Short Span Ceiling Grid T Bar Suspension System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (T Bar Suspension Grids) Description

T Bar Suspension Grids

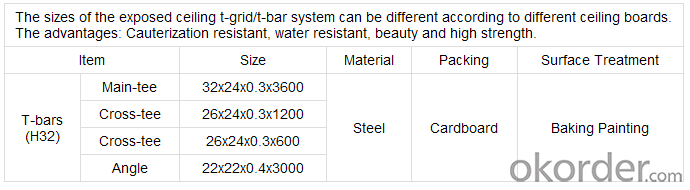

1. main tee 32*24*3600*0.3mm

2. cross tee 26*24*1200/600*0.3mm

3. wall angle 22*22*3000*0.4mm

Ceiling T Section /Ceiling Grids

Supported by a team of adroit and decimated professionals, we are providing high quality Ceiling Suspension System. The Ceiling Suspension Systems have demountable design and are capable of installing any tiles of size. Our suspension system are improved, eco-friendly, easy to install suspension systems feature corrosion resistance for interior environments. We are engaged in offering Ceiling Suspension System that is uniquely designed according to the industry standard of compatibility. These systems are valued by the clients for acoustical tile, light fixtures, air diffusers, seismic and fire resistive designs.

Production line:

2,Main Features of the (T Bar Suspension Grids)

Features:

high zinc coating

Corrosion resistance

Eco friendly

Easy to install

(5)Standard Size:

a. Regular flat T grid

Main tee: 38*24*3000/3600mm,

32*24*3000/3600mm

Cross tee: 26*24*600/1200mm,

30*24*600/1200mm

Wall angle: 22*22*3000mm, 20*20*3000mm

b.Slim Plain T grid

Main tee: 38*14*3000/3600mm,

32*14*3000/3600mm

Cross tee: 26*14*600/1200mm,

30*14*600/1200mm

Wall angle: 20*15*3000mm

c .FUT(Elite) T grid

Main tee: 38*24*3000/3600mm,

32*24*3000/3600mm

Cross tee: 26*24*600/1200mm,

30*24*600/1200mm

Wall angle: 22*22*3000mm, 20*20*3000mm

d.Silhouette T grid

Main tee: 38*14*3000/3600mm,

32*14*3000/3600mm

Cross tee: 26*14*600/1200mm,

30*14*600/1200mm

Wall angle: 20*15*3000mm

Other dimension is aslo available!/It can be customized in accordance with clients’ requirements

(6)Main Thickness: 0.23mm, 0.24mm, 0.25mm, 0.26mm, 0.3mm,0.35mm,0.4mm, etc.

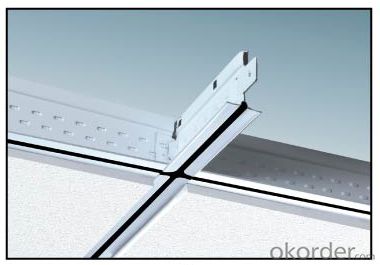

3,(T Bar Suspension Grids) Images

4,(T Bar Suspension Grids) Specification

5,FAQ of (T Bar Suspension Grids)

1. Elegant in style and nice looking.

2. High strength, good quality.

3. Cauterization resistant, water resistant.

4. Rustproof, fire resistant, stainless, rust resistant and convenient application.

5. High quality material, moisture proof, anti-corrosive, non-deforming, fadeless.

6. High precision, high symmetry, high close fitting.

7. Strong bearing capacity.

8. Safe, firm and easy to match with all kinds of mineral fiber board and gypsum board.

- Q: Light steel keel CB38 * 12 What does it mean?

- Refers to the main keel with 3.8cm × 1.2cm, which is often said 38 main keel. There are 38 holes in the wall

- Q: How much is the base price?

- Whether there is a drop level, the two top layer sets of quota artificial coefficient 110, set the amount of light steel keel on the gypsum board, the material in the gypsum board thickness defaults to 12, do not meet the site Please adjust, base price do not know where you are , I am Qingdao side, in accordance with the 2017 price list, the provincial base price of 230.54 yuan / 10 square meters, the regional price of 239.93 yuan / 10 square meters, hoping to help you, this price is flat top price

- Q: Asked the next ye demolition? I want to split myself. And then how to restore the floor, the walls of the hole are ye recovery? A little window also marked, we supposed to? Because it is rented house

- In the absence of the use of marble glue and other adhesives in the case of removal of light steel keel gypsum board wall steps: 1. First find the automatic screw, remove the tapping screws; 2. Remove the gypsum board; 3 remove the keel (according to the order of the keel installation, reverse order to remove the keel. Keel of the general installation order: the main keel - vice keel); In the case of the use of marble glue, the gypsum board can only be damaged.

- Q: Gypsum board shed light steel keel production

- Cost, 9.5 gypsum board 17.6 a 2.88 square, gypsum board price of 6 yuan, keel 10 yuan (the main keel and vice dragon, hanging tendons, corners) around, artificial 8-10 yuan.

- Q: Now there is a theater decoration, ceiling no steel structure maintenance rack, ceiling ceiling height of 5 meters, Party asked directly with screw rod hanging, but the screw is not 5m long, there is no specification requirements, the maximum length of the screw can not exceed

- Can be knotted or welded

- Q: Gypsum board light steel keel cut off how much money 1 square

- Light steel keel skeleton 20 yuan per square meter, gypsum board double-sided 1.2cm thick plus 18 yuan / square, labor costs in about 20 yuan / square, if placed on the noise cotton to add 3, plus loss, other dressings generally About 65 yuan (without paint)

- Q: Normal gypsum board and light steel keel do the wall how much money a square?

- Ordinary snowflakes 75 keel 20 yuan / square meters, double gypsum board ordinary 20 yuan / square meters, labor costs 20 - 30 yuan / square meters (points with or without noise rock wool), if the high-grade materials, the price 90--160 yuan / square meters. There are professional wall keel system, the price of 200 yuan / square meters.

- Q: How to calculate the number of light steel keel required per level of various materials

- Not less if the room too much too small, it may not be enough, need to consider the increase in the main vice keel! The main keel spacing in the 800-1200, vice keel 600

- Q: Here is what I have...a wire that looks like a regular cord for a plug in and a copper looking wire I assume is the ground. In the drop ceiling I have two wires that seem to have been been cut from electric cord and hard wired into another track lighting. I have had a light up here before but have not ever previously hooked electric up. I know it can handle the electric current. There are caps at the end of the wires so I am assuming (love assuming) that I can attach the wires from the light to these wires and recap. Then I need to ground the cooper wire, but what is a good ground? It is a drop ceiling so can I attach to the grid or wires holding the drop ceiling? Of course the electric will be off! I am wondering is it possible to cross the two wires and have a big boo boo happen? I appreciate the input. I am really needing to get this completed shortly so please anyone with some expertise respond!

- Ignore Andrew. He has dangerous misinformation. First off, the hot and neutral are not interchangeable. If you don't have white and black, there are other ways of identifying them. The white is neutral, which can also be indicated by ridges on that side (for lamp cord style wire). There are also less common ways, but the bottom line is they are not interchangeable. For the ground, no the ceiling grid is not a ground. If you are in an older house, you may not have a ground available. The best thing then would be to use a fixture that doesn't need one, if you can find one.

- Q: Light steel keel wall is this use?

- Light steel keel wall height of not more than six meters, as for the distance, before the words also useful sixty centimeters, but now is generally forty centimeters, but if the national architectural interior decoration standards, it is thirty centimeters.

Send your message to us

Short Span Ceiling Grid T Bar Suspension System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords