Ceiling Grid Systems for Suspension Ceiling Decoration

- Loading Port:

- Shanghai,China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL pc

- Supply Capability:

- 30 Containers/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Suspended Ceiling Grid :

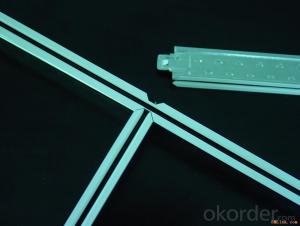

1. There are Flat system, Groove system and Slim system for t grid

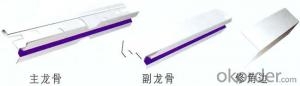

2. Four kind of tee make up of a ceiling frame. those are main tee, long cross tee, short cross tee and wall angle

The height normally is 38 or 32, thickness from 0.20-0.40MM

The normal size as belows(pls mainly focus on the lenghth we have):

main tee:38*24*3600mm or 38*24*3660mm

main tee:32*24*3600mm or 32*24*3660mm

long cross tee:26*24*1200mm or 26*24*1210mm

Short cross tee:26*24*600mm or 26*24*610mm

wall angle:24*24*3000mm or 24*24*3050mm

wall angle:21*21*3000mm or 21*21*3050mm

Applications of Suspension Ceiling Grid:

1.commercial ceiling suspension grid for false ceiling

Package of Suspension Ceiling Grid

1.main tee:30 pcs in one carton

2.long cross tee: 50 pcs in one carton

3.short cross tee:75 pcs in one carton

4.wall angle:50 pcs in one carton

Production Line of suspension ceiling grid

We have 6 production line for ceiling grid, 30 containers per month.

- Q: we have had rain damage to our ceiling, how do i replace it

- If they are the ceiling tiles that lay in a metal grid that's easy. Pick them up and drop new ones in. If they are the smaller ones that staple to the ceiling then just pull them and restaple new ones up. If thy come down hard you can take your utility knife and cut around the perimeter and then replace them . If they are not bad but just stained you can repaint then with a stain blocker paint. Good luck and have fun!

- Q: each point on the grid. The weight of each 4x4 area is 144# ( square footage is 9# PSF ) which I divide into four seperate areas and come up with a reaction so I know what spring to use at each point. The basic areas are easy to calculate because it's either rectangular or square but some areas are cut up, for example there are areas shaped like an L on the grid with two rectangular sides and I don't know how to get their reaction because there are more than four points. Could someone show me a formula for this?

- Sounds like you will probably need to break up the oddly shaped areas, and consider them as a collection of rectangles. However, my understanding is still a little fuzzy. What's this reaction stuff? I don't have a clear picture of the layout in my head.

- Q: the condensate detail shows a 15 dirt leg, then to a tee, then horiz. strainer, valve then steam trap which drops it another 4 . With just going straight horizontal out of coil then the trap I am 3 above ceiling grid will this work ok?

- no. you need the strainer inline before the trap.

- Q: Light steel keel dry wall nail and ordinary dry wall nail What is the difference?

- Ordinary family do not forget to install water purifier. Some people say: we have been drinking tap water.

- Q: I need to attach track lighting in an office with acoustical tiles. Can I screw the track directly into the metal tracks of the suspended ceiling? (running power is not a problem to the track, but the tiles have to stay)

- yes you can screw the trac to the celing grid, just use some really small head screws

- Q: Using the same concept of as that of a motor vehicle stater motor.

- you will desire to be interested in a dynamotor. that's a unit containing a motor and a generator. Many militia radios from international conflict 2 used 12 volt ability from trucks and used a dynamotor to generate 250 volts to turn on the vacuum tubes. You seem interested in creating 33,000 volts from a thousand volts at 5,000 watts. this might artwork, however the main up-tp-date you will desire to draw from it would be 5/33 , that's 0.151515 Amps at 33,000 volts if it have been a hundred% useful. As actual everyone else noted you are able to not get extra advantageous than a hundred% performance, and in prepare dynamotors have been extra like 30% so the optimal modern you will desire to get may well be some million/20 amp. do not attempt it with out expert help with the aid of fact 33,000 volts will leap approximately 2 inches by air and a million/20 amp is extra beneficial than adequate to kill somebody.

- Q: I'm looking to mount the two front speakers and center speaker of a 5.1 surround sound home theater system onto my ceiling. My only concern is that I have ceiling tiles in this room, which means that the tiles can move. Can I mount speakers onto ceiling tiles? If I can't, are there any other solutions that will allow me to somehow have the speakers hang from the ceiling? All three speakers weigh 2.2 pounds each, and I guess combined with a mount it would be a little more.

- you can mount them to the metal frame, check to see if there is enough wire to hold the extra weight also. tile is to weak dont even try.

- Q: In the decoration of light steel keel + blockboard + gypsum board + latex paint this practice? I think with light steel keel is like a gypsum board is like, and now the construction side that there is no way to let the sky keel will be down one meter, can only do with light steel keel. I think they are not lying to me. Please know the big friends help out

- There is such a practice. Not lie to you, you rest assured. Sometimes, due to the needs of the shed, had to use blockboard and light steel keel combination. If the ceiling hanging will be one meter, it is best to use the expansion bolt to fix the hanging in the original shed.

- Q: Is there any requirements regarding hard wired smoke detectors on a suspended ceiling?I know luminaires are supposed to be properly secured to the grid, do smoke and CO detectors need to be? If so how?Right now, all I have is some old work boxes for the splices.I'm looking for a correct answer, I'm not going to cut corners.NEC code references are a plus.

- Yes there are: Because the hard wired smoke detectors are connected to 120 volts they fall under the NEC Wiring methods NEC Article 300. The specific location is 300.11 It gives all of the rules about not using the grid support wires as a method of sole support. You do have to add a support wire the same as a luminary. The best way to attach the old work boxes is to use a bracket called a T-bar they are made by Caddy and several other companies. You also have to make sure that the suspended ceiling is not being used as a return air path for a forced air system because the NFPA 72 states that the minimum distance from a return air to a smoke or CO2 detector is 3 feet. Hope this answers your question :)

- Q: there will not be anything stored above this ceiling. insulation will be used between the beams plus electrical fictures.

- 24 feet is a large span ...im a builder in uk ...you never gave the other dimension ..if its smaller ..that's the way to go ...however if we used a steel beam for that span it would need to be at least 12deep by 6wide ..a lot for a non loadbearing situation ...the joist would be 7x2 at 16centres....on any steel you will need padstones where they sit ..either concrete or blue brick

Send your message to us

Ceiling Grid Systems for Suspension Ceiling Decoration

- Loading Port:

- Shanghai,China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL pc

- Supply Capability:

- 30 Containers/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords