Supply 4x8 430 Stainless Steel Sheet in Wuxi

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

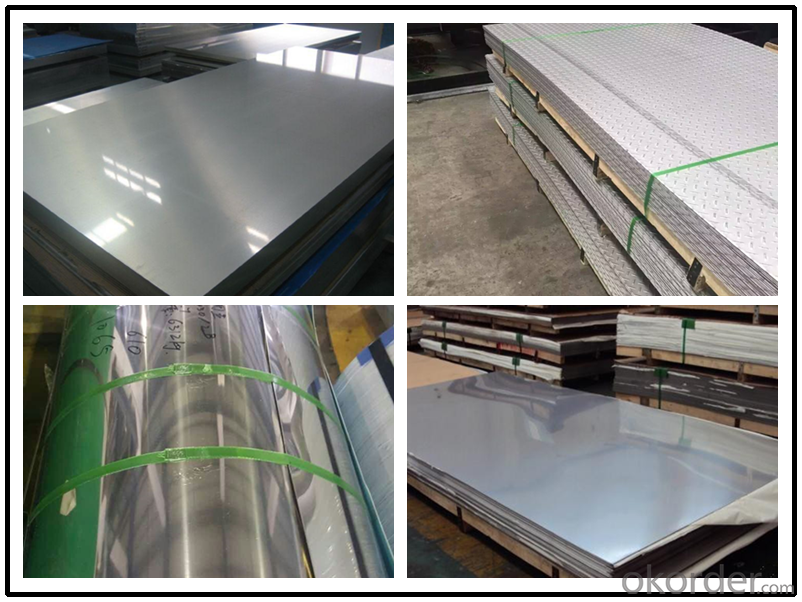

Details of 316L stainless steel sheet

Item | 316l stainless steel sheet |

Standard | AISI |

Material | 316l |

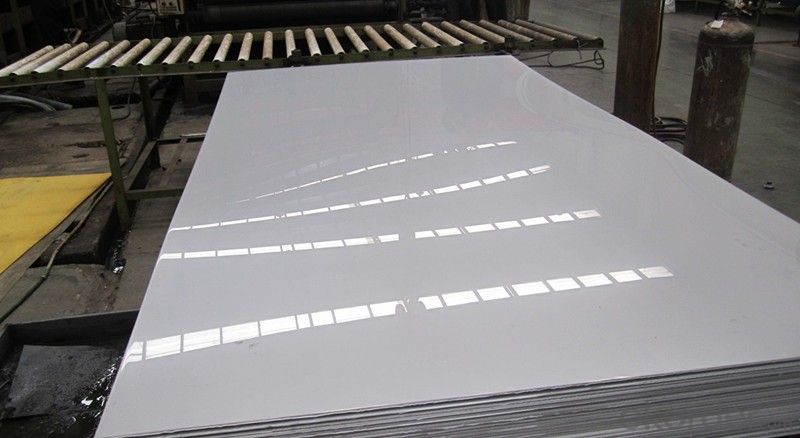

Surface | 2B,BA,NO.1,NO.4,NO.8,8K,hair line etc. |

Thickness | 0.4~100mm |

Width | 1000mm,1219mm,1500mm,1800mm,2000mm,2500mm,3000mm etc. |

Length | 1000,2000mm,2440mm,3000mm,5800mm,6000mm etc. |

Package | anti-water paper wrapped,iron strip fastened,put on wooden pallet,or as required |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

Price term | FOB,CFR,CIF,etc |

Payment term | TT,L/C |

Certificate | We accept the third inspections--SGS-BV etc. |

Chemical Composition

Specifications of Stainless Steel Sheets | |

Grade | 300 series |

| Standard | JIS,AISI,ASTM,GB,DIN,BS |

| Color | Primary |

| Certificate | ISO,SGS,ROHS |

| Thickness | 0.4mm~6mm |

| Width | 1000mm,1219mm,1500mm |

| Length | 1000mm~5000mm or as requirement |

| Application | building decoration , public facilities,anti-corrosion,etc. |

| Surface | NO.1,2B,No.8,No.4,BA,8K,HL |

| Technique | cold rolled & hot rolled |

| Packaging Details | Export sea worthy package + water proof paper + wooden palletin |

| Delivery Detail | In 3--7 working days |

| Surface | Characteristics |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses |

| BA | Cold rolled,bright annealed and skin-passed,the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

| NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarsestria,but thinner than No3,are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| NO.1 | The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks,mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

Packaging & Shipping

Application

- Q: Can the tile be directly attached to the stainless steel plate?

- Yes, but if you want to be smooth and strong, you must first ensure that the tile surface is flat and firm. The best use of woodworking special adhesive, decorative materials shop sell, otherwise not durable, the best post also find a professional carpenter to paste. Stainless steel is recommended with 304, once and for all. If you want to use glass glue cheaply, use neutral glass adhesive. Forgot to give them to me.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- This is mainly the unclean environment and surface protection measures are not done well, stainless steel plate surface water stains even if frosted, not necessarily can be worn off

- Q: How to calculate the weight of stainless steel plate?

- There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: Can stainless steel sheets be used for kitchen utensils?

- Indeed, kitchen utensils can certainly make use of stainless steel sheets. Given its durability, ease of cleaning, and resistance to rust and corrosion, stainless steel stands as a popular option for kitchen utensils. The malleability of stainless steel sheets also allows for the creation of a wide range of utensils, including spoons, forks, knives, spatulas, and more. Furthermore, stainless steel possesses the advantageous quality of being non-reactive, which means it does not release any harmful chemicals into food, rendering it a safe choice for cooking and eating utensils. All in all, stainless steel sheets prove to be an excellent material selection for kitchen utensils due to their robustness, cleanliness, and long-lasting nature.

- Q: Are stainless steel sheets suitable for architectural column covers or cladding?

- Yes, stainless steel sheets are suitable for architectural column covers or cladding. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an excellent choice for exterior applications. It can withstand harsh weather conditions, maintain its appearance over time, and provide a sleek and modern look to architectural structures. Additionally, stainless steel sheets offer versatility in terms of finishes, patterns, and colors, allowing architects and designers to create unique and visually appealing column covers or cladding designs.

- Q: Can stainless steel sheets be used for heat recovery systems?

- Heat recovery systems can utilize stainless steel sheets. Stainless steel is known for its high thermal conductivity and corrosion resistance, making it an ideal material for heat transfer applications. In heat recovery systems, stainless steel sheets are commonly employed as heat exchanger plates or tubes because they efficiently transfer heat from one fluid to another. The corrosion resistance of stainless steel guarantees the durability and reliability of the heat recovery system, even in harsh environments and at elevated temperatures. Furthermore, stainless steel sheets can withstand thermal expansion and contraction, enabling their use in different heat recovery system designs. Overall, stainless steel sheets are a favored option in heat recovery systems due to their exceptional heat transfer properties, long-lasting nature, and resistance to corrosion.

- Q: Can stainless steel sheets be used in swimming pool applications?

- Yes, stainless steel sheets can be used in swimming pool applications. Stainless steel is a popular choice for swimming pool construction due to its durability, resistance to corrosion, and aesthetic appeal. Stainless steel sheets can be used for various purposes in swimming pools, such as pool walls, floors, stairs, and water features. They offer excellent strength and are highly resistant to corrosion caused by chlorine and other chemicals present in pool water. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for swimming pool applications.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To effectively eliminate adhesive residue from stainless steel sheets, the following steps can be followed: 1. Commence by delicately scraping off as much of the residue as possible using a plastic scraper or your fingernail. Exercise caution to avoid scratching the stainless steel surface. 2. Subsequently, moisten a soft cloth with warm water and a mild detergent or dish soap. Employ gentle circular motions to scrub the adhesive residue. Refrain from using abrasive cleaners or scrub brushes as they have the potential to harm the stainless steel finish. 3. If the adhesive residue persists, consider utilizing a non-abrasive cleaner specifically designed for stainless steel. Apply a small quantity of the cleaner to a soft cloth and gently rub the residue until it detaches. 4. In the case of tenacious adhesive residue, a paste can be concocted by combining baking soda and water. Apply the paste to the affected area and allow it to sit for a few minutes. Subsequently, utilize a soft cloth to gently scrub the residue in circular motions. 5. Thoroughly rinse the stainless steel sheet with warm water to eliminate any remaining residue or cleaner. 6. Finally, employ a clean, soft cloth to dry the surface, thereby preventing water spots and streaks. It is important to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet prior to applying it to the entire surface. This precautionary measure ensures that no damage or discoloration occurs.

- Q: How many steps do I need for stamping the stainless steel plate?

- The shape of the product determines how many processes are required. Even the simplest needs 1 processes, and the complex may take 7-8 steps to complete.

- Q: Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs. Stainless steel is a versatile material that can be etched using various methods such as chemical etching or laser engraving. Chemical etching involves applying a corrosive substance to the surface of the stainless steel, which selectively removes the unprotected areas and leaves the design etched onto the sheet. Laser engraving, on the other hand, uses a high-powered laser beam to etch the design onto the stainless steel surface. Both methods can achieve intricate and detailed designs on stainless steel sheets, making it a popular choice for decorative and functional applications in various industries.

Send your message to us

Supply 4x8 430 Stainless Steel Sheet in Wuxi

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords