Steel-Frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

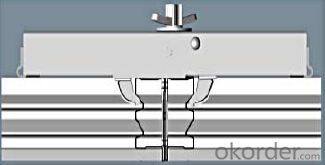

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork prevent concrete segregation during pouring?

- Steel formwork prevents concrete segregation during pouring by providing a rigid and stable structure to hold the concrete in place. The steel panels are designed to be strong and durable, ensuring that they do not deform or flex under the weight and pressure of the concrete. This prevents the concrete from separating and segregating, which can occur if the formwork is not sturdy enough. Additionally, steel formwork is designed with tight joints and connections, minimizing the risk of leakage. This is important because if water from the concrete mixture leaks out, it can lead to the separation and settling of the aggregates, resulting in segregation. The tight joints also help in maintaining the desired shape and dimensions of the concrete structure. Furthermore, steel formwork is often coated or treated to prevent any chemical reaction between the concrete and the steel. This is important as such reactions can cause the concrete to segregate and weaken over time. By providing a strong and stable framework, preventing leakage, and avoiding chemical reactions, steel formwork ensures that the concrete mixture remains homogeneous and properly integrated, thus preventing segregation during pouring.

- Q: Can steel formwork be used for precast concrete tanks?

- Yes, steel formwork can be used for precast concrete tanks. Steel is a popular choice for formwork due to its strength, durability, and versatility. It provides the necessary support and shape for the concrete to be poured and cured, ensuring that the tank has the desired dimensions and structural integrity. Steel formwork can be designed and fabricated to meet the specific requirements of precast concrete tanks, allowing for precise and efficient construction. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for precast concrete tank production.

- Q: Can steel formwork be used for projects with limited formwork transportation options?

- Yes, steel formwork can be used for projects with limited formwork transportation options. Steel formwork is known for its durability, strength, and reusability, making it an ideal choice for projects that require transportation over long distances or difficult terrains. Unlike traditional wood formwork, steel formwork can withstand the rigors of transportation without getting damaged or deformed. Furthermore, steel formwork is lightweight compared to other materials used for formwork, such as concrete or timber, which makes it easier to transport even in areas with limited transportation options. The lightweight nature of steel formwork not only reduces transportation costs but also allows for easier handling and installation on-site. Additionally, steel formwork can be easily disassembled and reassembled, making it suitable for projects that require frequent formwork transportation. The modular design of steel formwork allows for easy transportation and reconfiguration, ensuring that the formwork can be efficiently transported to different project sites as needed. In conclusion, steel formwork is a versatile and practical solution for projects with limited formwork transportation options. Its durability, lightweight nature, and ease of disassembly and reassembly make it a suitable choice for projects that require formwork to be transported over long distances or difficult terrains.

- Q: Can steel formwork be used for both residential and infrastructure projects?

- Indeed, steel formwork is applicable to both residential and infrastructure projects. It boasts numerous benefits, such as its strength, durability, and reusability, which render it suitable for a wide array of construction endeavors. Within residential projects, steel formwork can be employed to construct foundations, walls, slabs, and columns, presenting a robust and efficient solution. Similarly, infrastructure projects can utilize steel formwork to erect bridges, tunnels, highways, and other expansive structures. Its adaptability permits customization to meet specific project requirements while withstanding heavy loads and adverse weather conditions. Moreover, the ease with which steel formwork can be assembled, disassembled, and reused renders it a cost-effective choice for both types of projects. Ultimately, steel formwork proves to be a highly versatile and practical option for diverse construction purposes, making it an ideal fit for both residential and infrastructure projects.

- Q: What are the different types of connections used in steel formwork construction?

- There are several types of connections used in steel formwork construction, each serving a specific purpose. 1. Bolted connections: These are the most common type of connection used in steel formwork construction. Bolted connections involve using bolts, nuts, and washers to secure two or more steel formwork components together. This type of connection provides a strong and rigid joint, and it is relatively easy to assemble and disassemble. 2. Welded connections: Welded connections involve fusing two or more steel formwork components together using heat and pressure. This type of connection is often used for permanent structures or where a high level of strength and rigidity is required. Welded connections are typically more time-consuming and require skilled labor. 3. Clamped connections: Clamped connections involve using clamps or brackets to hold steel formwork components together. This type of connection is often used for temporary structures or where frequent disassembly and reassembly is required. Clamped connections are quick to assemble and disassemble and do not require specialized skills or equipment. 4. Interlocking connections: Interlocking connections involve using specially designed interlocking mechanisms to connect steel formwork components. These connections often include tabs, slots, or grooves that fit together, providing a secure and stable joint. Interlocking connections are commonly used in modular formwork systems, where quick and easy assembly is required. 5. Adhesive connections: Adhesive connections involve using epoxy or other adhesive materials to bond steel formwork components together. This type of connection provides a seamless and smooth joint, and it is often used for architectural or decorative purposes. Adhesive connections require proper surface preparation and curing time to achieve maximum strength. Overall, the choice of connection type in steel formwork construction depends on factors such as the desired strength and rigidity, the type of structure being built, the level of reusability, and the available resources and expertise. It is important to select the appropriate connection type to ensure the safety and stability of the formwork system.

- Q: Can steel formwork be used in high-temperature environments?

- High-temperature environments are not suitable for the use of steel formwork. This is due to the high coefficient of thermal expansion possessed by steel, causing significant expansion upon exposure to high temperatures. Such expansion can result in warping, distortion, and even structural failure of the formwork. Moreover, steel can lose its strength and load-bearing capacity when subjected to elevated temperatures, rendering it unsafe for use in high-temperature surroundings. Therefore, it is advisable to opt for alternative formwork materials like heat-resistant plastics or composite materials that are explicitly engineered for high-temperature applications.

- Q: What are the considerations when designing steel formwork for underground parking structures?

- When designing steel formwork for underground parking structures, several key considerations should be taken into account. Firstly, the formwork must be able to withstand the heavy loads and pressures exerted by the surrounding soil and any potential water infiltration. It is crucial to ensure the strength, stability, and durability of the formwork system to prevent any structural failures or collapses. Additionally, careful attention should be paid to the formwork's waterproofing capabilities. Adequate waterproofing measures, such as the use of sealants or membranes, must be incorporated to protect the structure against potential water ingress, which could lead to corrosion and long-term damage. Moreover, the design should allow for efficient and safe construction. This includes considering factors such as ease of assembly and disassembly, ensuring proper access and working space for construction workers, and incorporating appropriate safety measures to prevent accidents during the formwork installation and removal processes. Lastly, the formwork design should also take into consideration the desired architectural and aesthetic elements of the parking structure. This may involve incorporating specific finishes, textures, or patterns on the exposed concrete surfaces, which can enhance the overall visual appeal of the underground parking facility. Overall, the considerations when designing steel formwork for underground parking structures revolve around ensuring structural integrity, waterproofing capabilities, construction efficiency, safety, and meeting the desired architectural requirements.

- Q: How does steel formwork contribute to the overall strength of a structure?

- Using steel panels and frames, steel formwork is a construction technique employed to create temporary molds for pouring concrete. This method offers several advantages over traditional wooden formwork, particularly in terms of strengthening a structure. Firstly, steel formwork boasts exceptional durability and resistance to wear and tear. Steel is a sturdy material capable of withstanding heavy loads and extreme weather conditions. Unlike wooden formwork, it does not warp, crack, or deteriorate over time, ensuring the structure's strength and integrity are maintained for an extended period. Furthermore, steel formwork provides superior dimensional stability compared to other materials. The precision fabrication of steel panels and frames guarantees accurate measurements and consistent shapes. This precision allows for a more even distribution of concrete, resulting in a stronger structure with reduced cracks or weaknesses. Moreover, steel formwork allows for greater flexibility in design and construction. The strength of steel permits the creation of intricate and complex structures that may not be achievable with alternative formwork materials. The versatility of steel formwork enables engineers to design structures with unique shapes and configurations, ultimately enhancing their overall strength and load-bearing capacity. Additionally, steel formwork contributes to the overall strength of a structure by offering excellent support and reinforcement during the concrete pouring process. Acting as a framework, the steel panels and frames hold the concrete in place until it solidifies and gains strength. This ensures proper and optimal curing of the concrete, resulting in a structurally sound and resilient structure. In conclusion, steel formwork plays a vital role in enhancing the overall strength of a structure. Its durability, dimensional stability, flexibility in design, and support during the concrete pouring process all contribute to creating a robust and long-lasting structure. By choosing steel formwork, construction projects can achieve higher levels of strength, durability, and structural integrity.

- Q: What are the considerations when designing a steel formwork system?

- When designing a steel formwork system, several considerations need to be taken into account. Firstly, the desired shape and dimensions of the concrete structure need to be carefully planned. This includes considering the load-bearing capacity, stability, and rigidity requirements of the formwork system. Secondly, the choice of steel material is crucial. The steel should have high tensile strength, durability, and resistance to corrosion and wear. Additionally, factors such as weight, ease of handling, and reusability should be considered to optimize the formwork system's efficiency and cost-effectiveness. Furthermore, the formwork system should be designed to allow for easy assembly, disassembly, and adjustments on-site. Components such as panels, beams, props, and connectors should be designed for quick and secure installation, ensuring efficient construction processes. Safety is another critical consideration. The formwork system needs to be designed to withstand the forces and pressures exerted by wet concrete, preventing any collapse or failure during the pouring and curing stages. Proper bracing, tie systems, and anchorage points should be incorporated to ensure the stability and safety of the entire structure. Lastly, environmental factors should be taken into consideration. The formwork system should consider factors such as noise and vibration reduction, waste management, and the use of sustainable materials and practices to minimize the impact on the surrounding environment. Overall, a well-designed steel formwork system should address structural requirements, material properties, ease of use, safety, and sustainability to ensure successful and efficient concrete construction projects.

- Q: How does steel formwork affect the overall waterproofing of a building?

- The main purpose of steel formwork is to provide stability and shape to wet concrete during the construction process. It does not directly affect the overall waterproofing of a building. Waterproofing is typically achieved through the use of waterproof membranes, sealants, or coatings applied to the external surfaces of the structure. Proper installation and sealing of the formwork joints are important to prevent water leakage during the concrete pouring process. Any gaps or cracks in the formwork can allow water to seep into the structure, potentially compromising the waterproofing system. Additionally, the choice of formwork material indirectly influences the overall waterproofing of a building. Steel formwork, being durable and robust, can withstand the pressure of wet concrete without deforming or leaking. This ensures that the concrete is shaped and compacted correctly, resulting in a more solid and stable structure. A well-constructed concrete framework indirectly contributes to the building's waterproofing capabilities by enhancing its integrity and longevity. In conclusion, while steel formwork does not directly impact the overall waterproofing of a building, it is crucial for maintaining the structural integrity of the concrete during construction. Proper installation and sealing of formwork joints are necessary to prevent water leakage. Ultimately, the choice and correct application of appropriate waterproofing materials determine the building's overall waterproofing performance.

Send your message to us

Steel-Frame Formwork system SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords