Terra Bronze Aluminum Coil Embossed Treading Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Embossed Aluminium Sheets Treading Plates

Alloy: 1050, 1060, 1100, 3003, 3005, 3105, 5052, etc

Thickness: 0.2mm~20mm

Temper: H14, 18, 24, 26, 32

Width: 10mm- 1500mm

2. Application of Embossed Aluminium Sheets Treading Plates

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Aluminium Sheets Treading Plates

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

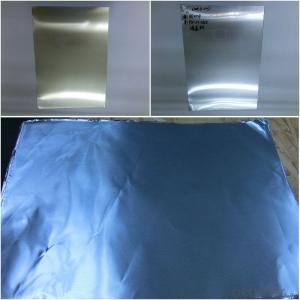

5. Image of Embossed Aluminium Sheets Treading Plates

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: Aluminum is a transition metal, woudn't the stock naming system apply to this formula?

- Aluminum oxide is best represented as Al2O3. Hope that helps.

- Q: Can aluminum coils be painted or coated after installation?

- After installation, it is indeed possible to paint or coat aluminum coils. Aluminum, being a versatile material, lends itself well to painting or coating in order to improve its aesthetics or offer extra safeguarding. Opting to paint or coat aluminum coils subsequent to installation can effectively thwart corrosion, enhance durability, and yield a personalized finish. The selection of paint or coating hinges upon the specific necessities and desired results. Prior to applying any paint or coating, it is crucial to thoroughly clean and prepare the aluminum surface to ensure strong adhesion and long-lasting results.

- Q: Are aluminum coils suitable for coil coating applications?

- Yes, aluminum coils are suitable for coil coating applications. Aluminum is widely used in coil coating due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is also highly malleable, allowing for easy shaping and forming during the coil coating process. Additionally, aluminum coils can be coated with various types of paints and coatings, providing a wide range of color and finish options. Overall, aluminum coils are a popular choice for coil coating applications due to their versatility, durability, and aesthetic appeal.

- Q: How are aluminum coils tested for surface roughness?

- Aluminum coils are tested for surface roughness using various methods to ensure they meet the required quality standards. One commonly used method is the use of a surface roughness tester or profilometer. This instrument measures the roughness of the coil surface by running a stylus or probe across the surface and recording the variations in height. The surface roughness tester provides data such as Ra (average roughness), Rz (average peak-to-valley roughness), and Rt (total height roughness). These parameters help assess the surface quality of the aluminum coil and determine if it meets the desired specifications. Additionally, visual inspection is often conducted to detect any visible defects, scratches, or irregularities on the surface. This inspection can be done manually by trained operators or with the assistance of automated systems that use cameras and image analysis algorithms to detect imperfections. Another method used to evaluate surface roughness is the use of laser scanners. These scanners emit laser beams that reflect off the surface of the aluminum coil and are then measured to determine the surface profile and roughness. Laser scanners provide high-resolution, non-contact measurements, making them highly accurate and efficient for assessing surface roughness. Overall, a combination of surface roughness testers, visual inspection, and laser scanners are commonly employed to test the surface roughness of aluminum coils, ensuring they meet the required quality standards for various applications.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: I'm asking about the aluminum tabs on soda cans. I've heard mixed things.

- Leave the tabs on the can when you bring the can to be recycled. You don't get any extra for them because they just aren't very valuable. You might want to tell the hospital that offering extra for the tabs isn't going help them and is just a waste of money.

- Q: Describe the process of rolling aluminum coil in a few sentences.

- <p>The process of rolling aluminum coil involves several key steps. Initially, aluminum ingots are heated to a specific temperature to make them pliable. Then, they are passed through a series of rolling mills where the ingots are pressed and shaped into thin sheets or coils. This process reduces the thickness and increases the length and width of the material. During rolling, the aluminum may be annealed to improve its ductility and strength. After rolling, the aluminum coil is cooled, cleaned, and inspected for quality. The final step includes coiling the rolled aluminum into manageable rolls for storage and transportation. This process is critical for producing aluminum coils used in various industries such as construction, automotive, and packaging.</p>

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Indeed, the utilization of aluminum coils is possible for the fabrication of fire-resistant structures. Being inherently fire-resistant and possessing a remarkably high melting point, aluminum emerges as an excellent substance for structures that necessitate endurance against elevated temperatures. In the realm of construction, aluminum coils are frequently employed to fulfill fire-resistant requirements, including roofs, walls, and insulation. Moreover, the lightweight and durability of aluminum further facilitate the installation and maintenance of fire-resistant structures.

- Q: How are aluminum coils used in the production of battery enclosures?

- Due to their exceptional properties, aluminum coils find wide application in the manufacturing of battery enclosures. Firstly, aluminum, being a lightweight material, is perfect for creating battery enclosures that are lightweight themselves, a crucial feature for portable devices and electric vehicles where weight reduction is of utmost importance. Moreover, aluminum coils can be easily shaped and sized to accommodate specific battery designs, giving manufacturers the ability to customize the enclosures. This flexibility in shaping also aids in optimizing space utilization and enhancing the overall efficiency of the battery system. Furthermore, aluminum exhibits high resistance to corrosion, a vital characteristic for battery enclosures that are frequently exposed to harsh chemicals and environments. This corrosion resistance ensures the longevity and dependability of the enclosure, safeguarding the battery cells from harm and guaranteeing safe operation. Additionally, aluminum possesses excellent thermal conductivity, enabling efficient dissipation of heat generated during battery charging and discharging. This is crucial in preventing overheating and maintaining the optimal temperature range for optimal battery performance. In conclusion, aluminum coils play a pivotal role in the production of battery enclosures by providing lightweight, customizable, corrosion-resistant, and thermally conductive properties. These properties contribute to the overall efficiency, safety, and durability of battery systems employed in a wide range of applications, including consumer electronics, electric vehicles, and renewable energy storage.

Send your message to us

Terra Bronze Aluminum Coil Embossed Treading Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords