high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

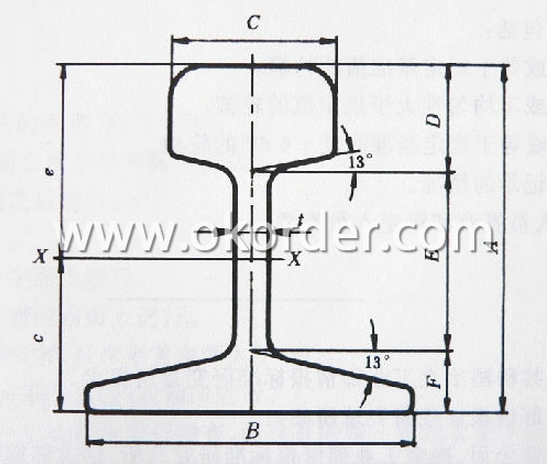

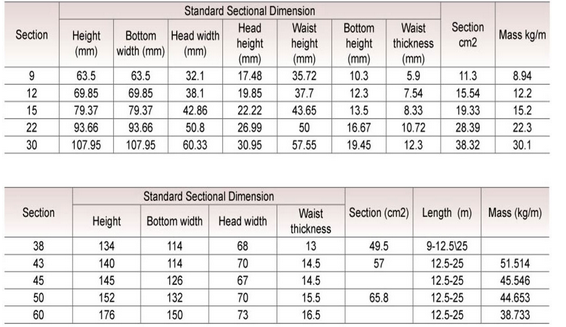

Specifications of Ms Steel Rail

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: 55Q

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Ms Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Ms Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Ms Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How do steel rails contribute to the efficiency of railway systems?

- There are several ways in which steel rails contribute to the efficiency of railway systems. Firstly, steel is a very strong and durable material, allowing the rails to withstand heavy loads and constant wear and tear. This means that they can last for many years without requiring frequent replacement or repair, reducing maintenance costs and downtime. Secondly, the design of steel rails ensures that trains have a smooth and stable surface to travel on. The evenness of the rails helps to minimize vibrations and reduce friction between the wheels and the track, resulting in less energy being needed to propel the train forward. This not only improves the overall energy efficiency of the railway system but also enables trains to reach higher speeds, reducing travel times and increasing capacity. Additionally, steel rails are engineered with precise dimensions and alignment, ensuring safe and smooth travel for trains. This accuracy helps to prevent derailments and maintain train stability, enhancing the overall safety and reliability of the railway system. Moreover, steel rails are compatible with various signaling and control systems, allowing for efficient and precise train operation. These systems rely on the accurate positioning of trains on the tracks, which is facilitated by the consistent and well-maintained steel rails. Lastly, steel rails offer excellent resistance to corrosion, which is particularly important in areas with harsh weather conditions or exposure to moisture. The durability and resistance to corrosion of steel rails greatly reduce the need for frequent replacements, resulting in cost savings and improved efficiency for railway systems. In conclusion, steel rails play a crucial role in enhancing the efficiency of railway systems through their strength, durability, smoothness, precision, and resistance to corrosion. Their numerous advantages contribute to safer, faster, and more reliable train travel, ultimately improving the overall performance and effectiveness of railway systems.

- Q: What are the environmental benefits of using steel rails in transportation?

- The environmental benefits of using steel rails in transportation include lower energy consumption, reduced greenhouse gas emissions, and decreased land degradation. Steel rails provide a more efficient and sustainable mode of transportation compared to other alternatives, making them a greener choice for the environment.

- Q: How do steel rails contribute to train speed maintenance?

- Steel rails contribute to train speed maintenance in several ways. Firstly, steel rails provide a smooth and stable surface for the train to run on, reducing friction and allowing for efficient movement. This helps the train maintain a constant speed and minimizes energy loss. Additionally, steel rails are designed to withstand heavy loads and provide structural support, ensuring the train remains on track and stable at high speeds. The durability of steel rails also minimizes wear and tear, reducing the need for frequent maintenance and allowing trains to operate at optimal speed.

- Q: What is the maximum speed that steel rails can handle?

- The maximum speed that steel rails can handle depends on various factors such as the quality of the rail material, maintenance practices, and the design of the track. Generally, steel rails can handle speeds ranging from 80 to 125 miles per hour (130 to 200 kilometers per hour) for conventional rail lines. However, for high-speed rail systems, specially designed tracks and rails can support speeds of up to 186 miles per hour (300 kilometers per hour) or even higher.

- Q: How are steel rails protected from natural disasters?

- Steel rails are protected from natural disasters through various measures such as regular inspections, maintenance, and reinforcement of infrastructure. Additionally, advanced warning systems and emergency response plans are in place to minimize the impact of natural disasters on railways.

- Q: What is the impact of steel rails on train fuel efficiency?

- The positive impact of steel rails on train fuel efficiency cannot be underestimated. Steel rails play a crucial role in providing a smooth and stable surface for the train wheels to roll on, resulting in reduced friction and resistance. Consequently, trains are able to operate more efficiently and achieve higher speeds. This reduced friction between the steel rails and train wheels leads to decreased energy wastage, ultimately resulting in lower fuel consumption. When compared to other materials such as wooden or concrete rails, steel rails exhibit superior durability and strength. They possess the ability to withstand heavy loads and maintain their shape and integrity over long distances and extended periods of time. This durability ensures that the train stays on a stable track, minimizing the need for frequent repairs or adjustments. As a result, the train is able to maintain its momentum and consume less fuel in the process. Additionally, steel rails have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with temperature changes. This characteristic allows for a more consistent and reliable track alignment, reducing the need for constant realignment and maintenance. The stable track alignment ensures that the train can travel efficiently without unnecessary energy losses due to misalignment or track irregularities. Moreover, steel rails contribute to the overall safety and reliability of train transportation. Their strength and durability help prevent derailments and accidents, thereby ensuring the safety of passengers and cargo. Furthermore, by providing a stable and secure track, steel rails minimize the risk of train delays and disruptions, enhancing the reliability and punctuality of train services. In conclusion, the impact of steel rails on train fuel efficiency is undeniably positive. The smooth and stable surface they provide reduces friction and resistance, resulting in improved fuel efficiency. The durability of steel rails ensures a consistent track alignment, reducing the need for repairs and maintenance and further optimizing fuel efficiency. Overall, steel rails contribute to safer, more reliable, and environmentally friendly train transportation.

- Q: How are steel rails protected against track settlement?

- Various methods are employed to protect steel rails against track settlement. One commonly used approach involves the implementation of ballast, which consists of crushed stones or gravel that is placed beneath and around the rails. By offering stability and evenly distributing the weight of the trains, ballast prevents excessive settlement. To further safeguard against settlement, the rails themselves are designed to be sturdy and long-lasting, with appropriate spacing and alignment. This design ensures that the weight of the trains is evenly distributed along the entire length of the rails, thus minimizing the chances of settlement. Regular inspections and maintenance are also conducted to identify any signs of settlement or deformation. In certain instances, engineers may employ additional techniques such as under-sleeper pads or resilient fasteners to enhance protection against settlement. Under-sleeper pads are made of rubber or polyurethane and are placed between the rail and the sleeper. These pads help absorb vibrations and reduce the impact of settlement. On the other hand, resilient fasteners are specifically designed to allow some movement of the rail, compensating for settlement and reducing stress on the track structure. Overall, a combination of proper design, regular maintenance, and the use of ballast, under-sleeper pads, and resilient fasteners effectively safeguard steel rails against track settlement. These measures are crucial for maintaining the safety and stability of the tracks, reducing the risk of derailments, and ensuring smooth and efficient rail operations.

- Q: What are the safety measures for workers during steel rail installation?

- When it comes to steel rail installation, ensuring the safety of workers is of utmost importance. Here are some key safety measures that should be followed: 1. Personal Protective Equipment (PPE): Workers should be provided with and required to wear appropriate PPE, including helmets, safety goggles, gloves, steel-toed boots, and high-visibility vests. This will protect them from potential head injuries, eye injuries, hand injuries, and slips, trips, and falls. 2. Training and Education: Workers should receive proper training on steel rail installation techniques and safety protocols before starting work. This should include instruction on how to handle heavy equipment, use tools correctly, and identify potential hazards. 3. Safe Lifting Techniques: Train workers on proper lifting techniques to prevent strains and other musculoskeletal injuries. Encourage the use of mechanical aids, such as cranes or forklifts, to lift and move heavy rail sections. 4. Clear Communication: Establish clear communication channels among workers and supervisors to ensure everyone is aware of their roles and responsibilities. This includes using hand signals, radios, or other communication devices to maintain constant contact and share information about any potential hazards. 5. Site Inspection and Hazard Identification: Regularly inspect the worksite to identify potential hazards or unsafe conditions. Address any issues promptly to prevent accidents or injuries. 6. Fall Protection Measures: Install guardrails, safety nets, or other fall protection systems when working at heights. Ensure workers are properly trained in using fall arrest systems and that they are regularly inspected and maintained. 7. Equipment Maintenance: Regularly inspect and maintain all equipment used during steel rail installation to ensure proper functioning. Faulty or damaged equipment should be immediately repaired or replaced to prevent accidents. 8. Traffic Control: If the installation is taking place near roadways or in public areas, establish proper traffic control measures to ensure the safety of workers and the general public. Use cones, signs, and barriers to direct traffic and create a safe work zone. 9. Emergency Procedures: Develop and communicate emergency procedures, including evacuation plans, in case of accidents, fires, or other emergencies. Ensure all workers are aware of these procedures and conduct regular drills to practice them. 10. Supervision and Monitoring: Assign competent supervisors to oversee the steel rail installation process and ensure that safety measures are being followed. Regularly monitor the worksite to identify any potential safety hazards or non-compliance with safety protocols. By implementing these safety measures, the risk of accidents, injuries, and fatalities during steel rail installation can be significantly reduced, creating a safer working environment for all workers involved.

- Q: What are the challenges of maintaining steel rails in remote areas?

- Maintaining steel rails in remote areas poses several challenges that need to be addressed to ensure the smooth functioning of railways. 1. Accessibility: One of the primary challenges is the remote location itself. Often, remote areas lack proper infrastructure such as roads or transportation systems, making it difficult to reach the rail tracks. The absence of nearby maintenance facilities and limited transport options for repair equipment and materials can hinder timely maintenance operations. 2. Extreme weather conditions: Remote areas are often subject to harsh climates, including extreme temperatures, heavy rainfall, snowfall, or desert conditions. These weather conditions can lead to corrosion, erosion, and damage to the steel rails. Frequent inspections and repairs are required to prevent accidents and ensure safe and reliable train operations. 3. Wildlife interference: Remote areas are often home to diverse wildlife populations. Animals like deer, bears, or even smaller creatures may cross the tracks, potentially causing accidents. Ensuring the safety of both the animals and the trains becomes a significant challenge, requiring the implementation of measures such as wildlife crossings, fencing, or deterrents. 4. Limited resources and expertise: Remote areas typically have limited resources and a smaller pool of skilled workers. Maintenance crews may have to travel long distances to reach these areas, leading to increased costs and logistical challenges. Additionally, finding personnel with specialized knowledge and experience in maintaining steel rails can be a challenge, further complicating maintenance efforts. 5. Communication infrastructure: Remote areas often lack adequate communication infrastructure, which is crucial for effective maintenance operations. Communication is vital for quick reporting of issues, coordination between maintenance crews, and real-time monitoring of the rail tracks. Implementing reliable communication systems in remote areas can be costly and technically challenging. 6. Cost implications: Maintaining steel rails in remote areas can be more expensive than in urban or well-connected regions. The costs associated with transportation, accommodation, and acquiring specialized equipment can significantly add to the overall maintenance expenses. Limited financial resources in remote areas can further strain the budget allocated for rail maintenance. Addressing these challenges requires a comprehensive approach, including investment in infrastructure development, training and recruitment of skilled personnel, improved communication systems, and the implementation of preventive maintenance strategies. By overcoming these challenges, remote areas can ensure the safe and efficient operation of rail transport, supporting local communities and economic development.

- Q: What are the specifications for steel rails used in high-speed rail networks?

- The specifications for steel rails used in high-speed rail networks typically include requirements such as high strength, durability, and resistance to wear and fatigue. They are usually made of high-quality steel, with specific chemical composition and mechanical properties, to ensure their ability to withstand heavy loads and frequent use. Furthermore, these rails often have precise dimensions and strict tolerances to guarantee smooth alignment and minimize vibrations, allowing for safe and efficient high-speed train operations.

Send your message to us

high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords