Grey Bronze Aluminum Coil - Prices of Color Coated Aluminum Sheet Coil for 1050 1060

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The Specification of Coated Aluminium Foil

1)Coil width:upon request,max up to 1550mm

2)Coil thickness:0.02-3.0mm

3)Internal diameter: 150mm, 405mm, 505mm

4)Coil weight: 1.5-4MT/coil

5)Coating: PE & PVDF color paiting

coated emboss aluminum coil/metal roofing

Aluminum Temper and Grade

Alloys: 1100, 1050, 1100, 3003, 3105, 8011 in a range of standard Temper: O-H112

Widths:Max up to 1600mm

Thickness:0.02-3.0mm

Coating:PE or PVDF

Color:AS per the RAL

Weight :1.5-4MT/Coil as per your request

Packing Detail:Wooden pallet either eye to side or eye to sky

Application:Building material such as metal ceiling, roofing, wall cladding panel; Automobiles, etc.

PVDF Coated:

Coated Aluminum Coil features with super durability and weather resistance,and better properties to anti-acid,anti-alkali,keeping more than 15 years without fading in using as external wall cladding.

The Main Features of Aluminium Coated Coil:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

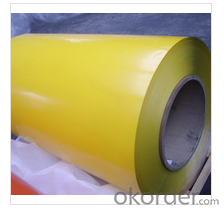

The Images of Aluminium Coated Coil:

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q: What is the maximum coil weight for aluminum coils?

- The maximum coil weight for aluminum coils can vary depending on the specific grade and thickness of the aluminum being used. However, in general, aluminum coils can typically range from a few hundred pounds to several thousand pounds in weight.

- Q: Can aluminum coils be used in food processing or packaging applications?

- Aluminum coils have proven to be highly effective in food processing and packaging. The food industry extensively utilizes aluminum due to its remarkable qualities such as resistance to corrosion, lightweight nature, and exceptional heat conductivity. This versatile material is commonly employed in food wrapping, the creation of food containers, and in the form of coils for various food processing needs. When it comes to packaging perishable food items like meat, dairy products, and beverages, aluminum coils are frequently employed. These coils can be effortlessly molded into diverse shapes and sizes to meet specific packaging requirements. The outstanding barrier properties of aluminum effectively shield the food from moisture, oxygen, and light, thereby ensuring extended shelf life and preserving food quality. In food processing, aluminum coils find application in a wide range of equipment including heat exchangers, evaporators, condensers, and refrigeration systems. The remarkable thermal conductivity of aluminum enables efficient heat transfer, making it suitable for tasks that necessitate precise temperature control. Furthermore, aluminum is completely non-toxic and does not react with food, making it an exceptionally safe and hygienic choice for food processing and packaging. Additionally, its recyclability renders it an environmentally friendly option. Overall, the widespread acceptance and utilization of aluminum coils in food processing and packaging is attributed to their versatility, durability, and ability to maintain the quality and safety of food products.

- Q: To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- just put them on

- Q: What is the lifespan of aluminum coils?

- The lifespan of aluminum coils can vary depending on various factors such as the quality of the aluminum, the manufacturing process, the environmental conditions they are exposed to, and the maintenance provided. However, on average, aluminum coils can last anywhere from 15 to 30 years. With proper care and regular maintenance, including cleaning and inspection, aluminum coils can potentially have an extended lifespan. It is important to note that regular maintenance and servicing by professionals can help identify any issues early on, allowing for timely repairs or replacements, ultimately prolonging the lifespan of aluminum coils.

- Q: How are aluminum coils tested for strength and durability?

- Strength and durability of aluminum coils are tested thoroughly using multiple methods. One of these methods is tensile testing, which determines the maximum stress a coil can endure before breaking or deforming. This test assesses the overall strength and elasticity of the aluminum. Another crucial test is the hardness test, which measures the aluminum coil's resistance to indentation or scratching. It helps determine the material's durability and ability to resist wear. Moreover, fatigue testing is commonly performed on aluminum coils by repeatedly subjecting them to cyclic loading and unloading. This test simulates real-life conditions and evaluates the coil's ability to withstand repeated stress without failing. Additionally, corrosion resistance plays a vital role in determining the durability of aluminum coils. Therefore, various corrosion tests, including salt spray testing, are conducted to evaluate the coil's resistance to environmental factors that could cause corrosion or degradation over time. In certain cases, non-destructive testing methods like ultrasonic testing or eddy current testing are utilized to detect any internal defects or inconsistencies within the coil that may impact its strength and durability. Overall, a combination of mechanical, physical, and chemical tests are carried out on aluminum coils to ensure they meet the required standards for strength and durability. These tests instill confidence in manufacturers and consumers regarding the quality and reliability of aluminum coils for various applications.

- Q: How do aluminum coils contribute to improved building aesthetics?

- Improved building aesthetics can be achieved through the use of aluminum coils in several ways. To begin with, sleek and modern exterior finishes can be created for buildings using aluminum coils. Various finishes, such as brushed, anodized, or painted, can be applied to the coils, providing a wide range of design possibilities. Architects and designers can thus achieve their desired aesthetic vision for the building with the help of this versatility in finishes. Furthermore, aluminum coils offer the advantage of being easily shaped and formed into different profiles, resulting in a unique and customized look for buildings. By bending, cutting, or perforating the coils, intricate patterns or architectural details can be created, enhancing the overall aesthetics of the structure. This flexibility in shaping allows for the creation of visually appealing designs that can make a building stand out. Moreover, aluminum coils possess the qualities of being lightweight yet durable, making them an ideal choice for cladding systems. Using aluminum coils as exterior cladding can give buildings a modern and clean appearance. The lightweight nature of the coils also makes installation easier and more cost-effective, ultimately contributing to improved building aesthetics. Additionally, the use of aluminum coils aligns with sustainable building practices and environmentally friendly designs. Aluminum is a highly recyclable material, and buildings that incorporate aluminum coils can be seen as more visually appealing due to their eco-friendly attributes. This reflects the values of the project and its occupants. In conclusion, aluminum coils contribute to improved building aesthetics through their wide range of finishes, their ability to be shaped and customized, their lightweight and durable nature for cladding, and their promotion of sustainable design practices.

- Q: What are the methods to prevent rust formation on steel coils during storage and transportation?

- <p>To prevent rust on steel coils during storage and transportation, follow these steps: 1. Keep the coils dry and avoid exposure to moisture. 2. Use rust inhibitors or anti-corrosion coatings on the coils. 3. Store the coils in a clean, dry, and well-ventilated area. 4. Use protective wrapping materials like plastic film or corrosion-resistant paper. 5. Ensure proper stacking and avoid direct contact between coils. 6. Use rust-resistant materials for transportation containers. 7. Regularly inspect the coils for signs of rust and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rust formation on steel coils.</p>

- Q: Inquiry about the feasibility of using a laser for cutting aluminum coils.

- <p>Yes, you can use a laser to cut aluminum coils. Laser cutting is a versatile process that can be used on a variety of materials, including aluminum. However, it's important to note that the type of laser and the specific settings should be appropriate for aluminum. Fiber lasers or CO2 lasers are commonly used for metal cutting, including aluminum. The process requires careful control of the laser's power, speed, and focus to achieve clean and precise cuts. Additionally, because aluminum is a reflective metal, special considerations such as the use of a protective cover gas and proper nozzle management are necessary to prevent damage to the laser equipment and to ensure the quality of the cut.</p>

- Q: What is the reflectivity of aluminum coils?

- The reflectivity of aluminum coils is typically high, as aluminum is known for its excellent reflective properties.

- Q: What is the role of aluminum coils in the construction of aircraft?

- The role of aluminum coils in the construction of aircraft is primarily to provide lightweight and strong structural components. Aluminum coils are used in various parts of an aircraft, such as the fuselage, wings, and other structural elements. The use of aluminum coils allows for better fuel efficiency, reduces overall weight, and provides durability and corrosion resistance, making it a crucial material in modern aircraft construction.

Send your message to us

Grey Bronze Aluminum Coil - Prices of Color Coated Aluminum Sheet Coil for 1050 1060

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords