Steel Frame SF140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

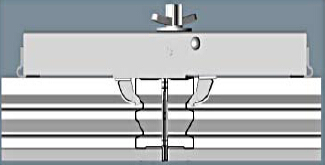

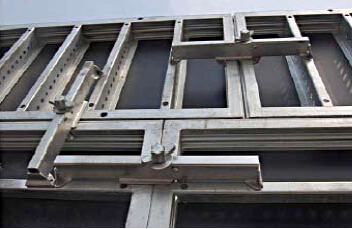

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork affect the overall sound insulation of a building?

- The overall sound insulation of a building is not directly affected by steel formwork. The quality and design of the walls, floors, and ceilings are the main factors that determine sound insulation, regardless of the formwork material used. However, sound insulation may be indirectly influenced by steel formwork during the construction phase. Steel formwork is renowned for its rigidity and strength, which ensures precise and accurate pouring of concrete. This precise construction technique helps minimize gaps and imperfections that can occur during the concrete casting process. Consequently, steel formwork contributes to creating a smoother and more uniform concrete surface, reducing the possibility of sound leakage through cracks or joints. Additionally, steel formwork can be employed to create even and smooth surfaces, facilitating the installation of soundproofing materials like acoustic panels or insulation. These supplementary soundproofing measures, when incorporated during construction, can enhance the overall sound insulation of the building. It is important to recognize that although steel formwork can indirectly impact sound insulation during construction, the primary elements affecting sound insulation are the materials and techniques utilized in constructing walls, floors, and ceilings. Architectural design, insulation materials, and sealing techniques all play a crucial role in achieving optimal sound insulation levels.

- Q: What are the considerations when designing steel formwork for architectural sculptures?

- When designing steel formwork for architectural sculptures, several considerations need to be taken into account. Firstly, the formwork should be able to withstand the weight and pressure of the concrete being poured into it, ensuring structural stability. Additionally, the formwork should be designed in a way that allows for easy installation and removal, as well as ensuring proper alignment and support for intricate or unconventional shapes. The material and thickness of the steel should be chosen carefully to withstand any weather conditions or potential corrosion. Moreover, considerations should be made for any required surface finishes, such as textures or patterns, which may require additional design elements or treatments. Lastly, the cost-effectiveness of the formwork design should also be considered, balancing the required strength and durability with the available budget.

- Q: How does steel formwork handle moisture and humidity?

- Steel formwork is highly resistant to moisture and humidity due to its inherent properties and effective protective measures. The steel used in formwork construction is typically treated with anti-corrosion coatings, such as galvanization or epoxy paint, which create a barrier against moisture penetration. These coatings protect the steel from the corrosive effects of water, preventing rust formation and structural degradation. Additionally, steel formwork systems are designed with tight joints and connections to ensure minimal water ingress. This reduces the risk of moisture accumulation within the formwork, which could potentially weaken the structure or affect the quality of the concrete. Furthermore, steel formwork is non-absorbent, meaning it does not absorb water or humidity. This characteristic prevents swelling, warping, or distortion of the formwork due to moisture exposure. It also ensures consistent and accurate dimensions of the formwork, resulting in precise concrete shapes and finishes. In cases where steel formwork is exposed to high levels of moisture or humidity, such as in marine or coastal environments, additional protective measures can be taken. These may include applying specialized coatings or using stainless steel formwork, which offers superior resistance to corrosion and moisture. Overall, steel formwork is well-suited for handling moisture and humidity. Its resistance to corrosion, non-absorbent nature, and ability to maintain structural integrity even in challenging environmental conditions make it a reliable and durable choice for construction projects.

- Q: How does steel formwork contribute to the efficiency of construction processes?

- Steel formwork contributes to the efficiency of construction processes by providing a durable and reusable framework for casting concrete structures. Its strength and rigidity allow for faster construction progress, as it can withstand the pressure exerted by wet concrete, resulting in shorter construction cycles. Additionally, steel formwork allows for precise and accurate shaping of concrete elements, ensuring the desired dimensions and quality of the final product. Its reusability minimizes waste, reduces costs, and promotes sustainability in construction projects.

- Q: How does steel formwork compare to other types of formwork in terms of durability?

- Steel formwork is known for its exceptional durability compared to other types of formwork. Unlike wooden or plastic formwork, steel formwork is built to withstand heavy loads and repetitive use, making it ideal for projects that require long-term usability. Steel formwork is not affected by weather conditions, moisture, or decay, making it highly resistant to damage and deterioration. It can withstand extreme temperatures, strong winds, and heavy rains without compromising its structural integrity. This durability ensures that steel formwork can be used in various construction projects, including high-rise buildings, bridges, and tunnels, where strength and reliability are crucial. Another advantage of steel formwork is its ability to bear high concrete pressures. The robustness of steel allows it to handle the pressure exerted by wet concrete during the pouring and curing process. This makes steel formwork highly suitable for projects that involve pouring large volumes of concrete, ensuring that the formwork remains intact and can be reused multiple times. Furthermore, steel formwork has a longer lifespan compared to other materials. Due to its durability, it can be used for multiple construction cycles, reducing the need for frequent replacements. This not only saves time and money but also minimizes waste generated during construction. In summary, steel formwork surpasses other types of formwork in terms of durability. Its resistance to weather conditions, high concrete pressures, and long lifespan make it a reliable choice for construction projects that require a strong and long-lasting formwork system.

- Q: How does steel formwork affect the overall labor productivity in construction?

- Steel formwork can have a significant impact on labor productivity in construction. Firstly, steel formwork is known for its durability and strength, which allows it to withstand the pressures and forces exerted during the concrete pouring process. This reduces the need for frequent repairs or replacements, minimizing downtime and increasing overall labor productivity. Additionally, steel formwork offers a high level of accuracy and precision in creating concrete structures. This results in better quality finishes and reduces the need for rework or corrections, saving time and effort for construction workers. The ability to achieve consistent dimensions and smooth surfaces with steel formwork also enhances the overall efficiency of the construction process. Furthermore, steel formwork is known for its ease of assembly and dismantling. The modular nature of steel formwork systems allows for quick and efficient setup, reducing the time spent on formwork erection. Similarly, the ease of dismantling enables faster turnaround times between construction phases, allowing workers to progress to the next task more swiftly. Moreover, steel formwork systems often incorporate features such as adjustable props, clamps, and connectors, making them highly adaptable to various construction requirements. This versatility enables workers to quickly adjust and modify the formwork to accommodate changes in design or construction plans, eliminating delays and improving labor productivity. Lastly, steel formwork can contribute to a safer working environment. The robustness and stability of steel formwork systems offer enhanced protection for construction workers, reducing the risk of accidents and injuries. By ensuring worker safety, steel formwork promotes a more efficient and productive construction process. In summary, steel formwork positively impacts labor productivity in construction by providing durability, accuracy, ease of assembly and dismantling, adaptability, and improved safety. These factors contribute to a more efficient construction process, reducing downtime, rework, and the overall time required for project completion.

- Q: How does steel formwork affect the overall cost-effectiveness of a construction project?

- There are several ways in which a construction project can benefit from the use of steel formwork, making it a cost-effective choice. Firstly, steel formwork is incredibly durable and can be reused multiple times without experiencing significant wear and tear. This means that there is no need for frequent replacements, resulting in cost savings in terms of materials. Furthermore, steel formwork provides excellent dimensional stability, ensuring precise and accurate construction. This eliminates the need for excessive adjustments and rework, saving both time and money. Additionally, the smooth surface finish provided by steel formwork reduces the need for additional plastering or finishing, further reducing construction costs. Moreover, steel formwork is known for its strength and load-bearing capacity. This allows for larger spans and fewer support beams, reducing the amount of materials required and consequently lowering costs. The structural integrity and stability of steel formwork also contribute to a reduction in the number of labor hours required for installation and dismantling, resulting in labor cost savings. In terms of time efficiency, steel formwork offers quicker assembly and disassembly compared to traditional formwork systems. This can significantly reduce construction durations, leading to cost savings associated with labor, equipment rental, and overhead expenses. Additionally, steel formwork is highly adaptable and versatile, making it suitable for a wide range of construction projects. Its flexibility allows for customization and adjustments to meet project requirements, reducing the need for multiple formwork systems for different construction elements. Overall, the use of steel formwork in a construction project can lead to significant cost savings. Its durability, reusability, dimensional accuracy, reduced finishing requirements, material efficiency, time efficiency, and adaptability all contribute to improved cost-effectiveness. It not only minimizes material and labor costs but also enhances productivity.

- Q: What is the lifespan of steel formwork compared to other types of formwork?

- The lifespan of steel formwork is generally longer compared to other types of formwork. Steel is a highly durable material that can withstand heavy loads and extreme weather conditions, making it ideal for construction purposes. With proper maintenance and care, steel formwork can last for several decades. In comparison, other types of formwork such as wooden or plastic formwork have a shorter lifespan. Wood is susceptible to rotting, warping, and termite infestation, which can significantly reduce its lifespan. Plastic formwork, while lightweight and easy to handle, may deteriorate over time due to exposure to UV radiation and general wear and tear. Steel formwork also offers the advantage of being reusable. Once a concrete structure is completed, the steel formwork can be dismantled and used for other construction projects, reducing the need for new formwork and minimizing waste. Although steel formwork may require a larger upfront investment compared to other materials, its longer lifespan and reusability make it a cost-effective choice in the long run. Additionally, steel formwork provides excellent structural stability, ensuring the integrity and quality of the concrete structure being formed.

- Q: What are the considerations when designing steel formwork for bridges?

- When designing steel formwork for bridges, there are several considerations to take into account. Firstly, the load capacity of the formwork must be determined, ensuring that it can support the weight of the wet concrete and any construction equipment. Additionally, the formwork should be designed to withstand the forces generated during the pouring and curing of the concrete, such as lateral pressure and vibration. The formwork system should also be easy to assemble, disassemble, and adjust to accommodate different bridge geometries and dimensions. It is important to consider the durability and corrosion resistance of the steel used in the formwork, as bridges are often exposed to harsh environmental conditions. Finally, the design should incorporate safety measures, such as guardrails and access platforms, to ensure the safety of workers during construction.

- Q: What are the common safety guidelines when working with steel formwork?

- When working with steel formwork, there are several common safety guidelines that should be followed to ensure the well-being of workers and prevent accidents. These guidelines include: 1. Personal Protective Equipment (PPE): All workers should wear appropriate PPE, including safety helmets, safety glasses, gloves, and steel-toed boots. This will protect them from falling objects, cuts, and other potential hazards. 2. Training and Competency: Workers should receive proper training on how to use and handle steel formwork. They should be knowledgeable about the specific tasks they are assigned and have the necessary skills to perform them safely. 3. Inspections: Regular inspections of the steel formwork should be conducted before and during use to ensure that it is in good condition and free from defects. Any damaged or faulty parts should be repaired or replaced immediately. 4. Proper Handling: Steel formwork can be heavy and cumbersome, so it is essential to use proper lifting techniques and mechanical aids when moving or positioning it. Avoiding excessive strain and overexertion can help prevent musculoskeletal injuries. 5. Secure Installation: The formwork should be securely installed and braced to prevent collapse or displacement during concrete pouring. It should be properly aligned and supported to ensure stability throughout the construction process. 6. Fall Protection: Adequate fall protection measures, such as guardrails or safety harnesses, should be in place when working at heights. Additionally, workers should be cautious of slippery surfaces and take necessary precautions to prevent slips, trips, and falls. 7. Hazard Communication: Clear signage and warnings should be posted to alert workers to potential hazards and provide instructions on safety procedures. Communication among workers and proper coordination is also crucial to prevent accidents. 8. Regular Maintenance: Routine maintenance and cleaning of the steel formwork should be performed to remove debris, rust, or other materials that could compromise its integrity. This will help ensure its safety and longevity. By following these common safety guidelines when working with steel formwork, the risk of accidents and injuries can be significantly reduced, creating a safer work environment for all involved.

Send your message to us

Steel Frame SF140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords