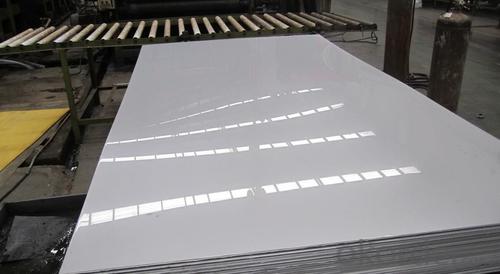

Stainless Steel sheet with shine polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the pricing options for stainless steel sheets?

- The pricing of stainless steel sheets can vary depending on a range of factors. First and foremost, the grade of stainless steel used plays a significant role. Stainless steel is available in various grades, each offering different levels of corrosion resistance and durability. Higher-grade stainless steel sheets generally come at a higher price. Another factor that influences pricing is the thickness and size of the sheets. Thicker and larger stainless steel sheets tend to be more expensive due to the increased amount of raw material required and the additional processing involved. Moreover, the finish of the stainless steel sheets can also impact the pricing. Different finishes, such as brushed, mirror, or matte, are available for stainless steel sheets. Finishes that necessitate more extensive processing and polishing may come at a higher cost. Additionally, market conditions, including the supply and demand for stainless steel, can affect pricing. Prices can fluctuate based on factors such as raw material costs, production capacity, and global economic conditions. Furthermore, it is crucial to consider the supplier or manufacturer from whom you are purchasing the stainless steel sheets. Different suppliers may offer varying pricing options based on their overhead costs, production capabilities, and market positioning. To summarize, the pricing options for stainless steel sheets are influenced by factors such as grade, thickness, size, finish, market conditions, and the supplier. It is advisable to conduct thorough research and compare prices from different sources to find the most suitable option for your specific requirements.

- Q: Can stainless steel sheets be used for decorative backsplashes?

- Yes, stainless steel sheets can be used for decorative backsplashes. Stainless steel is a versatile and durable material that is commonly used in kitchen and interior design. It offers a sleek and modern look, making it a popular choice for contemporary and industrial-style kitchens. Stainless steel backsplashes are not only visually appealing but also highly functional, as they are resistant to heat, stains, and water. Moreover, stainless steel is easy to clean and maintain, making it a practical option for a backsplash in a busy kitchen. Whether you prefer a polished, brushed, or patterned finish, stainless steel sheets can be customized to suit your aesthetic preferences, allowing you to create a stylish and eye-catching backsplash that complements your overall design scheme.

- Q: Are stainless steel sheets suitable for structural applications?

- Yes, stainless steel sheets are suitable for structural applications. Stainless steel has excellent strength, durability, and corrosion resistance properties, making it a reliable choice for various structural projects. It can withstand high loads and extreme weather conditions, making it suitable for applications such as bridges, buildings, and infrastructure projects.

- Q: Are stainless steel sheets suitable for desalination plants?

- Indeed, desalination plants find stainless steel sheets to be quite appropriate. Stainless steel exhibits remarkable resistance against corrosion and can endure the severe circumstances encountered in such plants, such as contact with saltwater and exposure to high temperatures. Its exceptional durability and mechanical characteristics render it an ideal material for multiple components in desalination plants, such as piping, heat exchangers, and tanks. Furthermore, stainless steel possesses commendable hygiene properties, rendering it suitable for desalination plants that necessitate stringent cleanliness standards. Moreover, the fabrication and installation of stainless steel sheets are effortless, allowing for efficient construction and maintenance procedures in desalination plants.

- Q: How to clean stainless steel plate cleaning?

- If ordinary water leaves some dirt or grease, try adding a mild detergent to the water. The method I used was derived from natural, biodegradable detergent and found that it removed a little water and missed it, including some oils. If you clean stainless steel pots or cutlery, this is the best way to use them. The food on the cooked food can usually be removed from the pan, soaked in soapy water, and with a mild sponge sponge pad. Don't be impatient to use steel wool, it may scratch stainless steel or leave particles that may rust. Again, remember to rinse and dry the stainless steel after cleaning.

- Q: What are the different types of stainless steel sheet finishes for pharmaceutical applications?

- Some of the different types of stainless steel sheet finishes for pharmaceutical applications include 2B finish, 2D finish, BA finish, and mirror finish.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Yes, stainless steel sheets are generally resistant to chemicals and acids due to the protective layer of chromium oxide that forms on their surface, which prevents corrosion and damage.

- Q: Inspection method for stainless steel welding

- The base material is square, and the appearance surface is not allowed to have defects such as pits, hemp spots, scratches and indentations.5) containers must be loaded with water to test for leaks6) appearance requirements refer to stainless steel appearance inspection standard

- Q: Can stainless steel sheets be used for heat shields?

- Yes, stainless steel sheets can be used for heat shields. Stainless steel is known for its high heat resistance and durability, making it an excellent choice for protecting against heat transfer. Stainless steel sheets can effectively shield against radiant heat, convective heat, and conductive heat, making them suitable for a variety of applications such as automotive heat shields, industrial equipment, and home appliances. Additionally, stainless steel sheets offer corrosion resistance and are easy to clean, making them a practical and long-lasting choice for heat shield applications.

- Q: Can stainless steel sheets be used for elevator cabins?

- Indeed, elevator cabins can utilize stainless steel sheets. The employment of stainless steel in elevator cabins is widespread owing to its resilience, pleasing aesthetics, and effortless upkeep. Its resistance to corrosion proves crucial in settings subjected to elevated humidity or chemical exposure. By utilizing stainless steel sheets, one can fashion elegant and contemporary elevator cabins that possess both functionality and visual allure. Furthermore, stainless steel's effortless cleaning and maintenance render it an exemplary selection for heavily frequented spaces like elevators.

Send your message to us

Stainless Steel sheet with shine polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords