Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

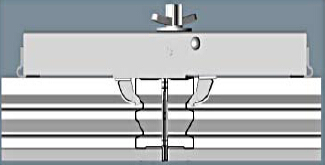

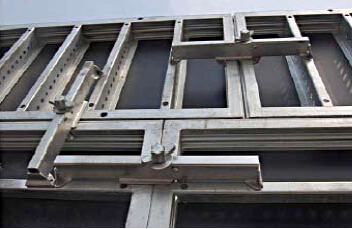

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used in areas with extreme temperature variations?

- Yes, steel formwork can be used in areas with extreme temperature variations. Steel has a high strength-to-weight ratio and is resistant to temperature changes, making it suitable for use in various conditions. It can withstand both high and low temperatures without structural deformation or deterioration. Additionally, steel formwork provides excellent stability and durability, ensuring that it can withstand the stress caused by extreme temperature fluctuations. However, it is important to consider thermal expansion and contraction effects when using steel formwork in areas with extreme temperature variations, as this may impact the accuracy of the formwork and the final concrete structure. Proper design considerations and installation techniques can help mitigate any potential issues related to temperature variations.

- Q: How are steel formwork systems assembled and disassembled?

- Steel formwork systems are assembled and disassembled using a simple and efficient process. The assembly starts by erecting the steel panels, which are designed to interlock with each other through various connecting devices such as pins, wedges, or clips. These panels come in different sizes and shapes to accommodate various construction requirements. To assemble the steel formwork system, the panels are aligned and connected together according to the desired shape and dimensions of the structure. The panels are typically secured using pins or wedges to ensure stability and prevent any movement during the concrete pouring process. Once the panels are properly connected, the next step involves installing the necessary support structures such as walers, props, and braces. These elements help to reinforce the formwork system and distribute the loads evenly. Walers are horizontal beams that connect the vertical panels, while props are adjustable vertical supports that provide additional stability. Braces are diagonal members that help in resisting lateral forces. During the concrete pouring process, the steel formwork system holds the wet concrete in place and provides the desired shape and finish to the structure. After the concrete has cured and gained sufficient strength, the dismantling process begins. To disassemble the steel formwork system, the props and braces are removed first, followed by the walers. Once the support structures are taken down, the panels can be easily detached from each other by removing the connecting devices. This can be done by either pulling out the pins or wedges or releasing the clips. The disassembly process is usually done systematically, starting from the top and moving downwards to ensure safety and prevent any accidental collapse. It is important to follow proper safety guidelines and use appropriate tools to avoid any damage to the formwork system or injury to the workers. In conclusion, steel formwork systems are assembled by connecting steel panels and installing support structures, while the disassembly process involves removing the support structures and disconnecting the panels. This systematic approach ensures a safe and efficient construction process, allowing for the reuse of the formwork system in future projects.

- Q: What are the different types of formwork release oils used with steel formwork?

- Steel formwork commonly utilizes various types of formwork release oils to prevent concrete adhesion and facilitate easy removal. These oils include petroleum-based, vegetable-based, water-based, silicone-based, and polymer-based release agents. 1. Petroleum-based release oils, derived from petroleum, are frequently employed in construction projects. They effectively prevent concrete adhesion and enable effortless removal by acting as a barrier between the concrete and the steel formwork. 2. Vegetable-based release oils, such as soybean or canola oil, offer a more environmentally friendly alternative to petroleum-based oils. 3. Water-based release agents are a popular choice due to their non-toxic nature and absence of harmful fumes. They are easy to apply and provide excellent release effects on steel formwork. 4. Silicone-based release agents are renowned for their exceptional release properties. They create a thin layer on the steel formwork, preventing adhesion and ensuring effortless removal of the concrete. Additionally, they contribute to a high-quality finish on the concrete surface. 5. Polymer-based release agents are commonly utilized when a superior finish is desired for the concrete surface. These agents form a thin film on the steel formwork, preventing adhesion and facilitating easy stripping. Selecting the appropriate formwork release oil should be based on project-specific requirements, including the type of concrete, environmental considerations, and desired concrete surface finish. Consulting professionals or referring to manufacturer's guidelines is advisable to ensure the correct release oil is chosen.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork has a reputation for effectively managing concrete bleeding and segregation. Bleeding occurs when water in the concrete mixture rises to the surface, leaving a layer of water on top. Segregation, on the other hand, happens when the solid particles in the concrete mixture separate from the water, causing an uneven distribution. To minimize bleeding and segregation, steel formwork provides a sturdy structure that holds the concrete in place during pouring and curing. The strong construction and tight joints of steel formwork prevent any leaks or seepage, resulting in reduced bleeding. Moreover, steel formwork allows for better control over the placement and compaction of the concrete. The smooth and non-absorbent surface of steel formwork facilitates a uniform distribution of the concrete mixture, minimizing the risk of segregation. Additionally, using steel formwork enables proper vibration and consolidation of the concrete, eliminating any voids or air pockets that could contribute to segregation. Furthermore, steel formwork ensures stability during the curing process, preventing significant movement of the concrete. This stability helps avoid disturbances that could lead to bleeding or segregation. In conclusion, steel formwork is highly effective in managing concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more consistent and consolidated placement of concrete, resulting in a higher quality finished product.

- Q: How does steel formwork contribute to the overall safety of workers?

- There are several ways in which steel formwork contributes to the overall safety of workers. Firstly, its strength and durability provide a stable and secure structure for workers to perform their tasks, minimizing the risk of accidents and collapses. In addition, steel formwork is fire-resistant, offering protection in case of fire emergencies. This feature significantly reduces the risk of injuries and gives workers valuable time to safely evacuate the area. Furthermore, steel formwork is designed to withstand various weather conditions, such as strong winds and heavy rains. This resistance prevents instability or collapse during adverse weather, minimizing the risk of accidents and injuries for workers on-site. Moreover, steel formwork includes safety features like non-slip surfaces and handrails, which enhance worker safety by providing better grip and stability when moving around the structure. These features help prevent common accidents like slips, trips, and falls on construction sites. Another important aspect is that steel formwork is reusable and easy to assemble and disassemble. This reduces the need for workers to carry heavy materials or tools, decreasing the risk of strain injuries and fatigue-related accidents. Lastly, steel formwork is designed to ensure proper support and alignment during concrete pouring, minimizing the risk of structural failures or collapses. This precise alignment guarantees the stability of the structure and reduces the likelihood of accidents that could endanger workers' safety. In conclusion, steel formwork is crucial for enhancing the overall safety of workers. Its strength, durability, fire resistance, weather resistance, non-slip surfaces, and proper support significantly contribute to creating a secure working environment and reducing the risk of accidents, injuries, and structural failures.

- Q: How does steel formwork handle different concrete finishing techniques?

- Steel formwork offers a wide range of possibilities for concrete finishing techniques due to its high versatility. It possesses great strength and durability, enabling it to withstand the pressure and forces exerted throughout various finishing procedures. When aiming for a smooth finish, steel formwork provides a solid and stable surface that facilitates easy pouring and leveling of the concrete. Its rigidity guarantees that the concrete remains in position and does not sag or deform during the finishing process. Consequently, the concrete can be smoothly troweled, resulting in a polished and uniform surface. Steel formwork is also suitable for textured finishes. It can be customized with different patterns and textures to create unique and decorative concrete surfaces. By utilizing specially designed steel formwork, such as those with corrugated or embossed patterns, the concrete can be poured to replicate these designs, resulting in visually appealing textured finishes. Furthermore, steel formwork is capable of accommodating exposed aggregate finishes. This technique involves removing the top layer of concrete to reveal the underlying aggregate stones, thus creating a decorative effect. Steel formwork can be designed with removable panels or inserts that allow the concrete to be poured in a way that exposes the desired amount of aggregate. After the concrete has cured, these removable panels can be easily taken off, revealing the desired exposed aggregate finish. Moreover, steel formwork is suitable for stamped concrete finishes. Stamped concrete involves imprinting patterns or textures onto the concrete surface using specialized stamps. Steel formwork provides a solid foundation for these stamps to be pressed onto, ensuring accurate and consistent imprints. The rigidity of steel formwork prevents the concrete from shifting or deforming during the stamping process, resulting in precise and high-quality stamped finishes. Overall, steel formwork is highly compatible with various concrete finishing techniques. Its strength, stability, and versatility make it an ideal choice for handling different finishing processes, allowing for the creation of smooth, textured, exposed aggregate, and stamped concrete finishes with precision and ease.

- Q: Can steel formwork be used for road construction?

- Yes, steel formwork can be used for road construction. Steel formwork is a popular choice for road construction projects due to its durability, strength, and versatility. It is capable of withstanding heavy loads and pressure, making it suitable for creating sturdy and long-lasting road surfaces. Steel formwork can be easily assembled and disassembled, allowing for efficient construction processes and faster project completion. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for road construction.

- Q: Can steel formwork be used in extreme weather conditions?

- Yes, steel formwork can be used in extreme weather conditions. Steel is a durable and strong material that can withstand harsh weather conditions such as extreme heat, cold, rain, and wind. Unlike other materials like wood or plywood, steel formwork is not affected by moisture or temperature variations, making it suitable for use in extreme weather conditions. Additionally, steel formwork provides better stability and structural strength, ensuring the safety and integrity of the construction project even in adverse weather conditions. However, it is important to consider the proper protection and maintenance of steel formwork to prevent corrosion or damage that can occur over time due to exposure to extreme weather conditions.

- Q: How does steel formwork affect the overall weight of the structure?

- The overall weight of a structure can be significantly influenced by steel formwork. In comparison to traditional timber formwork, steel formwork is generally heavier due to the inherent properties of steel. Steel, being denser and heavier than wood, means that the contribution of steel formwork to the total weight of the structure is greater. Nevertheless, in certain situations, the weight of the steel formwork can also have advantages. The added weight of steel formwork can provide stability and rigidity to the structure during construction, ensuring proper support and shaping of the concrete. This can result in a more precise and long-lasting final structure. Furthermore, steel formwork is typically more durable and can be reused multiple times, unlike timber formwork which often needs replacement after a few uses. This can lead to reduced environmental impact and cost savings in the long term, despite the initial increase in weight caused by steel formwork. Ultimately, the impact of steel formwork on the overall weight of a structure depends on several factors such as project size, complexity, design requirements, and chosen construction method. However, it is crucial to consider the trade-offs between formwork weight and its benefits in terms of stability, durability, and cost-effectiveness.

- Q: How does steel formwork handle different concrete slump values?

- Steel formwork is a versatile and robust solution that effectively manages different concrete slump values. Slump refers to the consistency or fluidity of concrete and is measured by its workability. Due to its inherent strength and durability, steel formwork is designed to accommodate various slump values. First and foremost, steel formwork offers exceptional support and stability to the concrete during pouring and curing. It can withstand the pressure exerted by wet concrete, regardless of its slump value. The rigid structure of steel formwork ensures that it maintains its shape and integrity, even when dealing with high slump concrete. Furthermore, steel formwork provides flexibility in adjusting the formwork panels to suit different slump values. The panels can be easily adjusted or repositioned to create the desired shape or size for the concrete structure. This adaptability allows steel formwork to efficiently accommodate varying slump values without compromising the quality or integrity of the final concrete product. Additionally, steel formwork provides a smooth and even surface finish for the concrete, irrespective of its slump value. The steel panels are precisely manufactured to ensure a consistent and uniform surface finish, enhancing the overall aesthetics of the concrete structure. This is particularly important when dealing with different slump values as it ensures a visually appealing and professional end result. In conclusion, steel formwork is well-equipped to handle different concrete slump values due to its strength, durability, and flexibility. It provides excellent support, stability, and adaptability during the pouring and curing process, resulting in a high-quality finished product. Whether the concrete has a low or high slump value, steel formwork consistently delivers a smooth and visually appealing surface finish, making it a reliable choice for various construction projects.

Send your message to us

Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords