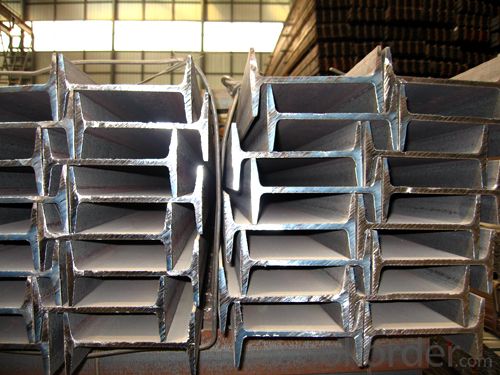

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Structural Steel I-Beam

OKorder is offering High Quality Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q235B, SM490, SS400, Q235B, Q345, Q345B

Production Process: Rolling cross-section

Dimensions:

Leg Height: 46 – 220mm

Depth: 50 – 180mm

Thickness: 4.5 – 17mm

Length: 6m – 12m

Production: 500 tons/month

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: The difference between I-beam and wide flange I-beam

- The ordinary I-beam is the I series. The difference between them is the width of the flange, the height and thickness of the web.Steel is generally Q235 steel.

- Q: Can steel I-beams be used for distribution centers?

- Indeed, distribution centers can make use of steel I-beams. These beams are frequently employed in construction as a result of their robustness and resilience. They possess exceptional load-bearing capabilities, which renders them suitable for accommodating substantial quantities of goods, machinery, and equipment that are typical of large-scale structures like distribution centers. Furthermore, steel I-beams can be tailored to different dimensions and lengths, thereby enabling flexibility in the design and arrangement of a distribution center's layout and structure. The utilization of steel I-beams in distribution centers guarantees a solid and dependable infrastructure that is capable of withstanding the demands imposed by storage, transportation, and logistics operations.

- Q: How long do steel I-beams typically last before needing replacement or maintenance?

- Steel I-beams typically last for several decades before needing replacement or maintenance. The exact lifespan depends on various factors such as the quality of the steel, the environmental conditions, and the level of maintenance and care provided. With proper maintenance and regular inspections, steel I-beams can last 50 years or more.

- Q: Are steel I-beams suitable for supporting rooftop gardens with water features?

- Depending on several factors, rooftop gardens with water features can potentially be supported by steel I-beams. The strength and load-bearing capabilities of steel I-beams are well-known, making them a popular choice for structural support in construction projects. When assessing the suitability of steel I-beams for supporting rooftop gardens with water features, it is crucial to consider the weight and load distribution of the garden and water features. This includes evaluating the weight of the soil, plants, water reservoirs, and any additional structures like ponds or fountains. Steel I-beams are specifically designed to withstand heavy loads, and by employing proper engineering and calculations, they can be appropriately sized and positioned to support the weight of a rooftop garden with water features. However, it is imperative to seek the guidance of a structural engineer or a qualified professional to ensure the steel I-beams are designed and installed correctly to meet the specific requirements of the rooftop garden. Various factors, such as the size and span of the I-beams, the distance between supports, and the overall structural integrity of the building, must all be taken into account. Additionally, the potential for water leakage or excess moisture should be evaluated to prevent any potential harm to the steel beams. Furthermore, regularly maintaining and inspecting the steel I-beams is crucial to ensure their ongoing suitability for supporting rooftop gardens with water features. Regular checks for signs of corrosion, instability, or any structural issues should be conducted to uphold the safety and stability of the rooftop garden. In conclusion, steel I-beams can potentially be suitable for supporting rooftop gardens with water features. However, consulting with a structural engineer or a qualified professional is vital to guarantee proper design, installation, and maintenance, thereby ensuring the safety and stability of the structure.

- Q: No. 20 I-beam, span 9 meters, can support the concrete roof?

- 1mm floor slab, top 10mm concrete? The board is too thin. Will there be anything else on the concrete? Without calculation, experience alone can not bear it.

- Q: Can steel I-beams be used in industrial facilities?

- Yes, steel I-beams can be used in industrial facilities. Steel I-beams are commonly used in the construction of industrial buildings and facilities due to their strength, durability, and versatility. They are capable of supporting heavy loads and providing structural stability, making them ideal for industrial applications where large machinery, equipment, and materials need to be supported. Additionally, steel I-beams can be easily fabricated and customized to meet the specific needs and requirements of an industrial facility, making them a popular choice in the construction industry.

- Q: What are the common methods for protecting steel I-beams from corrosion?

- Some common methods for protecting steel I-beams from corrosion include applying paint or coatings, using galvanization or hot-dip galvanizing, and utilizing cathodic protection systems.

- Q: Can steel I-beams be used in educational or institutional buildings?

- Certainly, educational or institutional buildings can indeed utilize steel I-beams. Due to their strength, durability, and versatility, steel I-beams are widely employed in construction. They offer structural support and have the capacity to bear heavy loads, rendering them perfect for extensive buildings. Furthermore, steel I-beams possess fire, pest, and rot resistance, guaranteeing the safety and longevity of the structure. Their flexibility also permits the creation of open floor plans and broad spans, features often sought after in educational or institutional settings. All in all, steel I-beams are a favored option in the construction industry and can certainly find use in educational or institutional buildings.

- Q: Can steel I-beams be used for theater stage supports?

- Yes, steel I-beams can be used for theater stage supports. They are commonly used in the construction of theater stages due to their strength, durability, and ability to support heavy loads.

- Q: How do steel I-beams compare to other structural materials, such as wood or concrete?

- Steel I-beams possess numerous advantages over alternative structural materials like wood or concrete. To begin with, steel exhibits immense strength and a high strength-to-weight ratio, enabling it to support larger loads with significantly less material compared to wood or concrete. Consequently, steel I-beams are an exceptional choice for structures necessitating high load-bearing capacity. Moreover, steel I-beams boast exceptional durability and resistance to various forms of wear and tear. Unlike wood, steel is impervious to rotting, warping, or insect infestation, guaranteeing a longer lifespan for the structure. Additionally, steel can withstand extreme weather conditions, rendering it suitable for structures in areas prone to earthquakes, hurricanes, or heavy snow loads. Regarding construction, steel I-beams offer increased versatility and ease of installation. They can be prefabricated off-site, allowing for faster and more efficient construction. Furthermore, steel beams can span longer distances without requiring additional support columns, providing greater flexibility in design and layout. Another advantage of steel I-beams lies in their fire resistance. Steel does not burn or contribute to the spread of fire, making it a safer choice in comparison to wood. In contrast, wood is a combustible material that can ignite rapidly and result in structural collapse. Nevertheless, it is crucial to consider the cost factor. Generally, steel is more expensive than wood or concrete, thereby making it less economical for smaller-scale projects or areas with limited budgets. Additionally, insulating steel I-beams can prove more challenging than insulating wood or concrete, potentially leading to higher heating or cooling costs. In conclusion, steel I-beams represent a superior option for structures requiring strength, durability, and fire resistance. Although they may entail higher upfront costs, their long-term benefits render them the preferred choice for large-scale commercial buildings, bridges, and industrial structures.

Send your message to us

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords