Stucco Embossed Coated Aluminium Coil 0.10-1.50mm

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Stucco Embossed Coated Aluminium Coil

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-1.50mm |

Width: | 10mm- 1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

Special specification is available on customers' requirements.

2. Uage/Application of Stucco Embossed Coated Aluminium Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Stucco Embossed Coated Aluminium Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's payment.

4. Production Flow of Stucco Embossed Coated Aluminium Coil

Melting-Rolling- Cutting- Annealing--Packing

Stucco Embossed Coated Aluminium Coil Specifications:

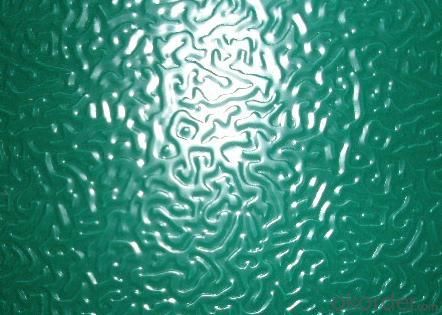

Pattern: Stucco Orange Peel pattern

Here is our products specification for your reference:

01) Alloy: A1100, A8011 etc

02) Aluminum thickness: 0.25mm~0.70mm

03) Aluminum standard width: 1200mm,1000mm, 760mm...

04) Coil's standard diameter: 1200mm

Interior diameter: 505mm hard paper core

05) Weight: 1.5-2.0/coil

06) 16coils for 1*20FT container and about 27Tons in total

06) Embossed POLYESTER color coating or Embossed mill finish

07) Outer packing: export standard, wooden plate.

- Q: What are the safety measures one should take when using aluminum coils indoors?

- <p>When using aluminum coils indoors, it's crucial to ensure proper ventilation to prevent the buildup of gases that can be harmful if inhaled in large quantities. Always follow the manufacturer's guidelines for installation and operation. Keep the coils away from flammable materials and ensure they are securely fastened to prevent tipping or falling. Regularly inspect the coils for any signs of damage or wear, and replace them if necessary. Never use aluminum coils in enclosed spaces without proper exhaust systems, and always have a fire extinguisher nearby in case of emergencies.</p>

- Q: Well, we've got the existing old school 7 layers of peeling yucky painted siding and we're trying to weigh our options. So here's my questions:1) Is it cost effective to replace Aluminum with Vinyl?2) Is Vinyl truly as costly as we keep hearing? **Home is small 1,100 sq.ft with a 2.5 car Garage**3) Is painting this existing siding a wise choice since the current paint job on it looks terrible? We just need to make it more a home, right now it's gorgeously all new and redone inside and on the outside it still resembles the day we bought it in forclosure. Aside from my green grass I busted my butt on last summer.Please advise.

- get the siding. its not that expensive and you will never have to paint again!

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is a versatile and widely used material in various industries, including chemical processing. It has excellent corrosion resistance properties, which make it suitable for handling and transporting various chemicals. Aluminum coils can be used in heat exchangers, condensers, evaporators, and other equipment in chemical processing plants. Additionally, aluminum coils offer lightweight and high thermal conductivity, which allows for efficient heat transfer and energy savings. However, it is important to consider the specific requirements and compatibility of the chemicals being processed to ensure that aluminum coils are suitable for the intended application.

- Q: I need to draw dot and cross diagrams to explain how they bond, but if the aluminium outer shell has 13 electrons and the oxygen one has 6, how do they all become happy atoms, and all have a full outer shell? please help! thank you.

- Aluminum's outer shell is 3, not 13. 13 is the total number of electrons it has. Looking a the periodic table, Oxygen's usual valance state is -2 as an ion. Aluminum's valance state is always +3. This means that oxygen gains 2 electrons to get a charge of -2 and aluminum lose 3 electrons to get a charge of +3. As for electron configuration, aluminum has 13 electrons in total. 2 e- is in the 1st sublevel. 8 e- is in the 2nd sublevel. That leaves 3 e- left but 3 is not a stable number so aluminum wants to lose those 3 e- to become stable. Oxygen has 8 electrons. 2 e- is in 1st. 6 e- is in 2nd. 6 is not a stable number so oxygen wants to gain 2 more e- to become a full set of 8. Aluminum want to lose 3, Oxygen want to gain 2. We need to balance those. 3 x 2 = 6 2 x 3 = 6 Because Aluminum's usual state is +3, we can have 2 Aluminum atoms bonding. If both lose 3 e-, they both have stable outer shell of 8 (2nd sublevel) and lose 6 e- in total. Oxygen's usual state is -2, but there are 6 e- to gain to oxygen can have 3 atoms bonding. If all 3 atoms receive 2 e- in each, then that's 6 and they're all stable, also at 8 e-. So in order to turn them into happy atom, we need 2 Aluminum and 3 Oxygen to bond together. So the chemical formula is Al2O3 (Aluminum Oxide) *** I'm not very good at explaining, I did the best I can. As for the drawing, I can't do that on the computer. It would have been a whole lot easier if I can though.

- Q: Are aluminum coils suitable for use in the automotive industry and what are their applications?

- <p>Yes, aluminum coils are widely used in the automotive industry due to their lightweight, high strength, and corrosion resistance. They are utilized in various applications including vehicle body panels, engine components, heat exchangers, and electrical wiring. Aluminum's recyclability and energy efficiency also contribute to its popularity in automotive manufacturing, helping to reduce vehicle weight and improve fuel efficiency while adhering to environmental standards.</p>

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

- Q: This question asks for the current prices of aluminum coils, which may vary based on factors such as weight, thickness, and market conditions.

- <p>The prices of aluminum coils can vary significantly depending on several factors including weight, thickness, grade, and market demand. Prices are also influenced by global economic conditions and the current state of the commodities market. As of my last update, aluminum coil prices could range from a few dollars to several hundred dollars per pound, but for the most accurate and up-to-date pricing, it's best to check with a supplier or a commodities exchange, as these prices fluctuate regularly.</p>

- Q: Can aluminum coils be used in extreme temperature conditions?

- Yes, aluminum coils can be used in extreme temperature conditions. Aluminum has a high thermal conductivity and is resistant to corrosion, making it suitable for various temperature extremes. Additionally, aluminum's low melting point allows it to withstand high temperatures without deforming or losing its structural integrity.

- Q: Can aluminum coils be used in the manufacturing of aircraft parts?

- Yes, aluminum coils can be used in the manufacturing of aircraft parts. Aluminum is a lightweight and durable material that is widely used in the aerospace industry due to its high strength-to-weight ratio and corrosion resistance. The coils can be formed and machined into various components such as fuselage skins, wings, and structural frames, making them an ideal choice for aircraft manufacturing.

- Q: What are the common quality control measures for aluminum coil manufacturing?

- Some common quality control measures for aluminum coil manufacturing include visual inspections to check for any defects or imperfections in the coils, dimensional measurements to ensure they meet the required specifications, chemical analysis to verify the composition and purity of the aluminum, mechanical testing to assess the strength and durability of the coils, and surface finish evaluations to ensure a smooth and uniform appearance. Additionally, manufacturers may implement statistical process control techniques to monitor and control the production process to consistently produce high-quality aluminum coils.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stucco Embossed Coated Aluminium Coil 0.10-1.50mm

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords