020 Aluminum Coil for Casting to Thinner Coils - CC Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CC Aluminum Coil for Casting to Thinner Coils

1.Structure of CC Aluminum Coil for Casting to Thinner Coils

CC Aluminum Coil for Casting to Thinner Coils is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of CC Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the CC Aluminum Coil for Casting to Thinner Coils

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

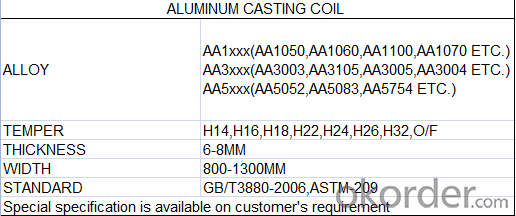

3. CC Aluminum Coil for Casting to Thinner Coils

4. Production Process of CC Aluminum Coil for Casting to Thinner Coils

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of CC Aluminum Coil for Casting to Thinner Coils

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum is a lightweight and durable material that offers several advantages for suspension components. It has a high strength-to-weight ratio, which means that it can handle heavy loads without adding unnecessary weight to the vehicle. This can result in improved fuel efficiency and overall performance. Additionally, aluminum is resistant to corrosion, which is especially important for automotive suspension systems that are exposed to harsh weather conditions and road debris. By using aluminum coils, manufacturers can ensure that the suspension components will last longer and require less maintenance. Furthermore, aluminum coils have the ability to absorb and dissipate heat more efficiently than other materials, such as steel. This can help prevent overheating and reduce the risk of suspension failure, particularly during intense driving conditions or off-road use. However, it is worth noting that the use of aluminum coils in automotive suspension systems may come with certain trade-offs. While aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must carefully design and engineer the suspension system to ensure it can withstand the necessary loads and provide adequate support and stability for the vehicle. In summary, aluminum coils can indeed be used in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. However, it is crucial for manufacturers to consider the specific requirements and trade-offs associated with using aluminum in suspension components to ensure optimal performance and safety.

- Q: How much is the 25mm aluminum coil at current market?

- You must mean 25-wide aluminum coil. The price consists of the aluminum ingot price and processing charges. For example, if the processing price is 4500 yuan, it is relatively cheap. 25mm-wide aluminum coil is very narrow, so it will be much complicated to strip.

- Q: why is aluminum oxide used more frequently than silicon carbide as an abrasive?What r the different types of tool feed mechanism in USM process.

- Aluminum oxide is tougher and therefore better suited to grinding steel, and a lot of grinding is done on steel. Silicon carbide is harder, but quite brittle, it tends to break into sharp shapes which is an advantage for nonferrous and nonmetallic workpieces, but the lack of toughness makes it specialized abrasive and therefore it is used less than aluminum oxide.

- Q: How do aluminum coils contribute to the corrosion resistance of products?

- Aluminum coils contribute to the corrosion resistance of products in several ways. Firstly, aluminum itself is a highly corrosion-resistant material due to its natural oxide layer that forms on its surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing further oxidation and corrosion. When aluminum is formed into coils, it offers additional advantages for corrosion resistance. The coil form allows for a more uniform distribution of the material, ensuring that the protective oxide layer covers the entire surface area of the product. This helps to prevent localized corrosion and ensures a more consistent level of corrosion resistance across the entire product. Moreover, aluminum coils can also be coated with various protective coatings or treatments to enhance their corrosion resistance further. These coatings can provide an additional layer of protection against environmental factors such as moisture, chemicals, and UV radiation, which can accelerate corrosion. Additionally, aluminum coils are often used in combination with other materials in products, such as galvanized steel or stainless steel. These combinations, known as bimetallic or trimetallic products, take advantage of the different properties of each material to enhance corrosion resistance. For example, the aluminum layer can act as a sacrificial anode, corroding preferentially to protect the underlying material from corrosion. In summary, aluminum coils contribute to the corrosion resistance of products due to the inherent corrosion resistance of aluminum, the uniform distribution of the material in coil form, the possibility of applying protective coatings, and the use of bimetallic or trimetallic combinations. These factors help to ensure that products made with aluminum coils have a longer lifespan and are better protected against corrosion in various environments.

- Q: What is an aluminum coil?

- Aluminum coils, which are wound into a coil shape, consist of a continuous strip or sheet of aluminum. They possess properties that make them highly sought-after in various industries, including their lightweight nature, resistance to corrosion, and malleability. The production of these coils involves a method known as continuous casting and rolling, wherein molten aluminum is poured into a caster and subsequently rolled by large metal rollers to achieve the desired thickness and shape. The utilization of aluminum coils is widespread in the fabrication of automotive components, construction materials, electrical apparatus, and packaging products. Depending on the specific application demands, these coils can undergo further processing to take on different forms, such as sheets, plates, or foils.

- Q: Are aluminum coils suitable for use in heating applications?

- <p>Yes, aluminum coils can be used for heating. They are known for their excellent thermal conductivity, which allows for efficient heat transfer. Aluminum's lightweight nature and resistance to corrosion make it a popular choice in various heating applications, such as in electric heating elements, heat exchangers, and cookware. However, it's important to note that aluminum's low melting point means it's not suitable for high-temperature applications and should be used within safe temperature limits to prevent melting or damage.</p>

- Q: What is the typical fatigue strength of aluminum coils?

- The typical fatigue strength of aluminum coils can vary depending on various factors such as the alloy composition, heat treatment, manufacturing process, and the specific application. However, aluminum is generally known for its relatively low fatigue strength compared to other metals, such as steel. Aluminum coils typically exhibit a fatigue strength that ranges between 30% to 50% of their ultimate tensile strength (UTS). This means that the fatigue limit or endurance limit of aluminum coils is usually below half of their maximum strength. It is important to note that aluminum's fatigue strength can also be influenced by other factors, including the presence of surface defects, stress concentrations, and environmental conditions such as temperature and humidity. These factors can further reduce the fatigue strength of aluminum coils. Therefore, when designing and using aluminum coils in applications where fatigue is a concern, it is crucial to consider the specific alloy and processing conditions, as well as implementing appropriate design practices and maintenance procedures to mitigate the risk of fatigue failure.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are highly suitable for food and beverage packaging. Aluminum is a safe and durable material that helps protect the quality and freshness of food and beverages. It is non-toxic, corrosion-resistant, and provides an effective barrier against moisture, oxygen, and light. Additionally, aluminum coils are lightweight, easily moldable, and can be easily shaped into various packaging formats, making it a popular choice for the food and beverage industry.

- Q: What are the typical thickness tolerances for aluminum coils?

- The typical thickness tolerances for aluminum coils can vary depending on the specific manufacturing standards and requirements of the industry. However, in general, the thickness tolerances for aluminum coils range from +/- 0.001 to 0.005 inches. These tolerances ensure that the thickness of the aluminum coils remains within acceptable limits to meet the desired specifications and applications. It is important to note that the specific tolerances may differ based on the intended use of the aluminum coils, such as for architectural, automotive, or aerospace purposes.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

020 Aluminum Coil for Casting to Thinner Coils - CC Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords