Steel-Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

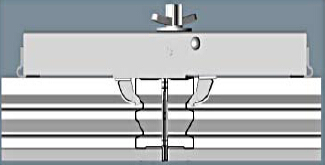

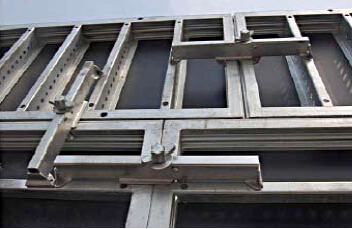

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle concrete bleeding?

- Steel formwork is an excellent choice for handling concrete bleeding. Concrete bleeding refers to the process where water in the concrete mixture rises to the surface, resulting in the separation of the water from the solid components. Steel formwork is designed to have a smooth and non-porous surface, which helps to prevent excessive bleeding and the loss of water from the concrete mixture. The tight joints and connections of steel formwork also minimize the chances of water seepage, ensuring that the concrete retains its desired water content. Additionally, steel formwork provides excellent support and stability to the concrete during the pouring and setting process. This prevents the formation of voids or gaps within the concrete, reducing the risk of excessive bleeding. The rigidity of steel formwork also helps to maintain the shape and structure of the concrete, preventing any deformation or cracking that may occur due to bleeding. Moreover, steel formwork allows for easy and efficient removal of excess water from the concrete surface. The smooth and non-absorbent nature of steel formwork facilitates the use of various techniques, such as squeegeeing or vacuuming, to remove the excess water, reducing the bleeding effect. In summary, steel formwork handles concrete bleeding effectively by providing a smooth and non-porous surface, minimizing water seepage, ensuring stability and support to the concrete, and allowing for efficient removal of excess water.

- Q: What are the common design considerations for steel formwork in heritage buildings?

- Some common design considerations for steel formwork in heritage buildings include ensuring that the formwork is compatible with the existing architectural features and materials, preserving the historical integrity of the building, providing adequate structural support, and facilitating ease of installation and removal without causing damage to the heritage elements. Additionally, considerations for weather resistance, durability, and fire safety may also be important factors in the design process.

- Q: What are the different types of form ties used in steel formwork systems?

- In steel formwork systems, there exist various form ties that serve to establish a secure bond between the formwork panels and supporting structures. 1. Conventional Form Ties: The most commonly employed form ties are those comprised of a steel rod with cones or washers on both ends. These rods are inserted through the formwork panels and secured using nuts or wedges, resulting in a robust connection. 2. Coil Ties: These ties are constructed from a continuous loop of wire, often galvanized to resist corrosion. They are simple to install and remove, and can accommodate different concrete wall thicknesses by adjusting the loop length. 3. She-Bolts: Alternatively referred to as she-bolts or coil bolts, these form ties consist of a threaded rod embedded in the concrete wall, along with a plate and nut on the external side. They establish a sturdy connection and find common usage in scenarios where frequent formwork removal and repositioning is necessary. 4. Snap Ties: Equipped with a flat plate on one end and a snap-tie wedge on the other, these ties are easily and swiftly installed without any special tools. They offer a dependable connection and are suitable for light to medium-duty applications. 5. Plastic Cone Ties: Designed for use with reusable plastic formwork systems, these ties are made from plastic material. They possess a lightweight nature, are easy to handle, and exhibit excellent resistance to chemical corrosion. 6. Flat Ties: Strip or bar-shaped, flat ties are utilized to connect formwork panels. Typically crafted from steel, they can be readily bent or cut to the desired length. These ties are frequently employed in scenarios where the wall thickness is minimal. 7. Wedge Bolts: Comprising a threaded rod, a wedge-shaped plate, and a nut, these form ties are inserted into a hole in the formwork panel. Tightening the nut secures the connection. Wedge bolts are commonly employed in situations requiring high strength and rapid installation. These aforementioned examples merely represent a selection of the various form ties adopted within steel formwork systems. The choice of form tie is contingent upon factors such as the application, concrete wall thickness, desired strength, and ease of installation and removal.

- Q: Can steel formwork be used in high-rise construction?

- Yes, steel formwork can be used in high-rise construction. Steel formwork offers high strength and durability, making it suitable for withstanding the high pressures and loads experienced in tall buildings. It also provides excellent dimensional accuracy, allowing for precise construction and ensuring the structural integrity of the high-rise building. Furthermore, steel formwork can be easily assembled and disassembled, making it a time-efficient choice for large-scale projects.

- Q: Can steel formwork be used in high-rise construction projects?

- Yes, steel formwork can be used in high-rise construction projects. Steel formwork offers several advantages such as durability, strength, and the ability to withstand high concrete pressure. It provides a stable and efficient solution for constructing walls, slabs, and columns in high-rise buildings. Additionally, steel formwork can be easily customized and reused, making it a cost-effective choice for such projects.

- Q: How does steel formwork contribute to the quality of the concrete finish?

- The quality of the concrete finish is greatly influenced by the use of steel formwork. The primary role of steel formwork is to provide a sturdy and inflexible structure that holds the concrete in place while it is being poured and cured. This effectively prevents any movement or distortion of the concrete, resulting in a sleek and uniform surface. Furthermore, steel formwork offers superior dimensional stability compared to other materials used for formwork. It does not bend or alter under the pressure of the wet concrete, guaranteeing precise and consistent shapes and measurements. This is particularly crucial for structures that demand accurate dimensions, such as beams, columns, or walls. Additionally, steel formwork allows for better control over the final appearance of the concrete surface. The smooth and non-porous nature of steel minimizes the likelihood of air bubbles or voids forming on the surface, resulting in an aesthetically pleasing finish with fewer imperfections. Moreover, steel formwork exhibits exceptional resistance to moisture and chemicals found in the concrete mixture. This prevents any damage or deterioration of the formwork itself, ensuring a clean and unblemished concrete surface. It also enables easy removal of the formwork once the concrete has cured, leaving no residues or marks behind. Lastly, the reusability of steel formwork makes it a cost-effective and sustainable choice. By being able to reuse the same set of formwork multiple times, consistent quality is achieved in subsequent concrete pours. This eliminates the need for frequent investments in new formwork materials, reducing overall project costs and environmental impact. In conclusion, the use of steel formwork is vital for achieving a high-quality concrete finish. Its strength, dimensional stability, control over surface finish, resistance to moisture and chemicals, and reusability all contribute to a smooth, accurate, and visually appealing surface while providing durability and cost-effectiveness to construction projects.

- Q: Can steel formwork be used for concrete walls and columns?

- Yes, steel formwork can be used for concrete walls and columns. Steel formwork is strong, durable, and can withstand the pressure exerted by the wet concrete. It offers a high level of accuracy and consistency in shaping the concrete structure. Additionally, steel formwork can be reused multiple times, making it a cost-effective choice for construction projects.

- Q: How does steel formwork contribute to the overall durability of a structure?

- There are several ways in which steel formwork enhances the overall durability of a structure. Firstly, its resistance to wear and tear allows it to withstand the heavy loads and pressures exerted during construction, preventing any deformations or damages. This ensures accurate construction and maintains the structure's integrity. Furthermore, steel formwork exhibits excellent dimensional stability, retaining its shape and size even under extreme conditions like high temperatures or moisture exposure. This stability ensures that the concrete poured into the formwork maintains its desired shape and structural strength, resulting in a more durable structure. Additionally, steel formwork offers superior strength and rigidity compared to other materials. This strength allows it to support heavy concrete loads without any deformation or collapse, ensuring the stability and security of the structure. This is particularly important for large-scale structures such as bridges or high-rise buildings, where the formwork must bear significant loads for extended periods. Moreover, steel formwork is highly resistant to corrosion, a common cause of deterioration in construction materials. This resistance protects the formwork from environmental factors like moisture or chemicals, enhancing the structure's overall durability by minimizing the risk of corrosion-related damages. Lastly, the reusability of steel formwork contributes to both the sustainability of the construction process and cost-effectiveness. By being able to reuse the formwork multiple times, the need for additional materials and resources is reduced, resulting in less waste and lower construction costs. Additionally, the ability to properly maintain and inspect the formwork before each reuse enhances its durability and longevity. In conclusion, steel formwork is crucial in enhancing the overall durability of a structure. Its resistance to wear and tear, dimensional stability, strength, corrosion resistance, and reusability all contribute to the construction of a strong and long-lasting structure, ensuring its integrity and minimizing the risk of structural failures or damages over time.

- Q: How does steel formwork contribute to the overall quality of the concrete finish?

- Steel formwork contributes to the overall quality of the concrete finish in several ways. Firstly, steel formwork provides a strong and rigid framework for the concrete to be poured into. This ensures that the concrete is poured in the desired shape and dimensions, resulting in a more accurate and precise finish. Unlike other types of formwork materials, such as wood or plastic, steel formwork does not warp or bend under the weight and pressure of the concrete. This prevents any deformations or imperfections in the final concrete surface. Secondly, steel formwork allows for smoother and more even concrete surfaces. The smooth surface of steel formwork prevents the formation of air pockets or voids in the concrete, resulting in a smoother finish. This is particularly important for concrete surfaces that will be exposed or visible, such as architectural elements or decorative finishes. Furthermore, steel formwork provides better support and stability during the pouring and setting process of the concrete. The rigid structure of steel formwork ensures that the concrete is properly contained and supported, reducing the risk of cracks or other structural issues. This helps to maintain the integrity and durability of the concrete finish over time. Additionally, steel formwork is highly durable and reusable. Unlike other types of formwork materials that may need to be replaced after a few uses, steel formwork can be used multiple times without compromising its quality. This not only reduces costs but also ensures consistent and high-quality concrete finishes throughout various construction projects. In conclusion, steel formwork plays a crucial role in achieving a high-quality concrete finish. Its strength, stability, and smooth surface contribute to the accuracy, precision, and durability of the final concrete surface. By providing a reliable and reusable framework, steel formwork helps to create consistent and aesthetically pleasing concrete finishes.

- Q: Can steel formwork be used in areas with limited construction equipment access?

- Indeed, areas with limited access to construction equipment can still utilize steel formwork. Renowned for its durability and strength, steel formwork proves ideal for remote or challenging locales. Differing from other formwork types, steel formwork does not necessitate extensive machinery or equipment during installation. Instead, it can be conveniently transported and manually assembled, diminishing the reliance on heavy machinery. Furthermore, steel formwork is reusable, allowing for disassembly and relocation to different sites, if needed. Such adaptability renders steel formwork a pragmatic option for construction endeavors in equipment-constrained areas, guaranteeing efficient and cost-effective construction procedures.

Send your message to us

Steel-Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords