Steel-Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

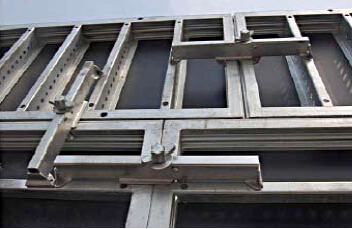

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

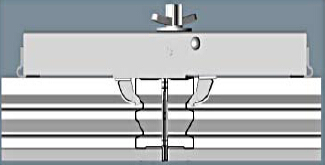

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork affect the overall project coordination and scheduling?

- The overall project coordination and scheduling can be significantly impacted by steel formwork. Firstly, steel formwork is renowned for its durability and strength, enabling it to withstand the pressure and weight of concrete pouring. Consequently, construction can proceed at a faster pace, minimizing delays and ensuring the project remains on schedule. Moreover, steel formwork offers a remarkable level of accuracy and precision in shaping and dimensioning the concrete structures. This precision reduces the need for rework and adjustments, saving time and preventing disruptions to the schedule. Regarding project coordination, steel formwork promotes better communication and collaboration among the different teams involved in the construction process. The standardized and modular nature of steel formwork guarantees that all parties work with the same materials and dimensions, facilitating smoother coordination and reducing conflicts. Additionally, steel formwork is reusable, allowing it to be dismantled and used for multiple projects. This not only reduces material costs but also enhances project scheduling by enabling concurrent construction activities. The ability to reuse steel formwork also minimizes the environmental impact of construction projects, aligning with sustainable practices. In summary, steel formwork enhances project coordination and scheduling by providing durability, accuracy, and reusability. Its efficiency and versatility contribute to faster construction timelines, reduced rework, and improved communication among various project stakeholders.

- Q: How does steel formwork affect the overall sound insulation of a structure?

- The overall sound insulation of a structure can be significantly influenced by steel formwork. Steel formwork, due to its dense and rigid nature, tends to transmit sound vibrations more efficiently compared to materials like wood or plastic. This means that extensive use of steel formwork in a building's construction can potentially reduce its sound insulation capabilities. The transmission of sound through steel formwork primarily occurs through three mechanisms: airborne sound, impact sound, and structure-borne sound. Airborne sound refers to sound waves traveling through the air and being transmitted through the steel formwork. Impact sound occurs when a sound wave hits the steel surface, causing it to vibrate and transmit the sound further. Structure-borne sound refers to vibrations traveling through the steel formwork and being transmitted to other parts of the building. To mitigate the negative impact of steel formwork on sound insulation, various measures can be taken. One approach is to incorporate additional sound-absorbing materials, such as acoustic panels or insulation, on the interior surfaces of the structure. These materials can help reduce the transmission of airborne sound waves and dampen the vibrations caused by impact or structure-borne sound. Additionally, proper sealing and jointing of the formwork can minimize sound leakage through gaps or cracks. It is important to recognize that the overall sound insulation of a structure is not solely determined by the formwork material. Other factors, such as wall thickness, insulation type, and the design of windows and doors, also play a crucial role. Therefore, while steel formwork may have a negative impact on sound insulation, it is possible to compensate for this by implementing appropriate acoustic design strategies and integrating soundproofing techniques throughout the building's construction process.

- Q: How does steel formwork contribute to the overall sustainability of a construction project?

- There are several ways in which steel formwork contributes to the overall sustainability of a construction project. To begin with, steel formwork is highly durable and can be reused multiple times. This means that less waste is generated during the construction process, unlike traditional timber formwork which is typically discarded after only a few uses. By reducing waste, steel formwork helps conserve natural resources and decreases the environmental impact of the construction project. Furthermore, steel formwork is renowned for its strength and stability, enabling the construction of more robust structures. Consequently, buildings constructed using steel formwork are likely to have a longer lifespan, reducing the need for frequent repairs or reconstruction. The longevity of steel formwork contributes to the overall sustainability of a construction project by minimizing the resources and energy required for maintenance and renovation over time. In addition, steel formwork allows for faster construction as it can be easily assembled and disassembled. The efficiency and speed of steel formwork result in shorter construction periods, which in turn reduces the energy consumption and carbon emissions associated with construction activities. This is especially crucial in today's fast-paced construction industry, where reducing time on site is a key factor in achieving sustainable development goals. Moreover, steel formwork provides a higher quality finish to concrete structures, which can enhance the overall energy efficiency of a building. A smooth and precise finish achieved through steel formwork can reduce the need for additional insulation or cladding, thereby decreasing the energy required for heating or cooling the building. This not only benefits the environment but also improves the energy efficiency and comfort of the occupants. In conclusion, steel formwork contributes to the overall sustainability of a construction project by reducing waste, increasing durability, shortening construction time, and improving energy efficiency. By opting for steel formwork, construction projects can adopt a more sustainable and environmentally friendly approach, benefiting both the immediate project and the long-term impact on our planet.

- Q: Can steel formwork be used in cultural or entertainment facility construction projects?

- Yes, steel formwork can be used in cultural or entertainment facility construction projects. Steel formwork offers several advantages such as durability, strength, and the ability to withstand heavy loads. These qualities make it suitable for constructing large and complex structures found in cultural and entertainment facilities, such as theaters, concert halls, museums, and stadiums. Additionally, steel formwork can be easily customized to meet the specific design requirements of these facilities, providing flexibility and efficiency in the construction process. Moreover, steel formwork is reusable, which can result in cost savings and reduced environmental impact. Overall, steel formwork is a viable option for cultural or entertainment facility construction projects due to its strength, durability, flexibility, and cost-effectiveness.

- Q: What are the standard dimensions of steel formwork panels?

- The specific requirements and preferences of construction projects can cause variations in the standard dimensions of steel formwork panels. However, the industry commonly employs certain standard dimensions. Typically, steel formwork panels are obtainable in standard lengths ranging from 1 to 3 meters (3 to 10 feet), with a standard width of approximately 0.6 meters (2 feet). The thickness of the steel panels can also differ, but it is typically around 12 to 16 millimeters (0.5 to 0.6 inches). These dimensions are intended to create a robust and durable formwork system capable of withstanding the pressures and forces experienced during concrete pouring and curing. Moreover, these dimensions facilitate easy handling and transportation of the formwork panels at the construction site. It is worth noting that the dimensions of steel formwork panels can be tailored to meet the specific requirements of a project. This adaptability enables the construction of unique formwork systems capable of accommodating diverse shapes and sizes of concrete structures.

- Q: How does steel formwork handle different concrete curing temperatures?

- Steel formwork is a highly durable and versatile construction material that is well-suited to handle different concrete curing temperatures. The key advantage of steel formwork is its ability to withstand high temperatures without deformation or structural damage. Concrete curing temperatures can vary depending on several factors, such as the climate, project specifications, and construction schedule. Steel formwork is designed to withstand these variations and maintain its structural integrity throughout the curing process. In instances where the concrete curing temperature is high, steel formwork effectively dissipates the heat due to its excellent thermal conductivity. This helps to prevent excessive heat buildup, which could potentially lead to premature curing or thermal cracking of the concrete. The steel formwork acts as a heat sink, absorbing and distributing the heat evenly, ensuring uniform curing throughout the concrete structure. On the other hand, steel formwork also performs well in low-temperature curing conditions. Its high tensile strength and rigidity allow it to withstand the pressure exerted by the cold concrete mix during the curing process. This prevents any distortion or deformation of the formwork, ensuring accurate and precise shaping of the concrete structure. Furthermore, steel formwork is also resistant to moisture and humidity, which are critical factors in curing concrete. It does not absorb water or release moisture, maintaining a consistent moisture content in the concrete during the curing process. This is particularly advantageous in areas with high humidity or where the curing time is extended. Overall, steel formwork is a reliable and robust material that can effectively handle different concrete curing temperatures. Its ability to dissipate heat, withstand cold temperatures, and resist moisture makes it a preferred choice for construction projects where temperature variations are a concern.

- Q: How does steel formwork handle different concrete mix designs?

- Steel formwork is known for its versatility and ability to effectively handle different concrete mix designs. The strength and durability of steel make it a suitable choice for accommodating a wide range of concrete mixes. One advantage of using steel formwork is its capability to withstand the pressure and weight of various concrete mix designs. Whether it is a high-strength mix or a mix with a higher water-cement ratio, steel can handle the load without any deformation or collapse. This makes it perfect for projects that require customized concrete mixes. Moreover, steel formwork ensures a smooth and even surface finish for concrete structures, regardless of the mix design. This is essential for achieving the desired aesthetic appearance of the finished product. Steel formwork guarantees that the concrete is properly contained, preventing any leaks or spills during the pouring process, resulting in a consistent and uniform finish. Additionally, steel formwork can be easily adjusted or modified to accommodate changes in concrete mix designs. Its adaptability allows for efficient construction processes and reduces the need for additional formwork materials. In summary, steel formwork is a reliable and efficient choice for handling different concrete mix designs. Its strength, durability, and adaptability make it an ideal solution for construction projects that require customized concrete mixes. Whether it is a high-strength mix or a mix with specific properties, steel formwork can effectively handle the demands of various concrete designs.

- Q: What are the different types of release agents used with steel formwork?

- There exist various release agents that can be utilized with steel formwork. Some of the most frequently encountered types encompass: 1. Water-based release agents: These release agents consist mainly of water, with additives like surfactants and lubricants. They are environmentally friendly and can be easily applied by spraying or brushing onto the steel formwork. By forming a thin film on the steel surface, water-based release agents prevent the concrete from adhering during the curing process. 2. Solvent-based release agents: Organic solvents serve as the carrier for the active ingredients in these release agents. They are effective in providing a smooth surface finish on the concrete and are often employed in situations where a higher level of release performance is required. Application is typically done through spraying or brushing, and the solvents evaporate quickly, leaving a thin film on the steel formwork. 3. Barrier release agents: These release agents are usually applied as a thick paste or gel, creating a physical barrier between the steel formwork and the concrete. They are commonly used when a high-quality surface finish is desired, such as in architectural concrete applications. Brushing or troweling the barrier release agents onto the steel formwork is the typical method of application. 4. Dry release agents: These agents come in powdered or granular form and are directly applied to the steel formwork. They create a non-stick surface by absorbing excess moisture from the concrete, thus preventing adhesion. Dry release agents are often employed in situations where other types of release agents may not be suitable, such as in cold weather conditions. 5. Form release oils: Petroleum-based products, known as form release oils, are frequently used in conjunction with steel formwork. They effectively establish a release barrier between the steel and the concrete, preventing adhesion. Application of form release oils is typically done through spraying or brushing, and they can be utilized in various concrete applications. The selection of the appropriate release agent is crucial and should be based on specific project requirements, including the desired surface finish, environmental considerations, and ease of application. Seeking guidance from professionals or consulting the manufacturer's recommendations can aid in determining the most suitable release agent for a particular steel formwork application.

- Q: Can steel formwork be used for sports complex construction projects?

- Sports complex construction projects can indeed utilize steel formwork. When it comes to shaping and building the necessary structures for such complexes, steel formwork proves to be a versatile and durable option. Its application extends to constructing walls, columns, beams, and slabs within the complex. Steel formwork possesses the strength and stability required for larger spans and higher load-bearing capacities, qualities often necessary for sports facilities. Moreover, the use of steel formwork yields a smooth finish, contributing to a professional and visually appealing appearance. In conclusion, steel formwork stands as a suitable choice for sports complex construction projects due to its strength, flexibility, and ability to efficiently create complex structures.

- Q: How does steel formwork affect the overall acoustic properties of the structure?

- Steel formwork does not have a significant impact on the overall acoustic properties of a structure. However, it may slightly reduce sound transmission due to its dense and rigid nature compared to other formwork materials such as wood or plastic.

Send your message to us

Steel-Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords