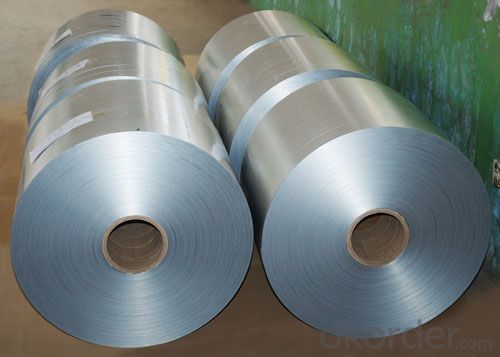

Mill Finish Aluminum Sheet Coil - Alloy 1050, 1060, 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminum Sheet And Plate Alloy 1050 1060 1100

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: How do aluminum coils contribute to energy-efficient lighting installations?

- Aluminum coils play a significant role in enhancing the energy efficiency of lighting installations. Firstly, aluminum is a highly conductive material that efficiently transfers heat away from the lighting system. This prevents the accumulation of heat, which can diminish the performance and lifespan of the lighting fixtures. By dissipating heat effectively, aluminum coils help maintain optimal operating temperatures, ensuring the lights operate at their highest efficiency. Furthermore, aluminum coils are lightweight, making them easier to handle and install. This reduces the overall weight of the lighting fixtures, making them more convenient to mount and manipulate during installation. The reduced weight also translates into lower energy consumption during transportation and installation, ultimately contributing to energy efficiency in the long run. In addition, aluminum coils are highly durable and resistant to corrosion, which is crucial for lighting installations exposed to various environmental conditions. This durability minimizes the need for frequent replacements or repairs, reducing energy consumption associated with maintenance. Moreover, aluminum is a recyclable material, meaning that the coils can be easily reused or repurposed at the end of their life cycle. Recycling aluminum requires significantly less energy compared to producing new aluminum, resulting in a reduced carbon footprint and lower energy consumption overall. Overall, aluminum coils offer numerous benefits in terms of energy efficiency for lighting installations. Their efficient heat dissipation, lightweight nature, durability, and recyclability contribute to optimized performance, reduced energy consumption, and a more sustainable lighting solution.

- Q: What is the typical thickness of aluminum coils?

- The typical thickness of aluminum coils can vary depending on the specific application and industry. However, commonly used thicknesses range from 0.015 inches (0.38 mm) to 0.25 inches (6.35 mm).

- Q: Are there any limitations to the widths of aluminum coils?

- Yes, there are limitations to the widths of aluminum coils. The maximum width is determined by various factors such as the capabilities of the manufacturing equipment, transportation limitations, and the desired application of the aluminum coils. Additionally, the thickness and weight of the coil can also influence the maximum width that can be achieved.

- Q: How are aluminum coils used in electrical applications?

- Aluminum coils are extensively used in electrical applications due to their excellent conductivity and lightweight properties. They are primarily used in transformers, motors, inductors, and generators, where their high electrical conductivity efficiently transmits and distributes electric currents. Additionally, their lightweight nature allows for easy installation and reduces the overall weight of electrical equipment.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction.However, isn't aluminium oxide an amphoteric oxide that can react with both acids and alkalis?

- Like hell, it can.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- The common surface finishes for aluminum coils in the electrical industry include mill finish, anodized finish, and painted finish.

- Q: Can aluminum coils be used in the aerospace industry?

- Indeed, the aerospace industry finds great utility in aluminum coils. The extensive use of aluminum in this sector is attributed to its advantageous characteristics, including its low density, impressive strength-to-weight ratio, and exceptional resistance to corrosion. The manufacturing of numerous aircraft elements, such as fuselage panels, wings, and structural frameworks, often relies on the employment of aluminum coils. These coils can be effortlessly molded into various shapes and sizes, allowing for design flexibility and a reduction in overall aircraft weight. Moreover, aluminum coils seamlessly integrate with diverse manufacturing techniques like welding, machining, and forming, rendering them a prime selection for the aerospace industry.

- Q: What are the different thicknesses available for aluminum coils?

- The thicknesses available for aluminum coils can vary, but common options typically range from 0.015 inches to 0.25 inches.

- Q: Can recycled aluminum coils be reused to create new ones, or are they only suitable for disposal?

- <p>Old aluminum coils can indeed be recycled and used to make new ones. Recycling aluminum is an efficient process that conserves resources and reduces energy consumption compared to mining and refining new aluminum. The recycling process involves melting the old coils, which can then be reshaped into new coils without losing any of their properties. This makes recycling aluminum coils a sustainable and environmentally friendly alternative to disposal.</p>

Send your message to us

Mill Finish Aluminum Sheet Coil - Alloy 1050, 1060, 1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords