T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

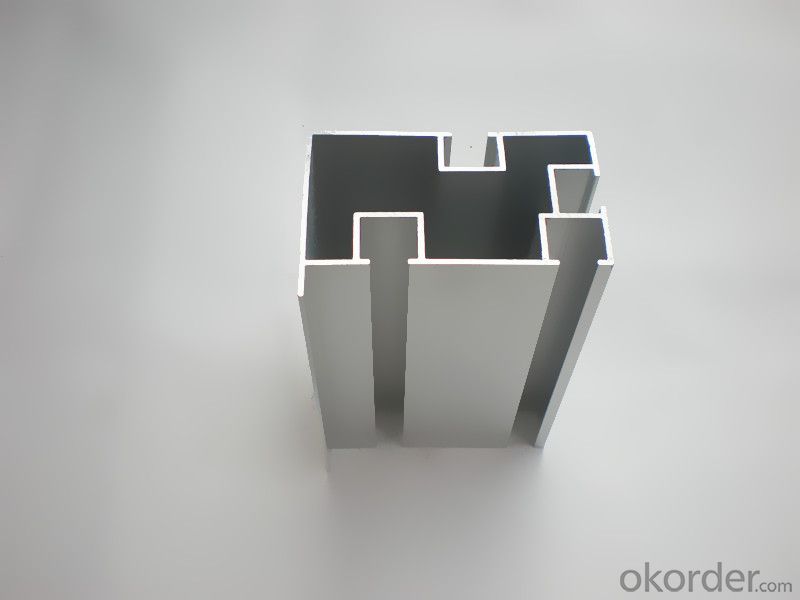

1.Structure of Aluminum Profile 6063 t5 Aluminum Extruded Profiles Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6063 t5 Aluminum Extruded Profiles :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

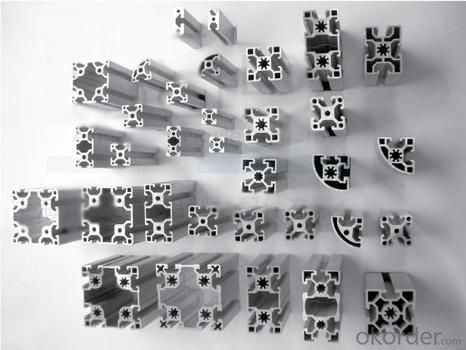

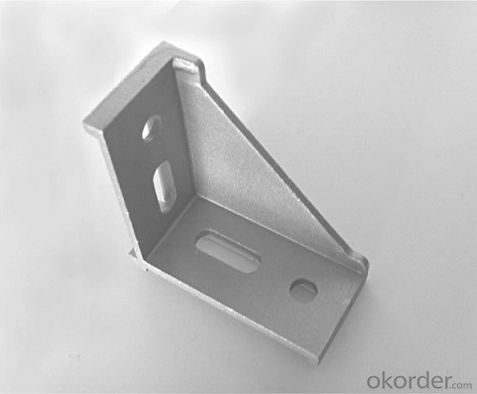

3.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Images:

4.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks if aluminum profiles are suitable for both exterior and interior uses.

- <p>Yes, aluminum profiles can be used for both exterior and interior applications. They are popular for exterior use due to their resistance to weather and corrosion, making them ideal for construction and architectural projects. For interior applications, aluminum profiles are valued for their strength, lightweight, and aesthetic appeal, often used in furniture, window frames, and decorative elements. Their versatility and durability make them a preferred choice in various settings.</p>

- Q: What are the standards and regulations that control the use of aluminum profiles in construction?

- <p>Yes, there are several standards and regulations that govern the use of aluminum profiles in construction. These include international standards such as ISO 7039 and ISO 8039, which specify requirements for aluminum alloy extruded profiles. In the United States, the American Architectural Manufacturers Association (AAMA) provides guidelines, and the Aluminum Association sets standards for aluminum products. European standards like EN 755 and EN 12206 cover aluminum extrusions for general purposes and structural applications. Compliance with these standards ensures the safety, durability, and performance of aluminum profiles in construction projects.</p>

- Q: What are the ten brands of aluminum alloy profiles?

- Top ten list of Chinese aluminum profiles Enterprises1 、 aluminum material(China Aluminum Group, China's top ten aluminum enterprises, central management of large state-owned enterprises)2 - Asia - South Asia(China famous trademark, China famous brand, China aluminum profile enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3, the United States and aluminum(A Well-Known Trademark in China, China brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4, the phoenix aluminum aluminum(China famous brand, famous brand in Guangdong Province, Guangdong province famous brand products, Guangdong Feng Aluminum Co. Ltd.)5, Zhong Wang aluminum(China famous brand, China famous brand, Liaoning famous brand product, China Zhong Wang Holdings Limited)6, Hing Fat aluminum(China brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7, pillars of aluminum(listed companies, Chinese famous brands, China's well-known trademarks, China's aluminum enterprises ten, Zhejiang pillars, new materials, Limited by Share Ltd)8 、 Nanshan aluminum material(China famous brand, China well-known trademark, ten aluminum profile enterprises in China, Shandong Nanshan aluminum & Limited by Share Ltd)9, the court aluminum profiles(China's well known trademark, China's top ten aluminum enterprises, Polytron Technologies Inc, Shanghai aluminum Fair)10, Albert aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong Weiye aluminium factory Co., Ltd.)

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles possess exceptional durability and resilience, making them highly adept at tackling extreme weather conditions. Their inherent resistance to corrosion allows them to endure harsh weather elements like heavy rain, snow, temperature fluctuations, and intense UV radiation without succumbing to deterioration or corrosion. A key characteristic of aluminum is its ability to form a protective oxide layer, known as aluminum oxide, on its surface. This layer acts as a natural barrier, shielding the metal from moisture, salt, and other corrosive agents found in the atmosphere. Consequently, aluminum profiles remain unaffected by rain or snow, and they do not rust or corrode like other metals. Additionally, aluminum's thermal conductivity enables it to rapidly dissipate heat, preventing any harm caused by extreme temperature changes. Regardless of exposure to scorching heat or freezing cold, aluminum profiles undergo minimal expansion and contraction, which helps maintain their structural integrity and prevents warping or cracking. Furthermore, aluminum profiles can withstand high wind loads, making them suitable for areas prone to hurricanes, tornadoes, or strong gusts. Their lightweight yet sturdy composition allows them to endure significant pressure without bending or breaking. Regarding UV radiation, aluminum profiles exhibit excellent resistance to fading and discoloration. They can effectively withstand prolonged exposure to sunlight without losing their original color or surface finish. This renders them an ideal choice for outdoor applications, such as windows, doors, and facades, where they retain their visual appeal and structural soundness even in extreme weather conditions. In summary, aluminum profiles display remarkable durability, corrosion resistance, thermal stability, and resistance to UV radiation, enabling them to effectively handle and withstand the challenges presented by extreme weather conditions.

- Q: What are the advantages of utilizing recycled aluminum in construction projects in terms of environmental impact?

- <p>Using recycled aluminum profiles in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining bauxite, which is the primary source of aluminum. This reduction in mining decreases habitat destruction and soil erosion. Additionally, recycling aluminum requires significantly less energy compared to producing it from raw materials, which cuts down on greenhouse gas emissions and reduces the overall carbon footprint. Furthermore, the use of recycled aluminum helps in waste management by diverting materials from landfills, thereby reducing pollution and the environmental burden of waste disposal.</p>

- Q: Are aluminum profiles suitable for gym equipment?

- Indeed, gym equipment can be made using aluminum profiles. Aluminum, being both lightweight and durable, can endure rigorous use and offer exceptional structural support. Its remarkable strength-to-weight ratio renders it perfect for gym equipment, granting effortless maneuverability while retaining stability and durability. Moreover, aluminum is resistant to corrosion, making it apt for environments abundant in moisture or humidity, like gyms or fitness centers. The versatility of aluminum profiles further allows for the customization of gym equipment to suit precise needs and requirements. Overall, aluminum profiles present a plethora of advantages for gym equipment, establishing them as an appropriate selection for fitness facilities.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: Can aluminum profiles be used in the production of industrial machinery?

- Yes, aluminum profiles can be used in the production of industrial machinery. Aluminum is a lightweight yet strong material that offers excellent strength-to-weight ratio, corrosion resistance, and machinability. It can be easily formed into various shapes and profiles, making it suitable for constructing frames, enclosures, support structures, and other components in industrial machinery. Additionally, aluminum profiles are highly customizable and can be engineered to meet specific design and functional requirements, making them a preferred choice in many industrial applications.

- Q: Are aluminum profiles resistant to chemicals or solvents?

- Yes, aluminum profiles are generally resistant to chemicals and solvents. Aluminum is known for its excellent corrosion resistance, and this property extends to its resistance to most chemicals and solvents. However, it is important to note that the level of resistance can vary depending on the specific chemical or solvent involved. Some highly corrosive chemicals or solvents may still have an effect on aluminum profiles over time. Therefore, it is advisable to consult the manufacturer or conduct specific tests to ensure compatibility with a particular chemical or solvent.

- Q: This question asks about the various types of fasteners that are used to secure aluminum profiles in construction projects.

- <p>In construction, several types of fasteners are used to secure aluminum profiles. These include: 1. Bolts and Nuts: Commonly used for joining aluminum profiles, they provide a strong and secure connection. 2. Rivets: These are used for permanent connections and are ideal for load-bearing applications. 3. Screws: Self-tapping screws are often used for joining aluminum profiles without the need for pre-drilling. 4. Adhesives: Structural adhesives can be used for bonding aluminum profiles together, providing a strong and durable joint. 5. Clamps and Brackets: These are used to temporarily or permanently secure aluminum profiles in place. 6. Connectors and Brackets: Specifically designed for aluminum profiles, these connectors provide a secure and aesthetically pleasing joint. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

Send your message to us

T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords