Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Guidelines

Structure of product description:

What is the product?

High Quality Structural Carbon Steel H Beam

OKorder is proud to be offering hot rolled High Quality Structural Carbon Steel H Beams. Our Steel Beams meet all GB, JIS, and ASTM ST standards; available in Q235, Q345, SS400, S235JR, S275JR, S355JR grades. We are able to meet all client requirements as well as offer standard sizes of 5.8-12m - all either painted, galvanized or punch holed.

What is the intended use of the product?

The intended use of High Quality Structural Carbon Steel H Beam

Our H Beams are ideal for:

Construction support beams for commercial and residential construction

Mezzanines and platforms

Bridges

Trailer and truck bed framing

Machine bases

What is the product’s advantage?

The advantage of High Quality Structural Carbon Steel H Beam

OKorder is able to quickly ship orders within 20 days of receiving a deposit or original L/C. All products are shipped with ISO, SGS, BV, and CIQ certification as well as additional standards.

Main features of the product

Main features of High Quality Structural Carbon Steel H Beams

- ISO, SGS, BV and CIQ Certified

- Custom Sizes Available

- Shipped within 20 Days

FAQ:

- 3 FAQ’s minimum per product (use of single and phrase keywords in the question and answer of the FAQ’s)

Q1: Why you buy Materials & Equipment from OKorder.com ?

A: All products on OKorder.com are carefully selected from China's quality manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and commitment toward supply chain safety and customer satisfaction.

Q2: What is Carbon Steel ?

A: Modern steels are made with varying combinations of alloy metals to fulfill many purposes. Carbon steel, composed simply of iron and carbon, accounts for 90% of steel production.

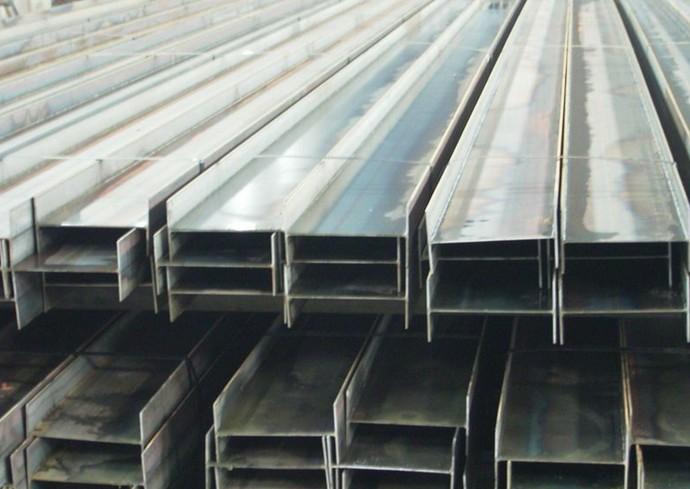

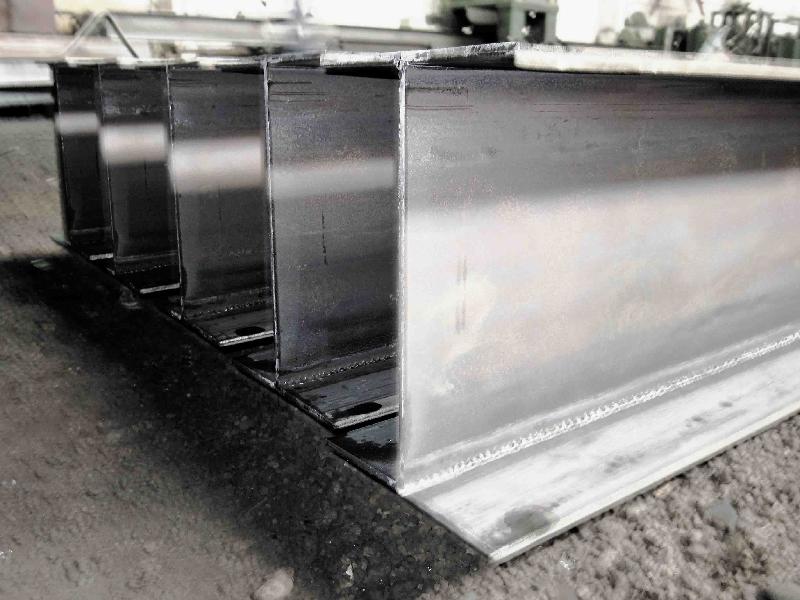

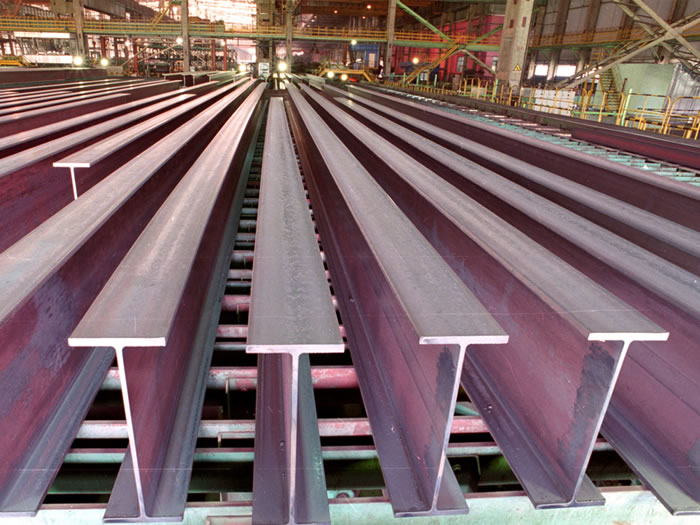

Images:

Specifications:

Specifications of High Quality Structural Carbon Steel H Beam

Place of Origin: | China (Mainland) | Grade: | SS400 | Technique: | Hot Rolled |

Application: | building,construction | Length: | 6-12m | Standard: | JIS |

Flange Width: | 50-300mm | Flange Thickness: | 5-16mm | Web Width: | 100-900MM |

Web Thickness: | 7-28MM | Brand Name: | NBSTEEL | Model Number: | 100*50*5*7-900*30*16*28 |

Standard: GB, JIS, ASTM ST

Material: Q235, Q345, SS400, S235JR, S275JR, S355JR

Length: 5.8-12m or according to our clients' requirements

Origin: Tangshan, China

Package: load on 20 feet/40 feet container or by bulk according to the quantity and our client's requirement

Delivery time: within 20 days after receiving deposit or original L/C

Certificate: ISO, SGS, BV, CIQ or other test

Technic: Hot rolled

Surface: painted, galvanized or punch holes

Main market: East-south Asia, Mid-east, South American

Usage: Construction structure and Frame use

Other Main products: Angle steel, I beam and Channel steel

Images:

- Q: How do steel I-beams compare to timber beams in terms of strength and durability?

- Steel I-beams are generally considered to be stronger and more durable than timber beams. Steel has a much higher strength-to-weight ratio than timber, meaning it can support heavier loads without bending or breaking. Additionally, steel is not susceptible to rot, insects, or fire like timber, which enhances its durability. Overall, steel I-beams are the preferred choice for structural applications where strength and long-term durability are crucial.

- Q: Can steel I-beams be used in data centers or tech facilities?

- Yes, steel I-beams can be used in data centers or tech facilities. Steel I-beams are commonly used in construction due to their strength and load-bearing capabilities. In data centers and tech facilities, where heavy equipment such as servers, networking equipment, and cooling systems are installed, steel I-beams provide the necessary structural support. They can withstand the weight of the equipment and help distribute the load evenly, ensuring the stability and safety of the facility. Additionally, steel I-beams are durable, fire-resistant, and resistant to pests, making them ideal for use in these types of facilities.

- Q: Can steel I-beams be used in power plants?

- Indeed, power plants make use of steel I-beams. These beams are frequently employed in power plants to fulfill a range of functions, including the support of heavy machinery, providing structural stability for buildings and equipment, and constructing robust frameworks for power plant structures. The exceptional strength and capacity to bear heavy loads of steel I-beams render them perfectly suited for enduring the immense loads and unforgiving conditions typically encountered in power plants. Furthermore, steel I-beams are adaptable and can be tailored to meet precise design criteria, rendering them a highly favored option in the construction and upkeep of power plants.

- Q: Can steel I-beams be used in hotels or hospitality buildings?

- Hotels and hospitality buildings can indeed make use of steel I-beams. These beams are widely used in the construction industry due to their remarkable strength and durability. They offer exceptional structural support, making them highly suitable for large-scale structures like hotels. Steel I-beams have the capacity to bear heavy loads and span long distances, allowing for the creation of flexible and spacious floor plans commonly found in hotels. Moreover, steel is resistant to fire, pests, and rot, making it a reliable and secure choice for construction. By incorporating steel I-beams into hotels and hospitality buildings, one can ensure the safety and longevity of the structure while also facilitating various architectural designs.

- Q: What are the maintenance requirements for steel I-beams?

- The maintenance requirements for steel I-beams primarily involve regular inspections, cleaning, and addressing any signs of corrosion or damage. Inspections should be conducted periodically to check for any signs of wear, cracking, or deformation in the beams. This can be done visually or with the assistance of non-destructive testing methods such as ultrasonic or magnetic particle inspection techniques. Cleaning the steel I-beams is essential to remove any dirt, debris, or contaminants that may have accumulated on the surface. This can be done using a mild detergent or a specialized cleaning solution, followed by rinsing with water and drying thoroughly. It is important to avoid using abrasive materials or cleaning agents that may damage the surface of the beams. Corrosion is a common concern for steel structures, and it is crucial to address any signs of rust or corrosion promptly. Rust can be removed using wire brushes or sandpaper, and the affected area can be treated with anti-corrosion coatings or paint to prevent further deterioration. Regular maintenance also includes checking any connections or fasteners used in the assembly of the I-beams. These should be inspected for tightness and replaced if they show signs of wear or corrosion. Additionally, maintaining a suitable environment for the steel I-beams is crucial. This involves keeping the beams away from moisture, excessive heat, or corrosive substances that can accelerate corrosion or weaken the structural integrity. Overall, by conducting regular inspections, cleaning, and addressing any signs of damage or corrosion, the maintenance requirements for steel I-beams can be effectively met, ensuring their longevity and optimal performance.

- Q: How do steel I-beams perform in terms of electromagnetic interference (EMI) shielding?

- Despite their strength and durability, steel I-beams fall short in providing substantial protection against electromagnetic interference (EMI). This is due to the fact that steel, being a proficient conductor of electricity, has the tendency to amplify electromagnetic fields instead of impeding them. Consequently, steel I-beams do not prove effective in mitigating the impact of electromagnetic interference.

- Q: How are steel I-beams installed in construction projects?

- Steel I-beams are installed in construction projects by first preparing the foundation to ensure it can support the weight of the beams. The I-beams are then hoisted into position using cranes or other heavy machinery. They are aligned and secured to the foundation or supporting structures using bolts, welding, or other appropriate methods. This installation process ensures the I-beams provide structural integrity and support for the building or structure.

- Q: Are steel I-beams affected by vibrations?

- Yes, steel I-beams can be affected by vibrations. Vibrations can cause the beams to resonate, leading to fatigue and potential failure over time. It is important to consider the frequency, amplitude, and duration of vibrations when designing structures with steel I-beams to ensure their stability and durability.

- Q: What is the difference between 18# GB and GB?

- The national standard refers to the approval issued by the national standardization administrative body, which is of great significance to the national economic and Technological Development and is unified throughout the country.

- Q: Cantilever scaffold of the I-beam, in the Yang Kok position encountered a frame column, what should I do?

- The frame column can be passed through, and the prefabricated formwork box is needed, and the I-beam can be drawn out later.

Send your message to us

Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords