, aluminum coils can be fabricated or formed into different shapes. Aluminum is a malleable metal, which means it can be easily shaped and manipulated without cracking or breaking. Coil fabrication techniques such as bending, rolling, and stamping can be used to transform aluminum coils into various shapes and designs. These coils can then be further processed or assembled to create products with specific geometries, such as automobile parts, kitchen utensils, electrical components, or even architectural structures. The flexibility of aluminum as a material allows for a wide range of possibilities when it comes to shaping and forming it into different configurations.

- Q: What are the standard tolerance levels for aluminum coils?

- The standard tolerance levels for aluminum coils can vary depending on the specific industry and application. However, in general, the tolerance levels for aluminum coils are determined by industry standards and specifications such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). For thickness, the standard tolerance levels for aluminum coils can range from +/- 0.002 inches to +/- 0.020 inches, depending on the specific grade and thickness of the aluminum. Similarly, for width, the tolerance levels can vary from +/- 0.010 inches to +/- 0.250 inches. In terms of flatness, the standard tolerance levels for aluminum coils are typically specified as a maximum deviation from a flat plane. This can range from as low as 0.001 inches to as high as 0.020 inches, depending on the specific requirements of the application. Other factors that may influence tolerance levels include the surface finish, edge condition, and mechanical properties of the aluminum coils. It is important to consult the relevant industry standards and specifications, as well as the specific requirements of the application, to determine the appropriate tolerance levels for aluminum coils.

- Q: at what state is aluminum at room temperature?what are aluminums physical properties?what is aluminum obtained from?

- well if you took a look at the periodic table it would answer all you questions. its a metal...metal is a solid but can be a liquid when the temperatures are increased. and this page will tell u what its obtained from.

- Q: How are aluminum coils transported and delivered?

- Aluminum coils have various transportation options, including road, rail, and sea. The choice of transportation depends on factors like distance, quantity, and urgency. For short distances, road transportation is common. Special trucks with flatbed trailers or coil carriers are used to securely transport the coils. These trucks have features like adjustable cradles or coil pads to prevent shifting during transit. Longer distances often involve rail transportation. Railcars can accommodate many coils depending on their size and weight. Rail transport is cost-effective and environmentally friendly for long-haul journeys. When coils need to be transported overseas or to another continent, sea transportation is preferred. Shipping containers protect the coils from potential damage. Cargo ships have the capacity and stability for long-distance transportation. Regardless of the mode of transportation, it is vital to handle aluminum coils carefully to prevent damage. Coils are protected from excessive vibration, impact, and adverse weather conditions. Tracking systems are used to monitor the location and condition of the coils during transportation. Overall, the transportation and delivery of aluminum coils require a well-coordinated logistics network to ensure timely and efficient delivery while minimizing the risk of damage.

- Q: I would like to order 25 micron diameter 99.99% Aluminum wire required to use for making electrical connections. Only several cm are needed, so I would like to purchase a small spool. Delivery ASAP preferable (overnight or two day shipping would be best). This wire will be attached by hand using epoxy and not using a wire bonder.

- If they can't help, try asking the tech support guys at the wirebond manufacturers and the tool manufacturers. KS in the US and Shinkawa in Japan used to be the big guys. You can search for ultrasonic bond tools. You can also check with superconducting research centers; several private and public ones. Researchers might loan you materials and/or bonding support. BTW, Al critical temp is reportedly about 1.2°K, pretty tough to get that cold! U/S bond wire has 1% silicon, partly for hardness, you can probably bond pure wire though. Key is breaking up the oxide. Maybe bonding at cold temps and/or in vacuum would work. Also, I doubt epoxy would be good or superconducting at the temps. Al filled epoxy is unreliable electrical conductor due to oxide formation. Will be a bear to handle such fine wires without a bonder! Good luck!

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

1050 Aluminum Sheet Coil with Anti-Scratch Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords