Color Coated Aluminum Coil Sheet 1060/1050 for Transformer/Electronic Components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060/1050 Aluminium Coil for Transformer/ Electronic Components

l Product Introduction

It is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O-H112

2. Thickness: 0.15-10mm

3. Width: 30-2200mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering, electronic

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

1060/1050 Aluminium Coil for Transformer/ Electronic Components | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55Packaging detail: Standard seaworthy exporting carton, Wooden | |||

l Packaging & Delivery

Packaging detail: pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: within 30 days after we get your 30% deposit or L/C

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

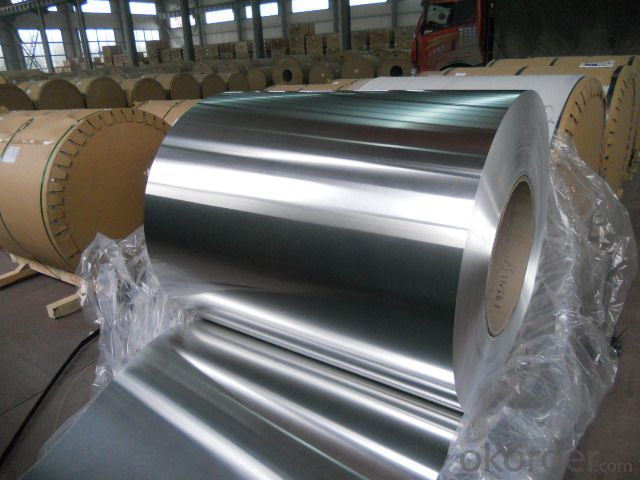

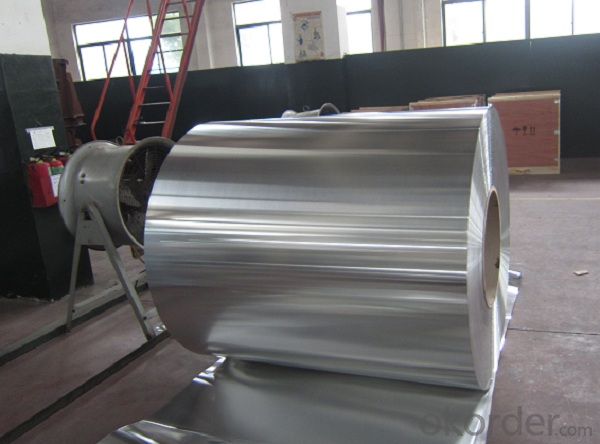

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be adjusted according to the specific requirements of a particular application. This customization is achieved through a process called aluminum coil slitting, where the original coil is cut into narrower coils of desired thickness. This allows for flexibility in meeting various needs and specifications of different industries.

- Q: How do aluminum coils contribute to energy efficiency?

- There are several ways in which aluminum coils contribute to energy efficiency. To begin with, aluminum is a highly conductive metal, enabling it to transfer heat efficiently. When utilized in HVAC systems, aluminum coils aid in the efficient transfer of heat between the air and the refrigerant, resulting in faster cooling or heating of the space. Secondly, aluminum coils possess a lightweight nature and boast a high strength-to-weight ratio. This particular characteristic makes them easier to handle and install, ultimately reducing the overall weight of the HVAC system. The reduced weight not only enhances transportation and installation efficiency but also lessens the burden on the building structure. Moreover, aluminum coils exhibit durability and resistance to corrosion. This longevity ensures the smooth operation of the HVAC system for an extended period, thereby minimizing the need for frequent repairs or replacements. Consequently, less energy is wasted on maintenance or component replacements, resulting in improved energy efficiency. Additionally, aluminum is a recyclable material, and the utilization of aluminum coils in HVAC systems promotes sustainability. The recycling process for aluminum requires significantly less energy compared to the production of new aluminum, thereby reducing the overall carbon footprint and energy consumption. Lastly, aluminum coils are frequently manufactured with enhanced fin designs and advanced technology, such as microchannel coils. These advancements increase the surface area of the coil, thereby enhancing heat transfer efficiency and reducing the energy required for cooling or heating. In conclusion, aluminum coils contribute to energy efficiency by facilitating efficient heat transfer, reducing system weight, promoting durability, supporting sustainability through recycling, and incorporating advanced technology to enhance heat exchange.

- Q: What are the pros and cons of utilizing aluminum coils in storage applications?

- <p>Aluminum coils offer several advantages for storage, including high durability, corrosion resistance, and lightweight properties which make them easy to handle. They are also recyclable and have good thermal conductivity, which can be beneficial in temperature-controlled environments. However, there are downsides such as higher initial costs compared to some other materials and potential for denting or damage if not properly handled. Additionally, while aluminum is generally non-magnetic, it can be attracted to strong magnets, which might be a consideration in certain storage scenarios.</p>

- Q: What specific conditions or considerations need to be taken into account when utilizing aluminum coils in high-temperature settings?

- <p>When using aluminum coils in high-temperature environments, it's crucial to consider the material's melting point, which is around 660掳C (1220掳F). Ensure that the operating temperature does not exceed this threshold to avoid deformation or failure. Additionally, aluminum's strength and conductivity can be affected by high temperatures, so it's important to account for potential changes in performance. Protective coatings or treatments may be necessary to prevent oxidation and maintain the coil's integrity. Always consult material specifications and consult with material science experts to determine the suitability of aluminum coils for specific high-temperature applications.</p>

- Q: Can aluminum coils be used in vacuum applications?

- Indeed, aluminum coils are capable of being employed in vacuum applications. Aluminum, being a frequently utilized substance in vacuum systems, possesses exceptional attributes including low outgassing, high thermal conductivity, and commendable corrosion resistance. Consequently, these qualities render aluminum coils suitable for a diverse array of vacuum applications, encompassing, but not restricted to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. Nevertheless, it is crucial to acknowledge that aluminum may react with particular gases or chemicals. Hence, it is imperative to carefully evaluate the specific necessities and compatibility of the vacuum application prior to employing aluminum coils.

- Q: Can aluminum coils be used in solar panel applications?

- Indeed, solar panel applications can make use of aluminum coils. Aluminum, a lightweight and robust substance, finds widespread use across diverse industries, including the solar panel industry. The base material for solar panels often consists of aluminum coils owing to their corrosion resistance, exceptional thermal conductivity, and excellent electrical conductivity. These attributes render aluminum coils ideal for efficiently transmitting heat and electricity within solar panels, thereby guaranteeing optimal performance and efficiency. Additionally, aluminum stands as a highly sustainable material, as it can be readily recycled, making it an environmentally conscious option for solar panel applications.

- Q: Are aluminum coils resistant to chemical exposure?

- Aluminum coils are generally known to be highly resistant to chemical exposure. Aluminum itself has excellent corrosion resistance properties, making it suitable for various applications where it may come into contact with chemicals. The oxide layer that naturally forms on the surface of aluminum coils acts as a protective barrier, preventing further corrosion and degradation when exposed to many chemicals. However, it is essential to note that the resistance of aluminum coils to chemical exposure may vary depending on the specific type and concentration of the chemical involved. Some aggressive chemicals or strong acids may still cause damage or corrosion over time. Therefore, it is always advisable to consult with experts or refer to specific chemical compatibility charts to determine the compatibility of aluminum coils with particular chemicals or environments.

- Q: What are the insulation options available for aluminum coils?

- There are various insulation options available for aluminum coils, including fiberglass insulation, foam insulation, and elastomeric insulation. These insulation materials help to improve the energy efficiency of the coils and prevent condensation or heat loss.

- Q: What are the storage life and shelf life of aluminum coils?

- The storage life and shelf life of aluminum coils can vary depending on various factors such as the storage conditions and the specific type of aluminum alloy used. Generally, aluminum coils have a relatively long storage life and shelf life. In terms of storage life, aluminum coils can be stored for an extended period of time without significant degradation in their quality or performance. However, it is important to store them in a dry and well-ventilated area to prevent corrosion. Moisture can cause oxidation and corrosion, which can affect the integrity and durability of the aluminum coils. As for the shelf life, aluminum coils can remain in good condition and retain their functional properties for an extended period of time when stored properly. The exact shelf life will depend on the specific application and the intended use of the aluminum coils. To ensure the longevity of aluminum coils, it is recommended to follow the manufacturer's guidelines for storage and handling. Additionally, regular inspections and maintenance can help identify any signs of corrosion or damage and take appropriate measures to prevent further deterioration.

- Q: Can aluminum coils be used in automotive manufacturing?

- Automotive manufacturing can indeed utilize aluminum coils. Aluminum, a versatile and lightweight substance, presents several advantages within the automotive sector. Frequently employed for fabricating components such as body panels, engine blocks, wheels, and heat exchangers, aluminum's incorporation in automotive manufacturing enhances fuel efficiency by reducing vehicle weight and subsequently minimizing energy consumption. Furthermore, aluminum boasts exceptional resistance to corrosion, rendering it appropriate for deployment in diverse weather conditions. In conclusion, the extensive benefits associated with the utilization of aluminum coils in automotive manufacturing have led to its widespread adoption by numerous car manufacturers.

Send your message to us

Color Coated Aluminum Coil Sheet 1060/1050 for Transformer/Electronic Components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords