5182 Aluminum Coil - Prepainted Aluminum Roofing Coil-3xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil Description:

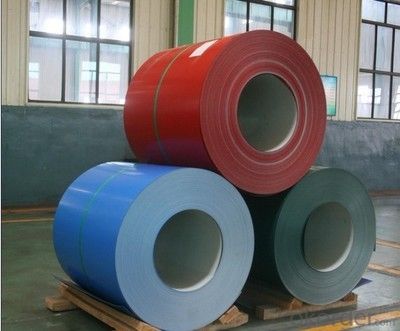

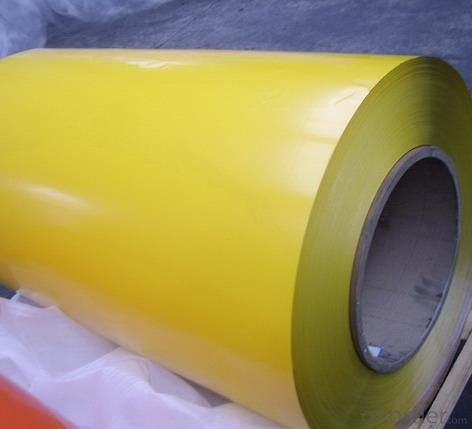

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminium Coil

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5)Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

Images of Prepainted Aluminium Coil:

Prepainted Aluminium Coil Specification:

| Prepainted Aluminum Roofing Coil, prepainted Aluminum Coil for Roofing | |||||||

| Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,8011,etc Temper: O H12 H14 H16 H18 H22 H24 H26 | ||||||

| Widths | 35mm - 2,500 mm available | ||||||

| Thickness | 0.3mm - 150 mm | ||||||

| Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm - 1270mm | ||||||

| Surface Treatment | Coated,Polished,Embossed, etc | ||||||

| Packing Detail | Wooden pallet either eye to wall or eye to sky | ||||||

| Application | 1)Building material such as metal ceiling, roofing, wall cladding panel, ACP; 2) Packaging such as Beverage Cans, Food Cans and Closures; 3) Road Commercial Vehicles and Trains; 4) Roller Shutters | ||||||

| Payment terms | TT, LC, Payment on Credit | ||||||

| MOQ | 5 metric tons | ||||||

FAQ of Prepainted Aluminium Coil :

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in automotive radiators?

- Yes, aluminum coils can be used in automotive radiators. In fact, aluminum is a popular choice for radiator construction due to its excellent heat transfer properties, lightweight nature, and corrosion resistance.

- Q: What are the different tensile strengths of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific alloy and temper of the aluminum used. Aluminum alloys commonly used for coils include 1100, 3003, 5052, and 6061. The tensile strength of these alloys can range from approximately 13,000 psi (90 MPa) for 1100 aluminum to around 45,000 psi (310 MPa) for 6061 aluminum. The temper of the aluminum also plays a significant role in determining its tensile strength. The most common temper for aluminum coils is H14, which means the material has been strain-hardened and partially annealed to achieve a balance of strength and formability. Other tempers such as H18, H24, and H32 can result in higher tensile strengths, whereas softer tempers like O (annealed) or H12 can have lower tensile strengths. It is important to note that these values are general ranges and can vary slightly depending on the specific manufacturer and production process. Additionally, factors such as thickness, width, and surface treatment of the aluminum coils can also influence their tensile strength. Therefore, it is recommended to consult the manufacturer's specifications or test the specific aluminum coil to accurately determine its tensile strength.

- Q: How are aluminum coils used in the production of architectural panels?

- The production of architectural panels heavily relies on aluminum coils as the primary material. These coils are typically made from high-quality aluminum alloy, which possesses desirable characteristics such as being lightweight, resistant to corrosion, and malleable. To begin the process of using aluminum coils for architectural panels, the raw material is uncoiled. The coils are then unwound and flattened to create flat sheets of aluminum. These sheets are later cut to the desired size and shape, based on the specific design requirements of the architectural panel. Once the aluminum sheets are prepared, various manufacturing techniques can be employed to further process them. Bending, folding, welding, and punching are some of the techniques used to achieve the desired shape and functionality of the panel. The malleability of aluminum enables precise shaping and customization, making it an ideal material for architectural panel production. Furthermore, aluminum coils can undergo coating or treatment to enhance their appearance, durability, and performance. Coatings like paint, powder coating, and anodizing can be applied to the aluminum surface to provide protection against weathering, UV radiation, and corrosion. These coatings also offer aesthetic options, allowing architects and designers to choose from a wide range of colors and finishes for their architectural panels. Architectural panels manufactured using aluminum coils offer numerous advantages. Firstly, due to the lightweight nature of aluminum, these panels are easier to handle and install, resulting in reduced labor costs and time. Additionally, aluminum's corrosion resistance ensures that architectural panels remain durable and visually appealing even in harsh weather conditions. The malleability of aluminum also allows for intricate designs and complex shapes, enabling architects to create visually striking and unique building facades. In conclusion, aluminum coils are an essential component in the production of architectural panels. Their lightweight, corrosion resistance, and malleability properties make them an ideal material for creating durable and aesthetically pleasing panels. Whether it is for high-rise buildings, residential homes, or commercial structures, aluminum coils play a crucial role in the production of architectural panels that enhance the visual appeal and functionality of modern architecture.

- Q: Are aluminum coils suitable for outdoor signage?

- Yes, aluminum coils are suitable for outdoor signage. Aluminum is a highly durable and weather-resistant material, making it perfect for outdoor applications. It is corrosion-resistant, meaning it can withstand exposure to various weather conditions such as rain, snow, and sunlight without deteriorating or rusting. Additionally, aluminum coils are lightweight and versatile, allowing for easy installation and customization. They can be easily cut, shaped, and painted to create eye-catching and long-lasting outdoor signage. Overall, aluminum coils are a popular choice for outdoor signage due to their durability, weather resistance, and aesthetic appeal.

- Q: Are there any specific regulations or standards for aluminum coil production?

- Yes, there are specific regulations and standards for aluminum coil production. These regulations and standards are set by various governing bodies and industry organizations to ensure the quality, safety, and sustainability of aluminum coil manufacturing processes. They cover aspects such as material composition, production techniques, environmental impact, and product performance. Compliance with these regulations and standards is crucial for manufacturers to maintain product integrity and meet customer expectations.

- Q: why do we use copper more than aluminum? give some characteristic of copper that makes it better then aluminum?

- more ductile, better conductor. thats about it. we use it for wires and electrical stuff. aluminum is for hard things like cans or cars.

- Q: i've been looking all over the internet for this information and i cant fin it! please help!what is aluminum's isotopic notation?what is aluminum's density at room temperature with units?what is aluminum's most common oxidation # ?aluminums e-dot diagram? symbol with valence electronschemical equation?enviornmental concers?

- Aluminum is indeed very bad for us. I avoid drinking from aluminum cans and using foil. Also, anyone using a microwave should definitely use glass dishes that are microwave safe. It is important to never use plastic wrap or plastic dishes in the microwave because carcinogens are released when the plastic is heated up. It basically cooks the toxins right into your food.

- Q: Can aluminum coils be used in the manufacturing of cans and containers?

- Yes, aluminum coils are commonly used in the manufacturing of cans and containers. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for packaging food and beverages. The coils are typically processed and shaped into desired can or container forms before being used in the manufacturing process.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing. Aluminum is a preferred material for beverage cans due to its various advantageous properties. Firstly, aluminum is lightweight, which makes it easy to transport and handle. This is particularly important for the beverage industry, where large quantities of cans are produced and distributed. Additionally, aluminum is highly malleable, allowing it to be formed into the desired shape without losing its structural integrity. This makes it ideal for can manufacturing, as it can be easily shaped into a can's cylindrical form and withstand the pressure from carbonated beverages. Moreover, aluminum is a non-toxic material, ensuring that it does not contaminate the beverages stored in the cans. It also provides a barrier against light, oxygen, and moisture, which helps to preserve the taste and quality of the beverages. Furthermore, aluminum is recyclable, making it an environmentally friendly choice for can manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable material option. Overall, the suitability of aluminum coils for beverage can manufacturing is evident due to its lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

- Q: why is aluminum used for railway lines?thanks x

- If you look at the recent trend in the materials used for railway vehicles, you may find that the mainstream material is lightweight aluminum, which is environmentally-friendly not only for bullet trains, but also for express trains. For commuter trains, stainless steel and aluminum materials are typically used, taking advantage of the merits of both metals.

Send your message to us

5182 Aluminum Coil - Prepainted Aluminum Roofing Coil-3xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords