T Bar for Ceiling Grid - 3600mm Suspension Ceiling Grid System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

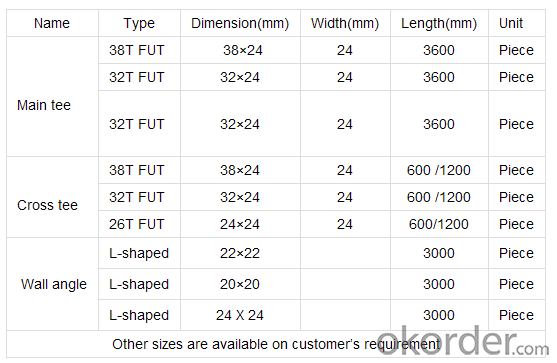

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Light steel keel partition keel spacing 300, the number of meters per square meter vertical keel?

- Light steel keel gypsum board partition, the main materials and accessories requirements 1. Light steel keel main pieces: along the top keel, along the keel, strengthen the keel, vertical keel, horizontal keel should meet the design requirements. 2. Light steel skeleton accessories: support card, Cato, angle care, connectors, fixtures, wall keel, pressure and other accessories should meet the design requirements. 3. Fastening materials: nail, expansion bolts, galvanized self-tapping screws, wood screws and adhesive joints should meet the design requirements. 4. Fill the sound insulation material: according to the design requirements. 5. Overlay plate: Gypsum board specifications, thickness by the designer or by drawing requirements selected.

- Q: Home furnishings are light steel keel + cement board + hanging network to do partition, but always listen to the craftsman said that this is not good, generally there are several bad, one is the rainy season will be anti-water, brush paint will peel off; Do not bear the weight, do not hang TV; third is to tear the wall will crack, or load not work. Is it in the line?

- Or the walls of the sound of the wall is not just not what you said that the shortcomings

- Q: Light steel keel with what cut

- Cutting machine, scissors can also be used

- Q: Ok, I need to know if they either prevent conduction, convection or radiation . I also need to know how they prevent these thermal energy transfer mechanisms (conduction,radiation and convection) from occuring.

- Tall trees: If you have tall trees around your house, your house will be cooler because of the shade. The trees are blocking radiation from the sun, and to a lesser extent stopping convection to the air around the house by acting as a wind block. The air around your house removes heat through open, free convection. Polystyrene: The polystyrene panel itself has less conduction than other materials because it is less dense. Conduction is essentially shaking the atoms of the materials. Less dense things typically have less atoms to shake. (There are exceptions). But if you are talking about a dropped ceiling (with the panels haning from the real ceiling in the metal grid) as a whole system, there is more to it than that. Without the panels, you would lose heat to your roof (and the world outside) by convecting from your room to the ceiling, CONDUCTING through the ceiling, and convecting to the world outside. Your sandwich would be: Outside world Ceiling Room air But a dropped ceiling adds some more layers in there, most importantly a space of dead air, which is an excellent insulator - similar to a thermapane window. Your sandwich would become: Outside world Ceiling Dead (not moving) air between polystyrene panels Polystyrene panels Room air The extra layer in the sandwich helps. Polystyrene makes a good insulator, but it would still work if you dropped a ceiling with metal panels because of the dead air. In heat and mass transfer problems, it is critical that when you ask the question, you define what the system boundary is. My answer is long because I don't know what that is in your question. Hope it helps.

- Q: I want to install a dropped ceiling, my basment is 22 x 32. What materials do I need and how much do I need?

- The material, approximately 2 x 4 comes in cases of approx. 12 pieces. The rails (both perimeter and spanning/ interlocking supports (perpendicular) / wiring to hang, can be figured; as answer one suggests. No offense but you and the supplier can do the math. You should ask about a return policy especially for the extra hardware. Buy and Keep extra panels. Tools: Tin shears. hack saw; nail gun perhaps; utility knife; ome kind of straight edge; tape measure; wire cutters If there is no plumbing or electrical above; and/or no major AC ducting; allow no less than 8 inches of hang to fit the tiles. Steven Wolf

- Q: What is the world keel and light steel keel? What is the use of ah?

- In the partition between the roof and the roof and the ground at the junction of the laying of the keel, called the heaven and earth keel, which will have a vertical keel to do support, as well as through the keel from the vertical keel interspersed into the middle, play a reinforcement

- Q: T-type light steel keel TB24 * 38 What does it mean?

- DU38 * 12 * 1.0 is not on the people DU50 * 15 * 1.2 and DU60 * 27 * 1.2 are superior keel

- Q: While I won't get into the reasons why, I ended up drywalling my walls in a small sitting room in my basement before doing the ceiling. The walls have since been painted. What are my options for installing drywall in the ceiling and what types of roadblocks may I encounter when doing so?

- With no offense, OOPS. In any case it isn't a capital offense crime. After installing thousands of sq. ft. of drywall I offer that the process will be much the same as if the walls were still just studs. Certainly a helper or two would be nice, but the job can be tackled by a single, with some effort. If you have two like sized step ladders they can help. You can make braces from 2 x 4's to hold up a sheet, once you manage to get it up. The braces can also be used to boost: the sheet to the ceiling then wedge/hold it in place. Once screwed to the rafters/ joists all you need do is tape, mud, sand, and eventually paint. If you happen to NEED it white you can mask off your walls at the meeting points. I've also applied thousands of gallons of paint and have a suggestion. Assume your walls are a color. It is a trick of the eye perhaps, but glaringly noticeable to anyone if the painter didn't have a steady hand, and happened to get color up onto the ceiling. The better process for a DIY especially, is to cut the ceiling down onto the walls, and then paint the wall color to within 1/16th inch of the ceiling in a masked, straight line. Odd how it works, but it does. Steven Wolf

- Q: i found mold in one of my buildings and would like to be able to get rid of it. its localized in the ceiling above the ceiling grid above the bathroom. how do i get rid of it to make the area safer to use. is it necessary to hire a professional or is there something i can do myself to save money.

- Mold is a sign of moisture in the area. If you don't have an exhaust fan in the bath, you may need to install one. Another wise you need to find where the moisture is coming from. Leaking roof, water pipe? And yes plain old laundry variety bleach will kill mold.

- Q: Tooling, specifications have no provisions Light steel keel ceiling to brush fire paint?

- Do not use light steel is the thickness of 0.5 1.0 galvanized steel strip

Send your message to us

T Bar for Ceiling Grid - 3600mm Suspension Ceiling Grid System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords