Scaffold Formwork with Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

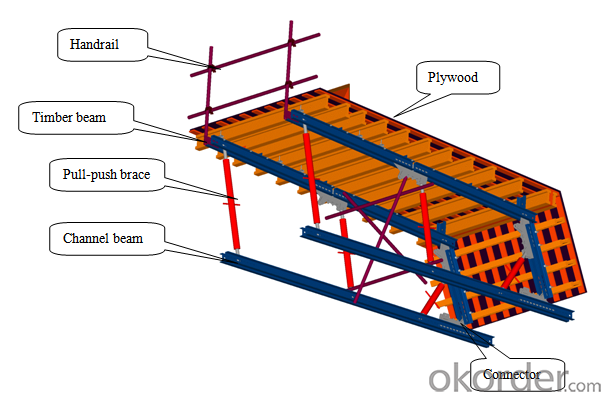

Light Weight Girder Box Formwork with Timber Beam , Channel Beam

Description:

Brief introduction

GB system-A is a kind of formwork especially for the bridge floor construction.

Competitive advantage

①. Prefabricated connection, convenient and efficient.

②. Light weight but high bearing capacity.

③. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

Applications

- Q: Can steel formwork be used in seismic areas?

- Yes, steel formwork can be used in seismic areas. Steel is a strong and durable material that can withstand the forces generated during an earthquake. Additionally, steel formwork provides a stable and rigid structure, which is important in seismic areas to ensure the safety and stability of the construction.

- Q: Can steel formwork be used for elevated concrete slabs?

- Indeed, elevated concrete slabs can be constructed using steel formwork. The usage of steel formwork presents numerous benefits in the construction of such slabs. Firstly, its robustness and durability enable it to withstand the weight and pressure exerted by the concrete. This quality is especially crucial for elevated slabs, as they must support the structure above them. Moreover, steel formwork guarantees a seamless and uniform surface, which is essential for achieving a superior quality finish on the concrete slab. It allows for precise shaping and detailing, ensuring that the slab meets the required specifications. Additionally, steel formwork is reusable, resulting in cost savings and environmental friendliness. By employing steel formwork, construction projects can minimize waste generation and reduce material expenses. In summary, due to its strength, durability, ability to provide a smooth finish, and cost-effectiveness, steel formwork proves to be an appropriate choice for the construction of elevated concrete slabs.

- Q: Can steel formwork be used for stadium construction projects?

- Yes, steel formwork can be used for stadium construction projects. Steel formwork refers to the use of steel panels and frames to create temporary molds or structures for pouring concrete. This method is widely used in construction projects, including stadium construction, due to its durability, strength, and reusability. Stadium construction projects often require large-scale concrete pouring for various elements such as foundations, beams, columns, and slabs. Steel formwork provides the necessary support and stability during the concrete pouring process, ensuring accurate and precise concrete placement. Moreover, steel formwork can withstand the high pressures of concrete pouring, making it suitable for large-scale projects like stadiums. Steel formwork also offers several advantages over traditional formwork materials such as timber or plywood. Firstly, steel formwork is highly durable and can be used for multiple construction cycles, making it cost-effective in the long run. Secondly, steel formwork provides better dimensional accuracy and consistency, resulting in better quality concrete structures. Additionally, steel formwork is fire-resistant, weather-resistant, and can be easily cleaned and maintained. Furthermore, steel formwork can be customized and fabricated according to the specific design requirements of the stadium. This flexibility allows for efficient and precise construction, ensuring that the stadium's structural elements are built to the desired specifications. In conclusion, steel formwork is a suitable and preferred choice for stadium construction projects. Its strength, durability, reusability, and customization options make it an ideal solution for creating temporary molds and structures during the concrete pouring process.

- Q: How is steel formwork disassembled?

- To ensure a safe and efficient removal, steel formwork is typically disassembled using a systematic approach. The process involves several steps that should be followed: 1. Begin with an inspection: Before disassembling the steel formwork, it is crucial to thoroughly inspect the structure for any signs of damage or wear. This step helps to identify potential hazards and allows for necessary repairs or replacements before starting the disassembly process. 2. Remove accessories: Start by carefully removing any accessories that are attached to the steel formwork, such as scaffolding, support beams, or tie rods. These accessories play a vital role in the stability of the formwork system, so their removal should be done with caution and control. 3. Clear concrete debris: Next, make sure to clear any concrete debris or remnants that may have adhered to the steel formwork. This can be done using tools like hammers, chisels, or wire brushes. Proper cleaning of the formwork ensures a smooth disassembly process and helps prevent any future complications. 4. Dismantle panels: Begin the process of dismantling the steel formwork panels one by one. This is typically achieved by removing the connecting pins, bolts, or screws that hold the panels together. It is important to follow the reverse order of the assembly process, starting from the top and gradually working downwards. 5. Handle and store: As each panel is disassembled, it is essential to handle it with care to avoid any damage or injury. Once disassembled, label the panels properly and store them in a designated area for easy retrieval in the future or for transportation purposes. 6. Conduct post-disassembly inspection: After the complete disassembly of the steel formwork, it is important to carry out a final inspection. This step allows for the identification of any damaged or worn-out components that may require repairs or replacement before the next use. In summary, the disassembly process of steel formwork necessitates careful planning, attention to detail, and adherence to safety guidelines. By following these steps, the formwork can be properly removed while maintaining the integrity of the structure and ensuring the safety of the workers involved.

- Q: What are the different types of supports used in steel formwork installation?

- There are several types of supports used in steel formwork installation, including adjustable steel props, timber props, soldier beams, and trusses. These supports are used to provide stability to the formwork system and ensure proper alignment and load distribution during the construction process.

- Q: How does steel formwork handle different concrete surface coloring techniques?

- Steel formwork is a versatile and durable material that effectively handles various concrete surface coloring techniques. The main advantage of using steel formwork lies in its smooth and non-porous surface, which guarantees even application of concrete coloring techniques and desired results. When it comes to concrete surface coloring techniques like staining, stamping, or integral coloring, steel formwork offers a stable and consistent foundation for these processes. The seamless surface of steel formwork allows for uniform and attractive distribution of colorants or pigments, ensuring a cohesive appearance of the final concrete surface. Moreover, the strength and rigidity of steel formwork make it suitable for different concrete surface coloring techniques. Whether it involves stamping, which necessitates the pressing of textured patterns onto the concrete surface, or staining, which requires precise application of colorants, steel formwork provides the necessary support and stability to execute these techniques accurately. Furthermore, the durability of steel formwork renders it resistant to damage during the coloring process. Concrete surface coloring techniques often involve the use of chemicals, dyes, or stains that can potentially harm weaker or less resistant formwork materials. However, the robustness of steel formwork allows it to withstand the harsh chemicals and coloring agents without compromising its structural integrity. In conclusion, steel formwork is an excellent choice for handling diverse concrete surface coloring techniques. Its smooth and non-porous surface ensures the even distribution of colorants, while its strength and rigidity provide the necessary support for techniques such as stamping or staining. Additionally, the durability of steel formwork protects it from damage caused by chemicals or coloring agents, ensuring a successful and visually pleasing outcome.

- Q: How does steel formwork handle formwork stripping time?

- Steel formwork is renowned for its durability and strength, characteristics that contribute to its exceptional efficiency in handling formwork stripping time. Unlike traditional wooden formwork, steel formwork has the capacity to endure multiple uses while maintaining its structural integrity. As a result, the stripping time required for steel formwork is significantly reduced when compared to other formwork materials. The rigid construction of steel formwork allows it to bear the weight of concrete and resist deformation during the pouring and curing processes. Consequently, the formwork can be removed more quickly once the concrete has set, as there is less concern about damaging or distorting the formwork. Furthermore, the design of steel formwork incorporates smooth and non-porous surfaces. This characteristic prevents the concrete from bonding with the formwork, facilitating an easier and faster stripping process. Additionally, the smooth surface contributes to a superior finish of the concrete, reducing the need for additional finishing work. Moreover, steel formwork systems often include adjustable features such as adjustable props and modular panels. These features enable easy adjustment and repositioning of the formwork, further enhancing the efficiency of the stripping process. This adaptability allows for faster stripping and reusability of the formwork, resulting in significant time and cost savings. In conclusion, steel formwork excels in managing formwork stripping time due to its durability, strength, and smooth surface. Its ability to withstand multiple uses, resist deformation, and prevent concrete adhesion makes steel formwork highly efficient and time-saving in the construction industry.

- Q: What types of structures can steel formwork be used for?

- Steel formwork can be used for various types of structures such as residential buildings, commercial complexes, industrial facilities, bridges, and even high-rise buildings.

- Q: Are there any specific considerations for using steel formwork in seismic zones?

- Yes, there are several specific considerations for using steel formwork in seismic zones. Firstly, steel formwork provides better strength and stiffness compared to other formwork materials such as wood or aluminum. This is crucial in seismic zones where the structure needs to withstand the lateral forces generated by an earthquake. The high strength of steel formwork helps in preventing deformation or failure during seismic events. Secondly, steel formwork offers better durability and reusability. In seismic zones, there is a higher likelihood of frequent earthquakes, and the formwork needs to withstand multiple cycles of loading and unloading. Steel formwork is known for its robustness and ability to withstand repeated use, making it suitable for seismic zones where regular formwork replacement may not be feasible. Another consideration is the design of the steel formwork panels. In seismic zones, it is important to ensure that the formwork panels have sufficient stiffness to resist lateral forces. This can be achieved by using thicker steel plates or adding stiffening elements to the formwork structure. Additionally, the joints between formwork panels should be well-designed and properly reinforced to resist the dynamic forces induced by earthquakes. Moreover, the connection between the steel formwork and the supporting structure should be carefully designed. In seismic zones, it is crucial to ensure a strong and rigid connection to prevent the formwork from detaching or collapsing during an earthquake. Adequate reinforcement, proper anchorage, and well-designed joint details are essential to ensure the stability of the formwork system under seismic loads. Lastly, it is important to consider the construction sequence and the timing of formwork removal in seismic zones. The formwork should be designed to provide sufficient lateral support to the concrete during the curing process, as premature removal of formwork can compromise the structural integrity. The formwork removal should be planned carefully to avoid any sudden changes in the load distribution that could potentially affect the seismic performance of the structure. In summary, when using steel formwork in seismic zones, considerations such as strength, durability, design, connection, and construction sequence are important to ensure the safety and stability of the formwork system and the overall structure during seismic events.

- Q: Can steel formwork be used for curved or irregularly shaped structures?

- Curved or irregularly shaped structures can definitely utilize steel formwork. Unlike traditional wood formwork, steel formwork offers greater flexibility and can effortlessly conform to any desired curve or irregular shape. This renders it a perfect option for constructing structures with distinctive architectural designs or intricate geometries. Furthermore, steel formwork boasts exceptional strength and durability, guaranteeing its ability to endure the pressures exerted during the concrete pouring process and retain its shape throughout the construction phase. All in all, steel formwork presents a versatile and dependable solution for shaping curved or irregularly shaped structures.

Send your message to us

Scaffold Formwork with Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords