Steel-frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

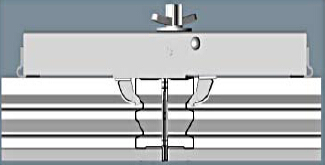

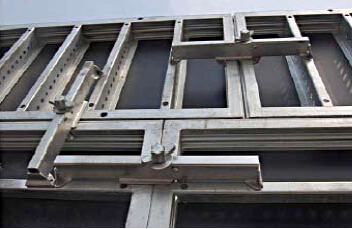

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for both interior and exterior structures?

- Yes, steel formwork can be used for both interior and exterior structures. Steel is a versatile and durable material that can withstand various weather conditions and is suitable for use in both indoor and outdoor environments. It provides excellent strength and stability, making it an ideal choice for constructing structures such as walls, columns, slabs, and beams. Additionally, steel formwork is reusable, which makes it cost-effective and environmentally friendly. Whether it is for interior or exterior construction, steel formwork offers a reliable and efficient solution.

- Q: What are the different types of ties used in steel formwork construction?

- There are several types of ties commonly used in steel formwork construction. These ties serve the purpose of holding the formwork panels together and ensuring the stability and integrity of the structure. Some of the different types of ties used in steel formwork construction include: 1. Snap ties: These are the most commonly used ties in steel formwork construction. They consist of two parts - a metal rod and a flat plate. The rod is inserted through holes in the formwork panels, and the plate is then attached to hold the panels together. Snap ties are quick and easy to install and can be easily removed after the concrete has cured. 2. Tie rods: These are long steel rods that are threaded on both ends. They are used to hold the formwork panels together by passing them through holes in the panels and securing them with nuts and washers. Tie rods provide strong and stable connections between the panels and can withstand high pressure and loads. 3. She-bolts: These are similar to tie rods but have a fixed female thread at one end. She-bolts are used in combination with wing nuts and washers to hold the formwork panels together. They are particularly useful in applications where the tie rods need to be quickly and easily removed. 4. Flat ties: These are steel wires or bars that are flat in shape. They are inserted through holes in the formwork panels and secured with cones or washers. Flat ties provide a secure connection between the panels and are commonly used in large-scale construction projects. 5. Coil ties: These are flexible steel wires that are coiled at one end and have a threaded end at the other. Coil ties are inserted through holes in the formwork panels and secured with cones or washers. They are particularly useful in curved or irregular-shaped structures. 6. Combination ties: These ties combine the features of snap ties and tie rods. They consist of a metal rod with a flat plate at one end and a threaded end at the other. Combination ties are versatile and can be used in various formwork applications. It is important to choose the appropriate type of tie based on the specific requirements of the steel formwork construction project. The choice of tie will depend on factors such as the size and shape of the structure, the load-bearing capacity needed, and the ease of installation and removal.

- Q: Can steel formwork be used in educational or institutional construction projects?

- Educational or institutional construction projects can indeed make use of steel formwork. Steel formwork proves to be a versatile and durable solution that brings numerous advantages to such projects. To begin with, the high strength and stability offered by steel formwork are crucial when it comes to constructing large and intricate structures commonly found in educational or institutional buildings. Its ability to withstand heavy loads ensures a secure framework for concrete placement, making it especially valuable in projects featuring multiple levels or large spans. Furthermore, the reusability of steel formwork can lead to significant reductions in construction costs and waste. Once the concrete has set, the steel formwork can be dismantled and utilized in another section of the building or even in future projects. This not only saves money but also supports sustainability efforts by minimizing the requirement for new materials. In addition, steel formwork allows for precise and accurate construction. It can be easily adjusted and modified to accommodate various architectural and design specifications. This proves to be of utmost importance in educational or institutional buildings where specific layouts and dimensions are necessary to meet the functional needs of classrooms, laboratories, offices, or other facilities. Moreover, steel formwork facilitates faster construction in comparison to traditional timber formwork. Its lightweight nature and ease of assembly improve efficiency, reducing construction time and enabling earlier project completion. This proves to be particularly advantageous in educational or institutional projects where tight deadlines may exist due to academic schedules or other time constraints. Lastly, steel formwork enhances safety measures during construction. Its robust structure guarantees stability, minimizing the risk of accidents or structural failures. Additionally, steel formwork provides a safer working environment for construction workers as it eliminates the need for excessive scaffolding or temporary supports. In conclusion, steel formwork presents itself as a suitable choice for educational or institutional construction projects, offering strength, durability, reusability, precision, efficiency, and safety. These qualities make it an incredibly beneficial solution for the construction of complex and functional buildings.

- Q: Can steel formwork be used for foundation construction?

- Yes, steel formwork can be used for foundation construction. Steel formwork provides strength, durability, and stability, making it suitable for constructing foundations that require support and resistance to external pressures. It allows for accurate and precise shaping of foundations and can be easily assembled, disassembled, and reused, making it a cost-effective choice for foundation construction.

- Q: Can steel formwork be used for different types of concrete finishes?

- Yes, steel formwork can be used for different types of concrete finishes. Steel formwork is versatile and can be easily adjusted and customized to achieve different finishes, such as smooth, textured, or patterned surfaces. It provides a strong and rigid structure, allowing for precise shaping and detailing of the concrete. Additionally, steel formwork can be reused multiple times, making it cost-effective for various types of concrete finishes.

- Q: How does steel formwork contribute to the overall durability of the concrete structure?

- Steel formwork contributes to the overall durability of a concrete structure in several ways. Firstly, steel formwork provides a strong and rigid framework for pouring and shaping the concrete. This ensures that the concrete is properly supported during the curing process, preventing any deformation or collapse that could compromise the structure's integrity. Additionally, steel formwork is highly resistant to the corrosive effects of concrete, which contains alkaline substances that can slowly erode other materials over time. This resistance to corrosion ensures that the formwork remains stable and intact throughout the construction process, maintaining the shape and dimensions of the concrete elements. Moreover, steel formwork allows for precise and accurate construction, resulting in a concrete structure with consistent dimensions and smooth finishes. This precision minimizes the chances of structural weaknesses or flaws in the concrete, enhancing its overall durability. Furthermore, steel formwork is reusable, making it a cost-effective option for construction projects. By using steel formwork multiple times, the overall durability of the concrete structure is improved as the formwork retains its strength and stability over numerous applications. In conclusion, steel formwork plays a crucial role in enhancing the overall durability of a concrete structure. Its strength, resistance to corrosion, precision, and reusability ensure that the concrete is properly supported, accurately constructed, and able to withstand external forces, contributing to a long-lasting and robust structure.

- Q: Can steel formwork be used for tunnel linings?

- Tunnel linings can indeed utilize steel formwork, a flexible and long-lasting alternative that can be tailored to meet the precise demands of tunnel construction. This solution furnishes a robust and inflexible framework, able to withstand the immense pressures and forces exerted by the surrounding terrain and potential water infiltration. Furthermore, steel formwork boasts the added benefit of reusability, rendering it an economically viable choice for tunnel linings. Additionally, assembling and disassembling steel formwork is a simple task, facilitating the expedient and punctual construction of tunnel linings.

- Q: How does steel formwork contribute to faster construction?

- There are several ways in which steel formwork speeds up construction. Firstly, steel formwork is exceptionally durable and can endure multiple uses. This means it can be reused on various construction projects, reducing the need to constantly manufacture new formwork. This not only saves time but also cuts costs associated with buying new materials for each project. Moreover, steel formwork is quick and simple to assemble and disassemble. The modular nature of steel formwork allows for efficient installation and removal, enabling construction teams to complete projects at a faster pace. This is particularly advantageous for projects with tight schedules or where speed is crucial. Furthermore, steel formwork provides a smooth and consistent surface finish, eliminating the need for additional plastering or finishing work. This saves time and effort during the construction process, as there is no need to wait for plaster or other finishing materials to dry before moving on to the next stage. Additionally, steel formwork offers greater design flexibility. Steel can be easily fabricated into various shapes and sizes, allowing for the construction of complex structures. This versatility eliminates the need for expensive and time-consuming custom formwork solutions, as steel formwork can be adapted to meet the specific requirements of each project. Lastly, steel formwork is renowned for its excellent strength and stability. It can withstand heavy loads and adverse weather conditions, ensuring the safety and stability of the construction site. This reduces the risk of delays due to structural issues or the need for additional reinforcements, allowing the construction process to progress smoothly and efficiently. Overall, the use of steel formwork in construction projects speeds up construction by providing durability, easy assembly and disassembly, a smooth surface finish, design flexibility, and enhanced strength and stability. These factors combined help to streamline the construction process and reduce the overall project timeline.

- Q: How does steel formwork affect the overall fire resistance of a structure?

- Steel formwork does not directly affect the overall fire resistance of a structure as it is primarily used for temporary support during concrete pouring and construction. The fire resistance of a structure is generally determined by the materials used in its construction, such as the type of concrete, insulation, and fireproofing systems. However, steel formwork can indirectly contribute to the fire resistance by ensuring the proper placement and compaction of concrete, which is a key factor in achieving the desired fire resistance rating. The strength and durability of the concrete, when properly mixed and compacted, can enhance the overall fire resistance of the structure. Additionally, steel formwork can provide a smooth and uniform surface finish, which can facilitate the application of fireproofing materials. Fireproofing coatings or sprays are often used to enhance the fire resistance of structural elements, such as beams and columns. The smooth surface provided by steel formwork can help ensure an even and effective application of these fireproofing materials, further enhancing the fire resistance of the structure. It is important to note that while steel formwork itself is not fire resistant, it is typically removed once the concrete has cured, and the final fire resistance of the structure is determined by the materials used in its permanent construction.

- Q: Is steel formwork suitable for projects with high concrete temperature requirements?

- Steel formwork is generally not considered suitable for projects with high concrete temperature requirements. This is because steel has a high thermal conductivity, meaning it can rapidly transfer and dissipate heat. When exposed to high concrete temperatures, steel formwork can become extremely hot, potentially leading to deformation, warping, or even failure. In contrast, materials with lower thermal conductivity, such as timber or plastic formwork, are better suited for projects with high concrete temperature requirements. These materials provide better insulation and can handle the increased heat without compromising their structural integrity. However, it's important to note that there are certain types of steel formwork that are specifically designed to withstand higher concrete temperatures. These specialized formwork systems are typically made from heat-resistant alloys or have additional insulation layers to minimize the impact of temperature on the steel. Ultimately, the suitability of steel formwork for projects with high concrete temperature requirements depends on the specific type of steel formwork being used and its ability to withstand and dissipate heat effectively. It is recommended to consult with structural engineers and formwork suppliers to determine the most appropriate formwork material for such projects.

Send your message to us

Steel-frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords