Steel frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

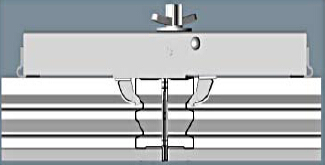

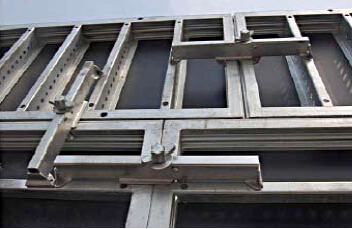

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle different concrete early age strength development?

- Steel formwork is a versatile and durable option for handling different concrete early age strength development. Due to its strength and rigidity, steel formwork provides excellent support during the initial stages of concrete curing. It can withstand the high pressures exerted by fresh concrete, ensuring that the formwork remains intact and stable during the early age strength development. Additionally, steel formwork allows for efficient and precise placement of concrete, enabling proper consolidation and uniform curing. Overall, steel formwork is a reliable choice that can effectively handle the varying early age strength development of concrete.

- Q: What are the common design considerations for steel formwork in hot climates?

- Some common design considerations for steel formwork in hot climates include selecting materials with high heat resistance, incorporating proper ventilation and shading to minimize heat buildup, ensuring adequate structural support to withstand thermal expansion, and implementing effective methods for concrete curing to prevent cracking due to rapid drying. Additionally, attention should be given to the durability and maintenance of the formwork system to withstand the harsh conditions and frequent use in hot climates.

- Q: What are the different types of steel formwork available?

- In the construction industry, there exists a variety of steel formwork options, each possessing its own distinctive characteristics and benefits. Some of the most prevalent variations include: 1. Modular steel formwork: This formwork type comprises pre-made steel panels that can be effortlessly assembled and disassembled. It boasts customization capabilities and can accommodate concrete structures of diverse shapes and sizes. 2. Tunnel formwork: Specifically designed for tunnel and underground structure construction, this formwork variant is forged from steel plates. Its robust construction enables it to withstand high pressure and deliver a polished finish to the concrete. 3. Climbing formwork: Tailored for tall structures such as skyscrapers, climbing formwork is engineered to be lifted and moved vertically as construction progresses. This type of formwork ensures both safety and efficiency during the construction of multi-story buildings. 4. Steel soldier formwork: A versatile and cost-effective option often employed for walls and columns, steel soldier formwork is constructed using steel beams and soldiers. It can be easily adjusted to accommodate different heights and widths. 5. Steel frame formwork: Comprised of steel frames with attached plywood or metal panels, this lightweight formwork type is easy to handle and guarantees a smooth concrete finish. 6. Steel table formwork: Ideal for large horizontal slabs, steel table formwork utilizes steel tables supported by props or scaffolding. Its quick assembly and dismantling make it perfect for projects with tight timelines. These examples represent only a fraction of the available steel formwork options. The selection of formwork depends on project-specific requirements, including the structure type, load-bearing capacity, and desired finish.

- Q: Steel formwork in the construction project, after the completion of concrete pouring, the wall surface from the powder seriously how to deal with?

- There is a problem with the ratio of the concrete itself.

- Q: Can steel formwork be used for high-rise construction projects?

- Yes, steel formwork can be used for high-rise construction projects. Steel formwork is known for its strength and durability, making it suitable for heavy-duty applications such as high-rise construction. It provides excellent stability and support to the concrete during the pouring and curing process, ensuring the structural integrity of the building. Additionally, steel formwork can be easily assembled and disassembled, making it efficient for use in tall structures where multiple floors need to be constructed. Its reusable nature also allows for cost savings in the long run. Overall, steel formwork is a reliable and popular choice for high-rise construction projects.

- Q: Can steel formwork be used for both vertical and horizontal concrete elements?

- Yes, steel formwork can be used for both vertical and horizontal concrete elements. Steel formwork is highly versatile and can be easily assembled and disassembled, making it suitable for various types of concrete structures. It provides a strong and durable support system for pouring concrete, ensuring the desired shape and finish of the concrete element. Whether it is for walls, columns, beams, slabs, or any other concrete component, steel formwork can be tailored and adjusted to meet the specific requirements of the project. Its ability to withstand high pressure and heavy loads makes it ideal for both vertical and horizontal applications. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for construction projects.

- Q: What are the different types of formwork anchors used in steel formwork?

- There are several types of formwork anchors that are commonly used in steel formwork. These anchors are essential for securing the formwork to the structure and ensuring the stability and safety of the construction process. Some of the different types of formwork anchors used in steel formwork include: 1. Wedge Anchor: This type of anchor consists of a threaded rod with a wedge-shaped end. It is inserted into a pre-drilled hole in the concrete structure and secured by tightening a nut on the threaded end. The wedge anchor provides a strong grip and is commonly used for securing formwork to concrete walls or slabs. 2. Screw Anchor: Screw anchors, also known as self-tapping anchors, are designed for use in softer materials such as wood or light-gauge steel. They have a threaded body that is screwed into the material, providing a secure connection for the formwork. Screw anchors are easy to install and remove, making them a popular choice for temporary formwork applications. 3. Hook Anchor: This type of anchor is shaped like a hook and is typically embedded into the concrete structure during the pouring process. The formwork is then attached to the hook using bolts or other fasteners. Hook anchors provide a strong and reliable connection and are commonly used in applications where high loads or lateral forces are expected. 4. Swift Lift Anchor: Swift lift anchors are specifically designed for lifting and handling precast concrete elements, including steel formwork. These anchors are embedded into the structure during the pouring process and provide a safe and efficient method for lifting and positioning the formwork. 5. Plate Anchor: Plate anchors consist of a flat plate with holes for bolts or other fasteners. They are commonly used in steel formwork systems to secure the formwork to the structure. Plate anchors are versatile and can be easily adjusted or relocated as needed. 6. Chemical Anchor: Chemical anchors are used when a strong and permanent connection is required. These anchors consist of a resin or adhesive that is injected into a pre-drilled hole in the concrete structure. The steel formwork is then attached to the chemical anchor, creating a secure bond. Each type of formwork anchor has its own unique advantages and is suitable for different applications. The choice of anchor will depend on factors such as the type of structure, the load requirements, and the duration of use. It is important to select the appropriate anchor and ensure proper installation to ensure the safety and stability of the formwork system.

- Q: Can steel formwork be used for structures with high fire resistance requirements?

- Yes, steel formwork can be used for structures with high fire resistance requirements. Steel is known for its excellent fire resistance properties, as it does not burn or contribute to the spread of fire. Steel formwork can withstand high temperatures and maintain its structural integrity, making it suitable for use in fire-resistant structures.

- Q: How does steel formwork affect the overall construction productivity?

- Steel formwork is a construction technique that utilizes metal panels and supports to create temporary molds or frames for pouring concrete. This method offers several advantages over traditional timber formwork, including enhanced durability, reusability, and flexibility in design. Consequently, steel formwork significantly affects the overall construction productivity in multiple ways. Firstly, steel formwork contributes to increased construction efficiency by reducing the time required for formwork assembly and dismantling. Unlike timber formwork, steel panels are prefabricated and easily interconnected, allowing for swift installation and disassembly. This results in reduced labor hours and faster completion of formwork activities, ultimately accelerating the construction process. Moreover, the durability of steel formwork positively impacts productivity. Steel panels can withstand harsh weather conditions, extreme temperatures, and heavy loads, ensuring their longevity and reusability. As a result, contractors can reuse steel formwork on multiple projects, eliminating the need for frequent replacement and reducing material costs. The ability to reuse formwork not only saves time and money but also minimizes waste generation and promotes sustainability in the construction industry. Additionally, steel formwork offers greater flexibility in design, enabling the construction of complex structures with precision. The modularity and adjustability of steel panels allow for easy customization according to project requirements, resulting in accurate and consistent concrete placements. This precision eliminates the need for excessive concrete rework, reducing material waste and saving construction time. The speed and accuracy provided by steel formwork positively impact overall construction productivity. Furthermore, steel formwork enhances safety on construction sites. Its sturdy structure and secure connections ensure stability during concrete pouring, minimizing the risk of accidents or structural failures. This increased safety reduces downtime caused by injuries or damages, ultimately improving productivity by maintaining a continuous workflow. In conclusion, steel formwork significantly affects overall construction productivity through various means. Its quick assembly and dismantling, durability, reusability, flexibility in design, and improved safety contribute to faster construction processes, reduced material waste, and enhanced efficiency. Embracing steel formwork techniques can lead to significant time and cost savings, ultimately benefiting the construction industry as a whole.

- Q: What are the different types of coatings used on steel formwork?

- Steel formwork can be protected and its performance enhanced through the use of various types of coatings. These coatings are typically applied to the steel surface to prevent corrosion, increase durability, and improve the overall appearance of the formwork. One commonly used coating for steel formwork is epoxy. Epoxy coatings are recognized for their excellent resistance to chemicals, abrasion, and impact. They create a hard, smooth, and long-lasting surface that can withstand harsh environments and heavy usage. Additionally, epoxy coatings adhere well to the steel surface, ensuring long-term protection against corrosion. Another frequently employed coating for steel formwork is galvanizing. Galvanizing involves applying a zinc layer to the steel surface through hot-dip galvanization. This coating provides exceptional corrosion resistance and helps prolong the formwork's lifespan. Galvanized coatings are particularly suitable for formwork utilized in outdoor or marine environments where exposure to moisture and severe weather conditions is expected. Polyurethane coatings are also utilized on steel formwork to offer high levels of protection and durability. These coatings exhibit outstanding resistance to chemicals, abrasion, and UV radiation, making them ideal for formwork used in construction projects where exposure to harsh elements is common. Furthermore, polyurethane coatings provide a smooth and glossy finish, enhancing the formwork's appearance. Apart from these coatings, there are numerous other types available, such as acrylic coatings, polyester coatings, and powder coatings. Acrylic coatings are known for their strong adhesion and resistance to weather conditions, while polyester coatings offer excellent durability and chemical resistance. On the other hand, powder coatings are applied electrostatically and deliver a highly protective and decorative finish. Ultimately, the choice of coating for steel formwork depends on the specific requirements of the project, including anticipated environmental conditions, desired durability, and aesthetic preferences. It is crucial to carefully consider the properties and advantages of each coating type to ensure that the formwork is adequately protected and performs optimally throughout its lifespan.

Send your message to us

Steel frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords