Steel Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

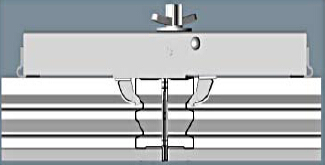

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

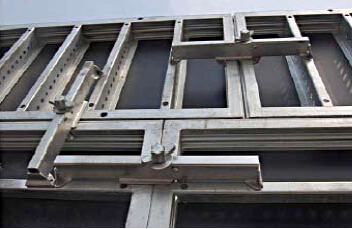

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle formwork removal and storage?

- Steel formwork is known for its durability and strength, which makes it highly suitable for handling formwork removal and storage. When it comes to formwork removal, steel formwork can be easily disassembled and removed from the concrete structure. This is primarily due to the modular nature of steel formwork, which allows for easy dismantling and reassembly. Steel formwork systems often consist of standard-sized panels that can be quickly and efficiently removed by loosening the connecting bolts or clips. This process ensures that the formwork can be easily dismantled without causing damage to the concrete structure or the formwork itself. Additionally, the lightweight nature of steel formwork allows for easy handling during removal, reducing the risk of accidents or injuries. In terms of storage, steel formwork offers several advantages. Firstly, steel formwork can be stacked and stored in a compact manner, saving space in construction sites or storage facilities. The modular design of steel formwork panels allows for easy stacking and organization, ensuring that the formwork can be efficiently stored without taking up excessive space. Furthermore, steel formwork is less susceptible to damage from weather conditions compared to other types of formwork materials such as wood or plywood. Steel formwork can withstand exposure to rain, sunlight, and temperature fluctuations without warping, rotting, or deteriorating. This durability makes steel formwork a reliable option for long-term storage, as it can be reused multiple times without significant degradation. Overall, steel formwork provides a superior solution for formwork removal and storage. Its strength and durability allow for easy dismantling and removal, while its modular design and compact storage capabilities make it an ideal choice for efficient storage. With these advantages, steel formwork contributes to increased productivity and cost-effectiveness in construction projects.

- Q: How does steel formwork handle concrete surface finishing?

- The construction industry favors steel formwork due to its durability, strength, and versatility. When it comes to finishing concrete surfaces, steel formwork offers numerous advantages. To start with, steel formwork guarantees a superior finish by providing a smooth and even surface. The rigid nature of steel prevents any warping or bending during the pouring and curing process, ensuring that the concrete maintains its desired shape and dimensions. Achieving a level and flat surface is crucial for various construction applications. Furthermore, steel formwork enables precise control over the concrete pouring process. The tight joints and strong connections in steel formwork prevent any leakage or seepage of the concrete, resulting in a clean and consistent surface finish. This is especially beneficial for projects that require a high degree of precision or have specific architectural requirements. Moreover, steel formwork allows for easy customization to create different surface finishes. Contractors can incorporate various textures, patterns, or coatings onto the steel panels, achieving a wide range of aesthetic effects on the concrete surface. This flexibility in design enhances the overall visual appeal of the finished structure. Lastly, steel formwork is cost-effective as it is reusable. Unlike other formwork materials like wood or plastic, steel formwork can be cleaned, repaired, and reused multiple times, reducing material waste and saving on construction costs. This sustainability aspect aligns with the increasing importance of environmentally friendly and economically viable approaches in the construction industry. In conclusion, steel formwork provides excellent support for finishing concrete surfaces. Its strength, precision, customization options, and reusability make it the preferred choice for achieving high-quality finishes in construction projects. Whether it is a smooth and level surface or an intricately textured design, steel formwork ensures that the concrete surface meets the desired specifications.

- Q: How does steel formwork compare to wooden formwork in terms of cost?

- Steel formwork generally tends to be more expensive than wooden formwork in terms of upfront costs. This is mainly due to the higher cost of materials and manufacturing processes involved in producing steel formwork. Additionally, steel formwork often requires specialized equipment and skilled labor for installation, which can further contribute to its higher cost. On the other hand, wooden formwork is typically more affordable in terms of initial investment. Wood is widely available and relatively inexpensive compared to steel. Furthermore, wooden formwork can be easily fabricated and customized on-site, reducing the need for additional expenses associated with specialized manufacturing. However, it is important to consider the long-term costs when comparing steel and wooden formwork. Steel formwork has the advantage of being more durable and resilient to wear and tear. It can withstand multiple uses and is less susceptible to damage from moisture, insects, and other environmental factors. This means that steel formwork can be used repeatedly, reducing the need for frequent replacement and lowering long-term costs. Wooden formwork, on the other hand, may require regular maintenance, repairs, and eventual replacement due to its susceptibility to damage and deterioration over time. This can result in additional costs over the lifespan of the project. In conclusion, while steel formwork may be initially more expensive than wooden formwork, its durability and longevity can lead to cost savings in the long run. However, the choice between steel and wooden formwork ultimately depends on the specific project requirements, budget, and other factors such as time constraints and availability of resources.

- Q: Can steel formwork be used in precast concrete applications?

- Yes, steel formwork can be used in precast concrete applications. Steel formwork is commonly used in precast concrete construction as it offers durability, strength, and the ability to create complex shapes and designs. It provides a reliable and efficient solution for creating precise and high-quality precast concrete elements.

- Q: How does steel formwork affect the overall sound insulation of a structure?

- Steel formwork has a significant impact on the overall sound insulation of a structure. Due to its dense and rigid nature, steel formwork tends to transmit sound vibrations more efficiently compared to other materials such as wood or plastic. This means that if steel formwork is used extensively in a building's construction, it can potentially reduce the sound insulation capabilities of the structure. The transmission of sound through steel formwork occurs mainly through three mechanisms: airborne sound, impact sound, and structure-borne sound. Airborne sound refers to sound waves traveling through the air and being transmitted through the steel formwork. Impact sound occurs when a sound wave hits the steel surface, causing it to vibrate and transmit the sound further. Structure-borne sound refers to vibrations traveling through the steel formwork and being transmitted to other parts of the building. To mitigate the negative impact of steel formwork on sound insulation, various measures can be taken. One approach is to use additional sound-absorbing materials, such as acoustic panels or insulation, on the interior surfaces of the structure. These materials can help reduce the transmission of airborne sound waves and dampen the vibrations caused by impact or structure-borne sound. Additionally, proper sealing and jointing of the formwork can minimize the leakage of sound through gaps or cracks. It is important to note that the overall sound insulation of a structure is not solely dependent on the formwork material. Other factors, such as the thickness of walls, type of insulation used, and the design of windows and doors, also play a crucial role. Therefore, while steel formwork may have a negative impact on sound insulation, it is possible to compensate for this by employing appropriate acoustic design strategies and incorporating soundproofing techniques throughout the building's construction process.

- Q: How does steel formwork handle formwork stability during concrete pouring?

- Steel formwork provides excellent formwork stability during concrete pouring due to its high strength and rigidity. It can withstand the pressure and weight of the fresh concrete without deformation or collapse, ensuring the desired shape and structure of the concrete elements. Additionally, steel formwork can be easily adjusted and secured in place, allowing for precise alignment and stability during the pouring process.

- Q: What are the different accessories required for steel formwork maintenance?

- The different accessories required for steel formwork maintenance include the following: 1. Formwork cleaning agents: These are used to remove any concrete residue or build-up on the steel formwork. They help in maintaining the smooth surface of the formwork and prevent any damage or corrosion. 2. Formwork release agents: These are applied to the steel formwork before pouring concrete to prevent it from sticking to the formwork. They help in easy removal of the formwork after the concrete has cured. 3. Formwork patching compounds: These are used to repair any damages or imperfections on the steel formwork. They help in maintaining the structural integrity of the formwork and ensure its longevity. 4. Formwork oil or grease: These lubricants are applied to the moving parts of the steel formwork, such as hinges or sliding mechanisms. They help in smooth operation and prevent any friction or wear and tear. 5. Formwork ties and connectors: These are used to secure the formwork panels together and ensure stability during concrete pouring. They should be regularly inspected and replaced if damaged or worn out. 6. Formwork wedges and pins: These are used to align and secure the formwork panels in place. They should be checked regularly to ensure proper positioning and stability. 7. Formwork clamps and brackets: These accessories are used to support and hold the formwork panels in position. They should be inspected for any signs of damage or weakness and replaced if necessary. 8. Formwork cleaning tools: These include brushes, scrapers, and high-pressure washers, which are used to clean the steel formwork. Regular cleaning helps in maintaining the formwork's appearance and prevents the accumulation of dirt or debris. 9. Formwork storage and transportation equipment: These include racks, trolleys, or storage containers, which are used to store and transport the steel formwork safely. Proper storage and transportation ensure the formwork's longevity and prevent any damage or distortion. Overall, the different accessories required for steel formwork maintenance are crucial to ensure the formwork's optimal performance, durability, and safety during concrete construction projects.

- Q: How does steel formwork handle formwork stripping and demolding?

- Steel formwork is known for its durability and strength, making it an excellent choice for handling formwork stripping and demolding. When it comes to the process of formwork stripping, steel formwork offers several advantages. Firstly, steel formwork is designed with a smooth surface, which allows for easy removal of the hardened concrete once it has cured. This smooth surface reduces the chances of concrete sticking to the formwork, making it easier to strip the formwork without causing any damage to the structure. Secondly, steel formwork is typically constructed with a system of joints and connections that facilitate efficient formwork stripping. These joints and connections are designed to be easily detachable, allowing for quick and straightforward removal of the formwork. This feature is particularly beneficial when working on large-scale construction projects where time is of the essence. Furthermore, steel formwork is highly resistant to deformation and warping, ensuring that the formwork remains in its original shape during the stripping process. This resistance to deformation helps to prevent any distortion or damage to the concrete structure during the demolding phase. In addition, steel formwork offers excellent reusability, which further contributes to its efficiency in handling formwork stripping and demolding. Once the formwork is stripped, it can be cleaned, repaired if necessary, and reused for subsequent concrete casting. This reusability not only saves time and money but also reduces the environmental impact associated with formwork disposal. Overall, steel formwork is designed to handle formwork stripping and demolding with ease. Its smooth surface, detachable joints, resistance to deformation, and reusability make it a reliable and efficient choice for construction projects.

- Q: How does steel formwork handle different concrete surface gloss levels?

- Steel formwork is a versatile option that is capable of accommodating different concrete surface gloss levels effectively. It provides a smooth and even surface for concrete placement, allowing the desired finish to be achieved. Additionally, steel formwork is durable and can withstand the pressures and forces exerted by the concrete, ensuring that the surface gloss remains consistent throughout the curing process.

- Q: How does steel formwork handle different concrete surface finishing options?

- Steel formwork is highly versatile and capable of accommodating various concrete surface finishing options with ease. Its robust structure provides excellent support, allowing for smooth finishes like polished concrete or exposed aggregate. Additionally, steel formwork can incorporate intricate patterns or textures, enabling decorative finishes such as stamped or stenciled concrete. Moreover, the durability of steel formwork ensures consistent and accurate results, regardless of the desired surface finishing option.

Send your message to us

Steel Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords