Sapa Aluminum Profiles for Shower Room OEM Aluminum Extrusion for High Voltage Switchgear

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Shower Room OEM Aluminum Extrusion for high voltage Switchgear Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Shower Room OEM Aluminum Extrusion for high voltage Switchgear:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

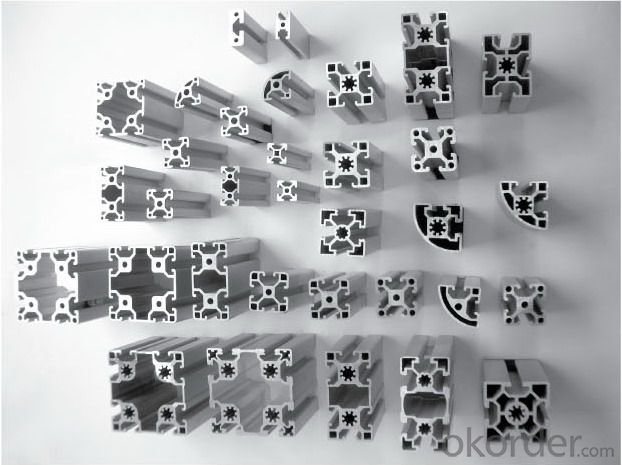

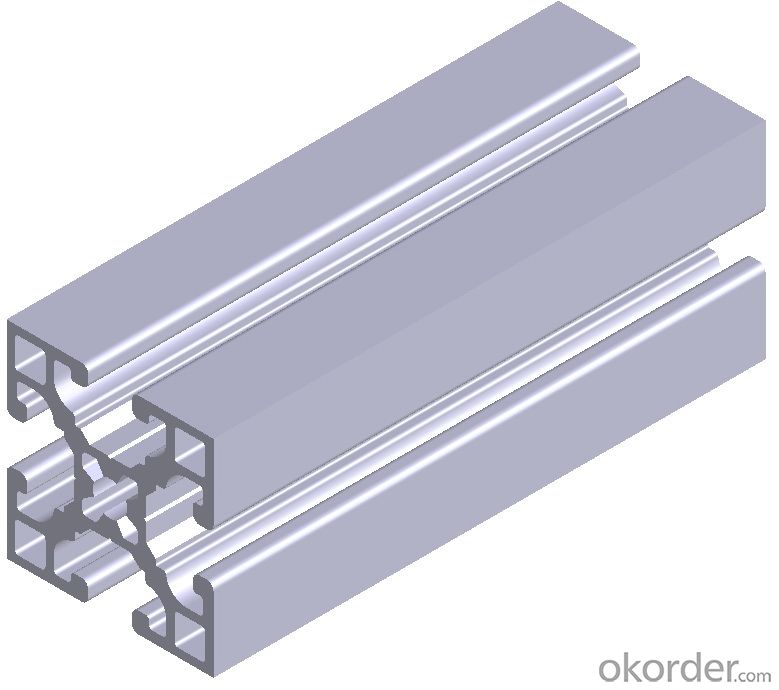

3.Shower Room OEM Aluminum Extrusion for high voltage Switchgear Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- A section of properties in CAD labeled dynamic block, the section area and mark block association graph can be easily calculated, section area, surface area, weight theory, and the setting up of a variety of materials such as aluminum options.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: Calculation of heat dissipation of aluminium profile radiator

- This requires software that is not easy to compute directly, and the formulas may pull out a long string and are inaccurateBecause the contact of the bottom of the profile is initiated by the heat source, the contact area is first set, which affects the distance and conduction angle of the thermal conductivityWhen you change this condition, the whole formula varies greatlyAgain, set convection and convection intensities, convection fluid properties and relative heat exchange efficienciesIn the radiator industry, there have been similar formulas, but only the natural convection settings, and in the heat under the state, heat dissipation at room temperature settingsProfessional software has many, FLOWTHEM, e-therm, ice-pake and so on, even Pro-E seems to be able to hang modules to do simulationSuggest going directly to software

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: Can aluminum profiles be used in the production of industrial robots?

- Yes, aluminum profiles can be used in the production of industrial robots. Aluminum is a lightweight and durable material that offers several advantages for constructing robotic systems. It has a high strength-to-weight ratio, making it suitable for building rigid and reliable robot structures. Aluminum profiles can be easily machined, allowing for precise and intricate designs to be created for various robot components such as frames, arms, and joints. Additionally, aluminum is corrosion-resistant, which is beneficial in industrial settings where robots may be exposed to harsh environments or chemicals. Overall, aluminum profiles provide a cost-effective and versatile solution for manufacturing industrial robots.

- Q: Can aluminum profiles be used in the production of food processing equipment?

- Aluminum profiles are indeed applicable in the production of food processing equipment. They possess a number of advantages for this purpose due to their lightweight and versatile nature. Their non-toxic and non-corrosive properties make them an ideal option for use in food processing environments where hygiene is of utmost importance. Moreover, aluminum profiles can be effortlessly cleaned, exhibit high resistance to chemicals, and remain unaffected by moisture or humidity. In addition, aluminum serves as an efficient heat conductor, which is crucial for ensuring effective food processing. Furthermore, it boasts exceptional structural strength and can be easily fabricated to produce customized equipment. Overall, aluminum profiles are widely favored in the food processing industry owing to their enduring nature, versatility, and hygienic attributes.

- Q: How do aluminum profiles contribute to water management strategies?

- Aluminum profiles play a crucial role in water management strategies due to their inherent properties and versatility. These profiles are commonly used in the construction of various water management infrastructure such as pipes, channels, and tanks, among others. Firstly, aluminum profiles are lightweight yet sturdy, making them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems as it reduces the risk of leaks and damages, ensuring the efficient and effective transport of water resources. Secondly, aluminum profiles are highly resistant to corrosion. Corrosion is a major concern in water management as it can contaminate water, reduce its quality, and damage infrastructure. By utilizing aluminum profiles, the risk of corrosion is significantly reduced, leading to improved water quality and longevity of the infrastructure. Additionally, aluminum profiles are highly customizable and can be fabricated into various shapes and sizes, allowing for the creation of efficient water management systems. These profiles can be used to construct channels, culverts, and tanks, which are crucial components of water management infrastructure. The versatility of aluminum profiles enables engineers and designers to create efficient and effective systems that can handle large volumes of water, ensuring proper water management in various scenarios such as irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By using aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. In summary, aluminum profiles have a significant impact on water management strategies. Their lightweight yet sturdy nature, corrosion resistance, versatility, and sustainability make them indispensable in the construction of water management infrastructure. By utilizing these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q: Can aluminum profiles be subjected to painting or coating processes to improve their aesthetic appeal and resistance to wear?

- <p>Yes, aluminum profiles can be painted or coated. This process not only enhances their appearance but also significantly improves their durability and resistance to corrosion. Aluminum has a natural oxide layer that provides some protection, but painting or coating can offer additional layers of defense against environmental factors. These coatings can be applied through various methods such as powder coating, anodizing, or electrophoretic deposition, each providing a different finish and level of protection. The choice of coating depends on the specific requirements for appearance, performance, and the environment in which the aluminum profile will be used.</p>

- Q: What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and diverse. Standard options usually include silver, bronze, and black anodized finishes. However, these profiles can also be powder-coated in a wide range of colors, allowing for customization to match any aesthetic or design preference.

- Q: Are there any limitations or drawbacks of using aluminum profiles?

- Yes, there are some limitations and drawbacks of using aluminum profiles. One limitation is its lower strength compared to other materials such as steel. Aluminum profiles may not be suitable for heavy-duty applications that require high tensile strength or load-bearing capacity. Therefore, in certain scenarios, steel or other materials may be preferred. Another drawback is that aluminum is more prone to corrosion compared to materials like stainless steel. Although aluminum profiles can be treated with protective coatings, they may still be susceptible to corrosion in harsh environments or if not properly maintained. This can affect their durability and longevity. Furthermore, aluminum profiles may have higher initial costs compared to other materials. The production and processing of aluminum can be more expensive, which can impact the overall cost of using aluminum profiles in construction or manufacturing projects. Lastly, aluminum profiles may have limitations in terms of design flexibility. While aluminum is relatively easy to shape and mold into various profiles, it may not be as versatile as some other materials. This can limit the options available for complex or intricate designs. Despite these limitations and drawbacks, aluminum profiles still offer many advantages such as lightweight construction, excellent thermal conductivity, and resistance to electrical conductivity. Therefore, it is essential to carefully consider the specific requirements and constraints of a project before deciding to use aluminum profiles.

Send your message to us

Sapa Aluminum Profiles for Shower Room OEM Aluminum Extrusion for High Voltage Switchgear

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords