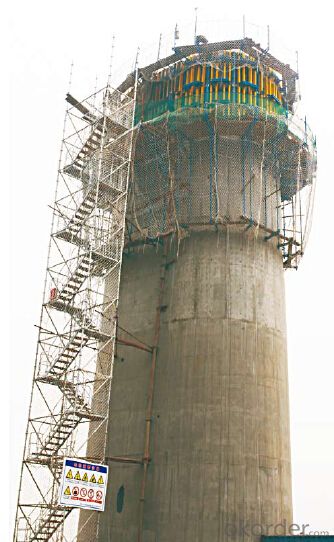

Stair Tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for underground parking structures?

- Yes, steel formwork can be used for underground parking structures. Steel formwork offers several advantages such as strength, durability, and the ability to withstand the pressure exerted by the surrounding soil. It provides a stable framework for pouring concrete and allows for quick and efficient construction of underground parking structures.

- Q: What are the common challenges associated with steel formwork?

- There are several common challenges associated with steel formwork in construction projects. One of the main challenges is the high initial cost of purchasing or renting steel formwork compared to other types of formwork materials such as wood or plastic. Steel formwork is more durable and has a longer lifespan, but the upfront investment can be a barrier for smaller construction companies or projects with limited budgets. Another challenge is the weight and handling of steel formwork. Steel is a heavy material, which can make it difficult to transport, assemble, and dismantle on the construction site. This can require additional labor and equipment, increasing the overall construction costs. Steel formwork also requires skilled labor for proper installation and alignment. The accuracy and precision of the formwork are crucial for achieving the desired dimensions and finishes of the concrete structures. Any mistakes or misalignments during the setup can lead to costly rework or compromised structural integrity. Maintenance and storage of steel formwork can be challenging as well. Steel formwork needs regular cleaning and treatment to prevent rust and corrosion, especially in humid or coastal areas. Adequate storage space is also required to protect the formwork from external elements when not in use. Lastly, customization and adaptability can be a challenge with steel formwork. Unlike wood formwork, which can be easily cut and shaped on-site, steel formwork requires prefabrication and customization before it can be used. Any changes in the design or dimensions during the construction process may require additional time and cost to modify or replace the steel formwork components. Despite these challenges, steel formwork offers numerous advantages such as durability, reusability, and high-quality finishes. With proper planning, training, and maintenance, these challenges can be effectively managed to ensure successful construction projects.

- Q: How does steel formwork handle concrete pump pressure?

- Steel formwork is highly durable and strong, allowing it to effectively handle concrete pump pressure. Its robust structure and rigidity help distribute and withstand the force exerted by the concrete pump, ensuring that the formwork maintains its shape and integrity during the pouring process. This enables the steel formwork to effectively contain and support the concrete, resulting in a successfully executed construction project.

- Q: What are the considerations when designing steel formwork for elevated slabs?

- When designing steel formwork for elevated slabs, there are several important considerations to keep in mind. Firstly, the structural integrity of the formwork must be ensured to support the weight of the concrete and any additional loads during construction. This involves determining the appropriate thickness and spacing of the steel members to provide sufficient strength and stability. Secondly, the formwork design should take into account the desired finish of the slab surface. The formwork should be designed to minimize any imperfections or surface irregularities, ensuring a smooth and even finish. This may involve using additional supports or bracing to prevent excessive deflection or sagging of the formwork during concrete pouring. Another crucial consideration is the ease of assembly and dismantling of the steel formwork. It should be designed in a way that allows for efficient and safe installation and removal, minimizing labor and time requirements. This may involve incorporating features like quick-release mechanisms, adjustable brackets, or modular components. Additionally, when designing steel formwork for elevated slabs, it is important to consider the impact of external factors such as wind, temperature, and concrete shrinkage. Adequate provisions must be made to account for these factors, ensuring that the formwork remains stable and in place throughout the construction process. Lastly, considerations for the reuse or recycling of the steel formwork should be taken into account. Designing the formwork in a way that allows for easy disassembly and reusability can help reduce waste and cost for future projects. Overall, the considerations when designing steel formwork for elevated slabs encompass structural integrity, surface finish, assembly and dismantling, external factors, and sustainability aspects.

- Q: How does steel formwork handle concrete curing compounds and sealers?

- Steel formwork is highly resistant to concrete curing compounds and sealers. Due to its non-porous surface, steel formwork prevents the penetration of these chemicals, ensuring that they do not interfere with the curing process or affect the quality of the concrete. Additionally, steel formwork is easy to clean and maintain, allowing for efficient removal of any residual compounds or sealers that may come into contact with it during construction.

- Q: What are the common types of steel used for formwork?

- The common types of steel used for formwork are mild steel and high-strength steel.

- Q: What are the different cost considerations associated with steel formwork?

- Some of the cost considerations associated with steel formwork include the initial purchase or rental cost of the formwork system, transportation and handling costs, installation and dismantling costs, maintenance and repair costs, and the potential for reusability and long-term cost savings compared to other formwork materials.

- Q: Can steel formwork be used for structures with high load-bearing requirements?

- Yes, steel formwork can be used for structures with high load-bearing requirements. Steel formwork is known for its strength, durability, and ability to withstand heavy loads, making it suitable for construction projects that require high load-bearing capacities. It provides stability and support during the concrete pouring process, ensuring that the structure can withstand the required loads once completed.

- Q: How does steel formwork affect the overall productivity of the construction process?

- The overall productivity of the construction process can be significantly influenced by steel formwork. Firstly, steel formwork is renowned for its durability and strength, enabling it to withstand the immense pressure and force exerted by concrete during pouring and curing. This durability ensures that the formwork remains intact and stable, reducing the need for repairs or replacements, thereby saving time and cost. Additionally, assembly and disassembly are made more efficient with steel formwork. Steel panels can be easily connected and detached, allowing for swift and seamless installation and removal. This ease of use ensures that construction can progress at a quicker pace, ultimately increasing overall productivity. Furthermore, steel formwork delivers a smooth and high-quality finish to concrete structures. The precise and rigid nature of steel formwork prevents any deformations or warping during pouring and curing stages, resulting in a superior surface finish. This eliminates the need for additional finishing work, such as plastering or smoothing, thereby reducing the time and effort required for post-construction tasks. Moreover, steel formwork is highly adaptable and can be customized to accommodate various shapes and sizes, facilitating the construction of complex structures with ease. This flexibility allows for greater design freedom and eliminates the necessity for additional supporting structures, ultimately reducing construction time and increasing productivity. Lastly, steel formwork is reusable and can be utilized for multiple projects, unlike traditional timber formwork which often requires disposal after a single use. This reusability not only reduces material waste but also saves time and cost in procuring new formwork for each project. In conclusion, steel formwork significantly enhances the overall productivity of the construction process. Its durability, ease of assembly, high-quality finish, adaptability, and reusability all contribute to faster construction timelines, reduced costs, and improved efficiency, making it a preferred choice for many construction projects.

- Q: How does steel formwork affect the overall aesthetics of a construction project?

- Steel formwork can have a significant impact on the overall aesthetics of a construction project. Unlike traditional timber formwork, steel formwork offers a sleek and modern appearance that can enhance the visual appeal of a structure. The clean lines and smooth surfaces created by steel formwork can give a building a more polished and sophisticated look. Additionally, steel formwork allows for greater precision and accuracy in shaping concrete, resulting in a more uniform and seamless finish. This can be particularly important in architectural designs that require intricate or complex shapes. The use of steel formwork ensures that the concrete is poured exactly as intended, leading to a more visually appealing end result. Furthermore, steel formwork is highly durable and resistant to wear and tear. Unlike timber formwork, it does not warp or deform over time, maintaining its structural integrity and aesthetic appeal for a longer period. This durability can contribute to the longevity and overall quality of a construction project, making it a more attractive investment for both owners and potential buyers. Another advantage of steel formwork is its adaptability. Steel can be easily molded and shaped into various sizes and configurations, allowing for greater design flexibility. This versatility enables architects and designers to create unique and eye-catching structures that can stand out from the crowd. In summary, the use of steel formwork in a construction project can have a positive impact on its overall aesthetics. Its sleek appearance, precise shaping capabilities, durability, and design flexibility all contribute to a visually appealing end result. Steel formwork can enhance the architectural design, create a more polished finish, and increase the longevity and value of the structure.

Send your message to us

Stair Tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords