Silhouette T24 Ceiling Grid for Suspension

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

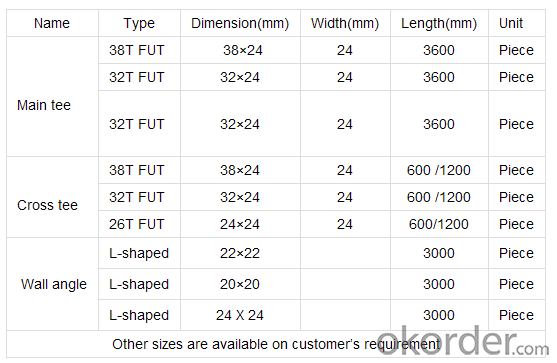

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

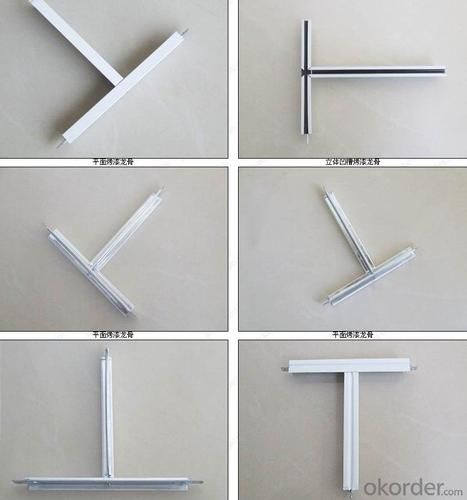

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: I live in a three story condo (I'm on second) and the building was built a year ago. I would like to hang my projector from the ceiling, but do not have a stud finder and can't find a stud. I've poked numerous holes in the ceiling and have only come across a couple pieces of metal, so I moved over to where the next stud should be and there was also metal.Would this be metal studs?

- It could be that your ceiling joist (not studs), are running the other direction. It also could be that your ceiling framing is metal joist. Another option is the ceiling could be suspended on metal grid that allows drywall to be hung form it. Whatever the application-make sure you have a good secure point to fasten to.

- Q: the ceiling tile with no keels.(there are keels inside it but you can't see them cuz they're hidden),so how do you call this kind of ceilig tile?

- Sorry Yangyang, but I don't understand the meaning of keels in the ceiling tiles. There is a style of ceiling called a dropped ceiling where a metal grid framework (often white) hangs lower than the original ceiling and square, often white tiles are placed inside the grid. If any wires or repairs need to be done above the dropped ceiling they can just push up on a tile, do the repairs and then drop the tile back into place. It is seen often in office or industrial spaces and occasionally in residential. It is fairly modern. An older style of ceiling treatment know as a tin ceiling tiles are an antique metal patterned and textured tile that are attached directly onto the ceiling. They are found in old and often expensive homes and sometimes restaurants. Although they are an antique (starting in the 1800s) you can still buy plastic or metal ones to add to a home giving it an old style charm. Are either of these what you are looking for?

- Q: I want a drop-down ceiling for my basement, you know with panels and a grid. What is the average cost for a pretty large room? Don't worry about a contractor. My dad is a contractor so no cost for installation. I don't think you even need a contractor for this though. I just need to know if it's affordable. I have a large basement and we need to be able to access the vents and pipes easily through the panels. There's no other option (unless there's an alternative). Thanks :D

- affordable is what you can afford..however..measure the area and go to home depot or Lowe's and see how much you are looking at in materials..and if dad will do the install for free that's a plus..now there is the dry wall the ceiling option but as you stated earlier you need to have access to vents and pipes..so the smart choice obviously is to do a drop ceiling..the latter will hurt more with dry wall trying to re patch and repair anything later above the ceiling..and with the drop ceiling you can figure out if you can afford to do 10x10 sections or the hole thing at once..very much affordable and very wise choice..

- Q: does anyone know what those things are installed in commercial open-ceilings.. they are like foam materials used as insulation? I need the exact name and need to find a ceiling contractor asap, thanks !!

- I think you are reffering to what is called a drop ceiling or sometimes a grid ceiling. If that is the case the panels are made from mostly fiberglass now and some older ones are made of fiberglass and wood fibers ( cellulose ) .home depot can find a good installer at a reasonable price in your area. IF you are near northeast ct I know of several contractors that do that type of work IM me for more info

- Q: For example, T-keel ah, triangular keel ah, aluminum keel ah, etc., belong to the paint keel it

- Paint refers to the appearance of the wooden door, the surface of the door sprayed with different colors of paint, baked in the barn inside; keel refers to the structure inside the wooden door, some hollow, that is, outside the two sides of the panel, what No, you knock to listen to the sound to know.

- Q: Light steel keel hanging flat how to calculate the material?

- Material usage Gypsum board 1.05 square meters Main keel 1.22m Vice keel (including crossed keel) 4.45m Side keel 0.44m Keel pieces of 3.05 Deputy keel connection 0.83 Main keel connection 0.43 25mm tapping screw 29 Pendant 8.8 Cracked paste 0.50kg Seam tape with 1.50m

- Q: It is good for wood keel or light steel keel

- Sure to shop wood keel, because the trees themselves have Zhang, will be deformed. Pavement on the keel can control the deformation, and increase foot feeling. There is also a solid wood flooring. Europe and the United States are using this stuff, they not only pay attention to environmental protection, but also pay attention to environmental protection, is the entire ecological environment. Its structure is the biggest difference. Surface hardwood with long growth cycle. Core layer and the bottom of the selection of soft pine or fir criss-cross, generally multi-layer and three points, do not need to play keel. Its structure is enough to overcome the surface of the Zhang, and feet comfortable. But choose a solid wood flooring to choose a big brand, because the process requires high, and the need for strong liquidity

- Q: How many millimeters are the main keel spacing during the construction of the lightweight steel keel ceiling?

- Bears With the level of each wall in the room (column) angle out of the horizontal point (if the wall is longer, the middle is also appropriate to copy a few points) Pop-up line (level according to the ground is generally 500mm), from the level of the ceiling to the height of the design plus 12mm (a Layer of white plate thickness), with the powder line along the wall (column) pop-up line, that is, the tail of the keel down the skin line. Simultaneously, According to the ceiling plan, in the concrete roof pop-up main keel position. The main keel should be from the center of the ceiling to the two points, the largest Spacing of 1000mm, and marked the fixed point of the boom, the fixed point of the boom spacing 900 ~ 1000mm. Such as encountering beams and tubes The fixed point of the road is greater than the design and procedure requirements, and the fixed point of the boom should be increased.

- Q: Light steel keel expensive or aluminum alloy keel expensive? What are the characteristics of each

- There is a kind of paint keel is made of iron. Also T-type. But relatively soft. Own grasp.

- Q: The existing light steel keel partition wall of the location is not good, would like to change another position, is to block the original door, and then open a door in the original door door, experts told me how to construction?

- Hello there. Do you mean that you are not moving on the basis of the original door position? While the need to seal off part of the other side of the need to remove part of the light steel keel wall, the height of the door If so, this is technically achievable.

Send your message to us

Silhouette T24 Ceiling Grid for Suspension

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords